There are lots of cool hop products on today’s beer market besides whole cones and pellets — cryo hops, hop haze, hop hash and a lot of liquid hop options like extract. While some of these products are new innovations, hop extracts have been around for decades, often used by big brewers for their convenience and cost. Traditionally, craft brewers have shied away from doing what big brewers do and are often committed by category to utilizing high-quality ingredients and poopooing biotech alternatives.

Well, over the years extracts have grown in popularity with both craft brewers and suppliers. Today, everyone from Yakima Chief Hops to BSG offers a hop extract, and now there’s a new player called Abstrax, which just launched its Optimized Hop Extracts product line, citing a patent-pending process for creating highly specific hop varietal extracts without synthetic carriers or any of the undesirable flavor notes sometimes found in dry-hop aroma oils. From the press release:

“I work with our customers to help them fill in the gaps and educate them on the power of this technology,” said [Ross] Hunsinger, [director of food and beverage innovation for Abstrax and a Siebel Institute Alum]. “They’re literally blown away by how easy it is for them to innovate new products and infuse them with the very best optimized hop extracts at a fraction of the cost — including unforgettable craft beers, refreshing hops seltzer waters, delicious nonalcoholic beers, and more.”

The benefits of extracts are many. Large breweries understand them. They can save money, effort, time and can produce an equally great beer if you know what you’re doing. What makes Abstrax unique? Leveraging a background in strain research, Abstrax is a leader in the study and production of cannabis and botanically derived terpenes. Headquartered in California, the company owns and operates a state-of-the-art type 7 licensed research and manufacturing lab in Tustin. The company noted it uses proprietary technology to test for well over 400 botanical compounds found in hops, and that other labs test for maybe 50 compounds at most.

“Abstrax is positioned to be the leader in an emerging world of terpenes. They have been extremely intentional investing both time and money into their expertise,” said Michael Roy, President and CEO of Roy Farms. “What started in cannabis is now broadening in scope to include brewing. I see this as a natural fit and one that aligns with the hop and larger brewing industry as they look to efficiencies and sustainability initiatives in an effort to meet both the business and consumer needs.”

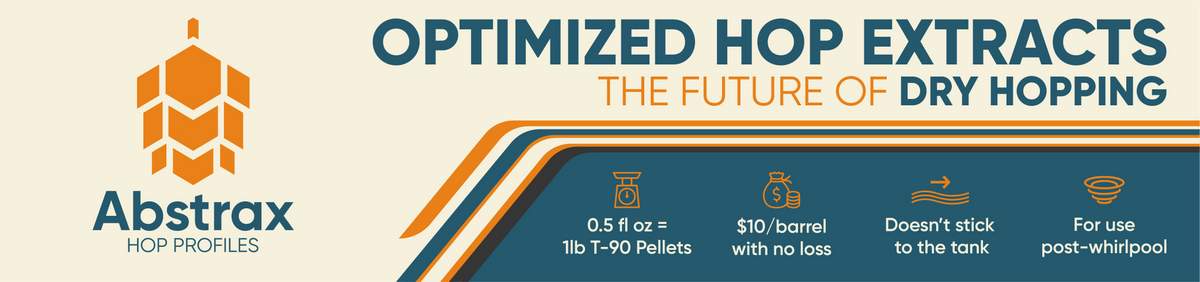

With its Optimized Hop Extract products, the company is promising no hop creep, no tank sticking, no lightstruck flavors and then no solvents or synthetic carriers, giving the product a greener halo. Here’s more info in picture form:

It’s not just cannabis and beer. Abstrax is looking at product applications beyond beer such as RTD cocktails, seltzers, hop waters and non-alcoholic functional beverages that require an out-of-the-box approach to formulation. And, as cannabis continues to make its way into the mainstream, Abstrax noted its going to leverage its cannabis research and knowledge to create similarly novel ingredients, such as botanically derived terpenes, along with superior extraction and distillation methods. More specifically, Abstrax uses the following steps to help brands produce craft beer and beyond beer innovations:

- Step 1 – Fresh Hops are tested and 3D modeling of the target hop profile is undertaken.

- Step 2 – Input materials are selected, extracted, and refined.

- Step 3 – Botanical ingredient standardization and molecular distillation is done.

- Step 4 – Varietal specific custom formulations are reproduced.

- Step 5 – (Optional) Customize flavor, aroma, or effect profile.

- Step 6 – Select the final application (Oil-Soluble, Water-Soluble Liquid or Powder).

According to Abstrax, brewers that are utilizing these extracts are seeing significant savings as a result of the following factors:

- Lower ingredient cost per barrel with no loss

- Up to 75 percent dry hopping supplementation

- 0.5-fl-oz can supplement up to 1 lb of T-90 pellets

- Increased efficiency and beer throughput up to 30 percent from reduced product loss

- Reduce dependency on fresh hop materials

- Guaranteed flavor and aroma consistency

- Increased speed to market of new hop-infused products

- Less water is required during the brewing process

- Doesn’t stick to the tank

- Labor and materials are reduced due to quicker turnaround time on tanks

- The upcycling of unused hops materials is highly cost-effective

- R&D innovation costs are slashed as Abstrax carries this weight

- Customization of products through advanced sensory analytics

- Increased product shelf life from 30 days to 60 days

To best serve its customers, Abstrax also noted it’s working to create a “living record” of the best hop varietals from around the world that can be reproduced on demand. So if climate change reeks havoc on our hop supply chains (think fires in the Pacific Northwest), we can still make some good tasting beer.

“Not only will this living record provide convenience, but it also protects the industry against all odds if environment and market factors challenge the status quo of the brewing industry,” said [Max] Koby, [Abstrax cofounder and CEO].

For more information on Abstrax and its hops-related products click here.

Leave a Reply

You must be logged in to post a comment.