If you’ve been brewing for any length of time, it’s not unusual to start thinking about investing in your own canning line as a means to reach more people with your product. Many times, brewers will dip their toes in the water with mobile canning or contract packagers, just to get a feel for the canning process. But if you’re thinking about taking charge of your own canning operation, what are some things you need to know?

When shutdowns and taproom closures made it difficult to get product to customers, many brewers made the decision to evolve their business model and invest in canning line equipment. Around that time, we at Pneumatic Scale Angelus sat down to talk about packaging and what it means to the craft beverage community. We thought we’d share our thoughts on what you should consider when taking that next big step.

“Start at the packaging end! Make those investments first!”

An early customer of PSA’s CB100 open-air canning line, Dan Kopman, CEO of Heavy Seas Brewery, has famously said that if you’re going to brew your own beer, you should really be thinking of how you’re going to package it before you even brew it. From Dan’s perspective, if you spend all that time making great beer, why would you risk degrading the quality of it by putting it in the wrong package?

We happen to agree with that line of thinking – it’s actually why we first got into the business of building canning lines for the craft beverage community nearly ten years ago, and it’s why we continue to prioritize innovation in our designs.

After more than a century of leading the high-speed beverage industry with our Angelus can-seaming technology, scaling that expertise for the needs of smaller brewers seemed like a worthy challenge for our engineering team.

Starting out with a single-head seamer to close the can, we quickly realized that it made sense to also incorporate our filling experience into the design, to create an integrated canning line capable of serving both halves of the operation. And we haven’t stopped since, designing a portfolio that continues to grow to accommodate larger volumes and faster speeds as a brewery’s operations grow. We’ve learned a lot along the way, and we’re thrilled when we get to share those lessons with brewers contemplating that next step.

Thinking through the line

Focusing on how you package your product is essential to ensure you get the best beer possible into the hands of your customers.

Mike Davis, Product Line and Technology Leader for PSA (which is part of the larger BW Packaging company), notes “It’s a big step and a significant business decision to invest in canning machinery, so we approach it as forming a partnership with the brewery, learning all about their production needs and goals, their product mix, and preferred packaging formats.”

It’s important to think through the entire line. Any new packaging-related machinery must be compatible with any current filling or can seaming systems the brewery already has, as well as the upstream and downstream equipment.

Brewers also need to factor in other variables like:

- the available utility supply for things like carbonation and chilling,

- the need for space for other desired packaging machinery like accumulation tables or depalletizers, and

- the available space for supplies and finished goods and shipping.

“A craft beverage packaging system must also include a quality CIP (Clean-In-Place) system,” said Davis. “Craft beer is typically not pasteurized, so it’s critical to keep everything clean that comes in contact with your product to keep any chance of spoilage away.”

Overcoming the nerves

“Purchasing or upgrading packaging lines can be overwhelming for brewers who haven’t been exposed to the packaging side of things before,” said Adam Brandt, VP of New Equipment Sales for PSA. “But by comparing the cost of purchasing versus the potential drawbacks of working according to a mobile canner or copacker’s schedule, it’s easy to see how owning their own line has distinct advantages for a craft beverage producer.”

In addition to being able to package products according to the schedule that makes sense for the brewery rather than having to wait for an open slot on someone else’s schedule, craft brewers can control variables critical to production parameters like Dissolved Oxygen (DO) and carbonation levels.

As a brewer, you can package as much or as little as you want, and even test new products on the market with smaller batches, expanding your e-commerce and customer reach with more frequent and unique offerings. And in the process, you’ll build relationships and important networks with suppliers and distributors.

“Having an available packaging line can immediately open additional opportunities for a brewer,” said Brandt. “Owning your line means the canning operation is available when needed. Additionally, craft producers can partner with other breweries to become their copackers to help offset costs while keeping the packaging lines running.”

Some breweries have even partnered with community organizations or local sports teams for fundraising or charitable collaborations.

Finding a system that’s right for you

Packaging equipment at its most basic level depends on your goals.

- Do you want to stay local and build upon small-batch taproom offerings?

- Is future distribution part of your business plan?

- Can your equipment and utility supply match future goals or be upgraded to do so?

- What about your production footprint? Can you expand raw material storage and your finished goods area?

- And what about personnel? Do you have people to devote more time to packaging without making yourself work 16-hour days?

Production capability and compatible goals are critical throughout the packaging process, including seaming and filling technology. Breweries need technology to be repeatable to provide consistency while also being versatile enough to adapt to things like cans from different suppliers that may have different tolerances or variability in your product mix. Different products like beer, cider, kombucha and RTD (ready-to-drink) drive changeover needs, and you want your equipment to be able to keep that changeover time to a minimum.

“Also, be sure that you look for packaging machinery that features upgradeable and transferable technology that is user friendly,” said Davis.

- Can it be adjusted to match your utility supplies and desired DO and carbonation levels?

- Can you vary the amount of foam delivered for different brews?

- How does the machine flow – does it ensure closure of the can as quickly as possible, ensuring accuracy and consistency?

- And does the supplier offer exceptional support and available, in-stock parts?

- Most importantly, do they provide you with training on the equipment, and is it intuitive enough to give you confidence in your ability to be self-sufficient in running it?

Protecting your brand

Packaging informs the first impression consumers have of your product, and it’s a critical element in building your brand. The proper packaging system will ensure that your canned beverage will consistently taste as intended, and that it’s just as good as if it was freshly poured in the taproom.

Learn More!

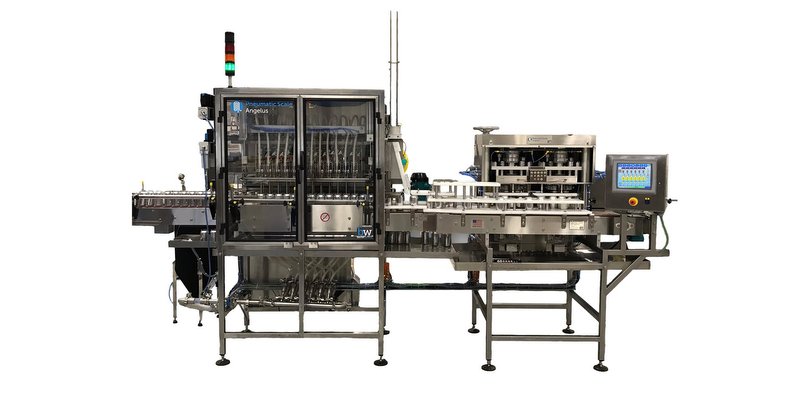

PSA uses the innovation of our high-speed lines in our slower-speed, lower production units for craft beverage producers.

Our inline canning units, like the CB50F and CB100F, are open-air systems with proprietary flowmeter technology and a gas-flush system for oxygen level control and are suited for small batch production with frequent changeovers and run at speeds of 15 to 100 CPM (cans per minute).

In addition, the CB50C and CB100C use counter-pressure filling technology to meet the increased demand for higher-carb beers, sparkling wines, and seltzers. The CB100C is a rotary counter pressure system using a 12-head rotary filling turret coupled with a dual seamer to increase throughput. The gentle filling action diminishes agitation, keeping carbonation levels up to the brewer’s standards.

For additional information about these products and how they can improve your packaging process, reach out to Gigi Lorence, Global Marketing Director, at [email protected].

Leave a Reply

You must be logged in to post a comment.