In 2015, Ziemann Holvrieka was aiming to revolutionize the milling/brewing industry with the launch of its awesomely-named T-Rex mill. Over the years, this compact and innovative milling system has proven itself in breweries and distilleries worldwide, from German whisky producers to large-scale industrial brewhouses in Central America.

Just recently, Ziemann sent us an interesting technical report by Axel Hoffmann and Christopher Biechl, highlighting the T-Rex’s latest advancements. This got me wondering: After nearly 10 years, does the T-Rex mill continue to set the standard for modern grist milling technology? As Ziemann refines its flagship mill and expands its portfolio through strategic acquisitions, the company looks steadfast in its mission to support independent breweries with cutting-edge solutions. Let’s dig in.

A look back: The history of the T-Rex mill

Introduced in 2015, the T-Rex mill set out to address common challenges in grist milling. Traditional mills, such as roller mills and hammer mills, often came with high costs, limited versatility and energy inefficiency. Ziemann’s T-Rex mill broke these barriers, offering:

- Compatibility with both dry and wet milling.

- Compact and lightweight design.

- Innovative roller and disc technology.

- Energy-efficient operation with low maintenance demands.

From the recent technical report:

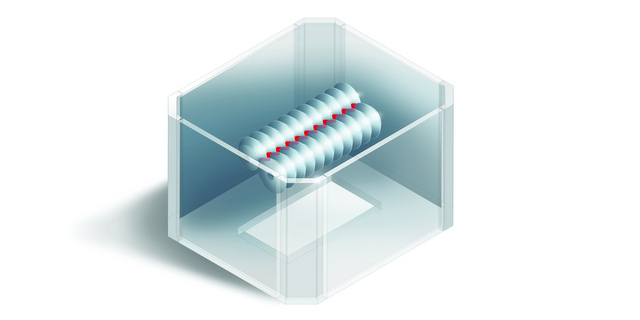

The milling principle of the T-Rex is characterized by high performance with low space and maintenance requirements. The technical developments described in this article build on these advantages. The centerpiece of the mill is the milling unit. This does not consist of cylindrical rollers, but of double-cone discs in toothed arrangement that form a zigzag-shaped milling gap. This arrangement achieves a large grinding surface in a small space. This enables a very compact, lightweight mill design, which places low demands on the building. Compared to cylindrical rollers, the grinding discs are small in volume and therefore lightweight. In a mill with a capacity of 20 t/h, a loaded roller weighs only approx. 100 kg. This makes the wear parts favorable and easy to transport.

Let’s dig in further.

T-Rex mill key features and specifications

The T-Rex mill stands out for its innovative design and robust performance, as recently highlighted in a technical report titled “T-Rex by Ziemann further optimised — focus on maximum customer benefit” by Hoffmann and Biechl. That report details what sets this mill apart from the competition:

- Dual milling options: The T-Rex DRY supports dry milling with capacities ranging from 5 t/h to 25 t/h. The T-Rex WET offers steep conditioning for wet milling, with capacities up to 25 t/h.

- Advanced grinding discs: Instead of cylindrical rollers, the T-Rex uses double-cone discs with a zigzag milling gap. The new design increases grinding surface area, efficiency and maintenance. “The edges of the grinding discs have now been provided with a special radius, which enables even utilization of the disc surface and makes the discs even more resistant to foreign bodies,” said the report. “At the same time, this rounding in the center of the double cone has been replicated, so that rounding now meets rounding. This results in an even abrasion over surface area and time, significantly extending the service life.”

- Durable materials: The grinding discs are available in chilled cast iron or stainless steel, ensuring durability and easy integration into cleaning processes.

- Ease of maintenance: The modular design allows for quick replacement of wear parts, reducing downtime to as little as two to three hours.

- Direct drive mechanism: Eliminates belts and gears, minimizing drive losses and accident risks while ensuring smoother operation. “No belts or gears were used to drive the grinding rollers. Instead, they are driven directly via a claw coupling,” said the technical report.

