PakTech‘s signature product is its 100 percent post-consumer recycled (PCR) plastic carriers. They’re durable, user-friendly, environmentally responsible and an interesting option for craft brewers that can beer. Available in a variety of configurations, brewers can choose from handles that accommodate anywhere from two to six cans. Beyond manual packaging, PakTech also provides automated application equipment designed to integrate seamlessly into a brewery’s production line. This equipment helps in efficiently applying the can and bottle carriers, optimizing the packaging process.

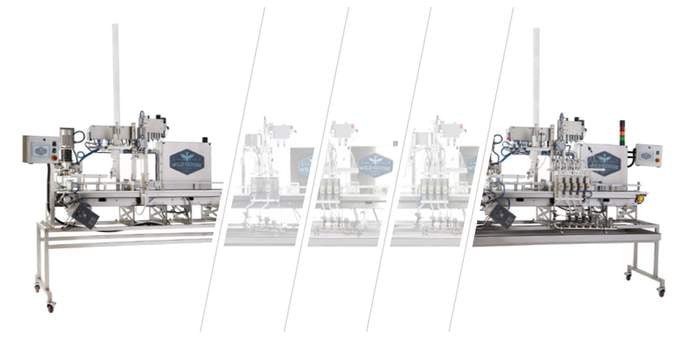

For instance, a craft brewery can quickly create multipacks of beer with this PakTech CCA 120/180 can carrier applicator. This machine applies PakTech Quad Pak, 6 Pak and 8 Pak can carriers to filled beverage cans. Just watch the video above. It is also easily adjustable for use on both 12- and 16-oz cans. It features a dual lane applicator that sends the cans through the system in two rows. It operates at 30 cycles per minute, allowing for 120 to 180 cans to be packaged per minute. Plus, this machine is easy to operate with an HMI touchscreen control.

The height of the conveyer can be adjusted 38 to 54 in. for comfortable use. It requires cans to be manually loaded into the feeder. Once loaded, the gripper assembles the cans and they are pneumatically driven for carrier application. The carrier type can quickly be changed without the need for tools, making it easy to create various pack sizes as needed. This unit requires a 120V electrical connection for operation. Here’s another breakdown.

Operation

- 30 cycle per minute on demand can carrier application rate

- Adjustments for 12- and 16-oz can application

- Operator required for manual loading of can carrier feeder

- Tool-less changeover between can carrier types

- Selectable in-line bypass mode

Design

- Dual Lane applicator to apply PakTech Quad Pak, 6 Pak and 8 Pak Can Carriers

- Cans accumulate in two rows

- Grippers collate cans for carrier application

- Cans are pneumatically driven through the application area

- UL listed industrial controls enclosure and CE certified machine

- Slide or straight feed conveyor layout options

- 38- to 54-in. top of conveyor height adjustment

Leave a Reply

You must be logged in to post a comment.