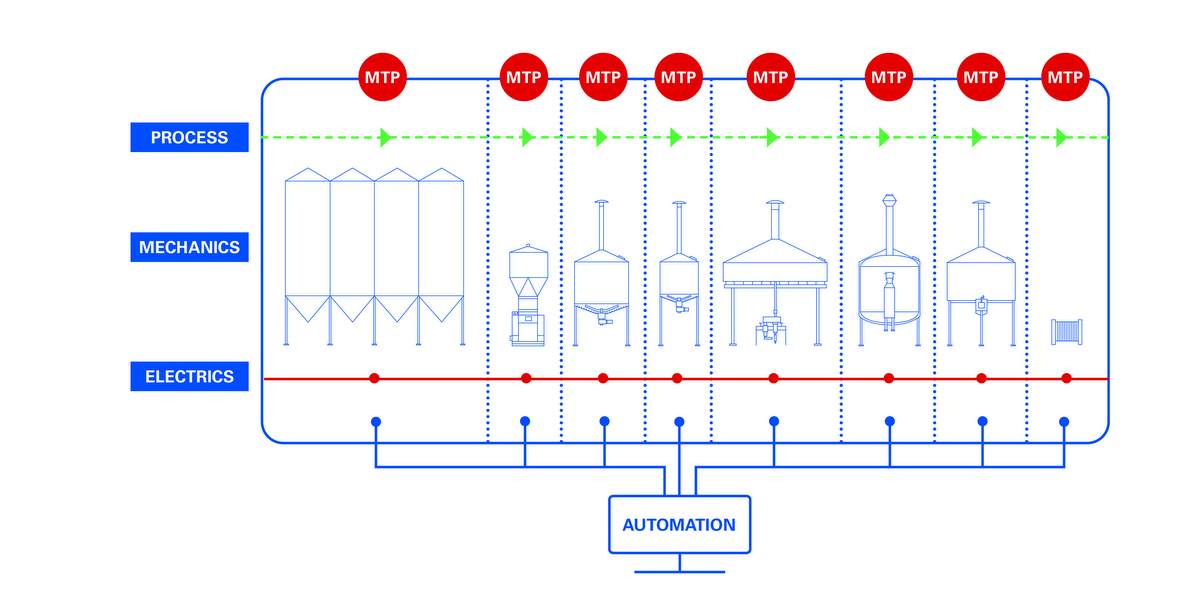

- Process integration: Sensors and an MTP file enable seamless integration into process control systems, making it compatible with modern brewing automation.

Recent updates = more efficiency

Ziemann’s latest advancements enhance the T-Rex’s already impressive capabilities.

- Extended disc life: Rounded edges on the grinding discs now provide even wear distribution, significantly increasing service life.

- Improved maintenance accessibility: Bearings and other components are easily accessible, requiring minimal adjustment during replacement. “The new, modular design of the grinding rollers with split shafts and a disc pack module makes it possible to replace the disc pack and all wear parts within around two to three hours, including a test run,” noted the technical report.

- Enhanced throughput: Feed grooves on the grinding surfaces ensure high throughput while preserving husks, improving overall grist quality.

Ziemann Holvrieka acquires Künzel

In a move to strengthen its position in malt handling, Ziemann Holvrieka recently acquired Künzel Maschinenbau. Künzel has been a leader in malt handling and grist mill technology since 1922. This acquisition allows Ziemann to combine its innovative brewing equipment with Künzel’s expertise, creating a comprehensive portfolio of solutions for breweries of all sizes. Künzel’s facilities and management team will remain intact, ensuring continuity while benefiting from Ziemann’s global presence and research capabilities. This partnership promises to drive innovation and expand market reach for both brands.

A new emblem for a new era

As part of its evolution, Ziemann Holvrieka introduced a modernized emblem late last year that reflects its commitment to innovation and heritage. The design incorporates elements of the company’s iconic tanks and vessels, symbolizing its forward-looking approach. This refreshed branding aligns with Ziemann’s focus on sustainable development and advanced technology. It’s a nod to the company’s legacy while positioning it as a leader in the brewing industry’s future.

Why the T-Rex Mill matters

The T-Rex mill offers breweries and distilleries a versatile, cost-effective solution for grist milling. Its compact design and advanced features reduce operational costs while improving grist quality. With options for dry and wet milling, it caters to diverse production needs. The addition of Künzel’s expertise and Ziemann’s updated branding further solidify the company’s role as a pioneer in brewing and milling technology. For independent breweries looking to optimize their processes, the T-Rex mill represents an interesting investment worth investigating.

Leave a Reply

You must be logged in to post a comment.