The next time you’re enjoying a refreshingly cold craft beer, feel free to make a toast in appreciation of the hardworking screens, pumps and skimmers that ensured the brewery could process its high volume of wastewater. Well, perhaps don’t dwell too long on the realization that the process equipment manufactured by Tsurumi Pump is just as much at home in a microbrewery as it is in a small-town wastewater treatment plant. Indeed, the procedures for treating these very different types of wastewater are surprisingly similar, but how does all of that process equipment ensure that even the most polluted wastewater ultimately leaves the plant clean enough to safely re-enter the environment?

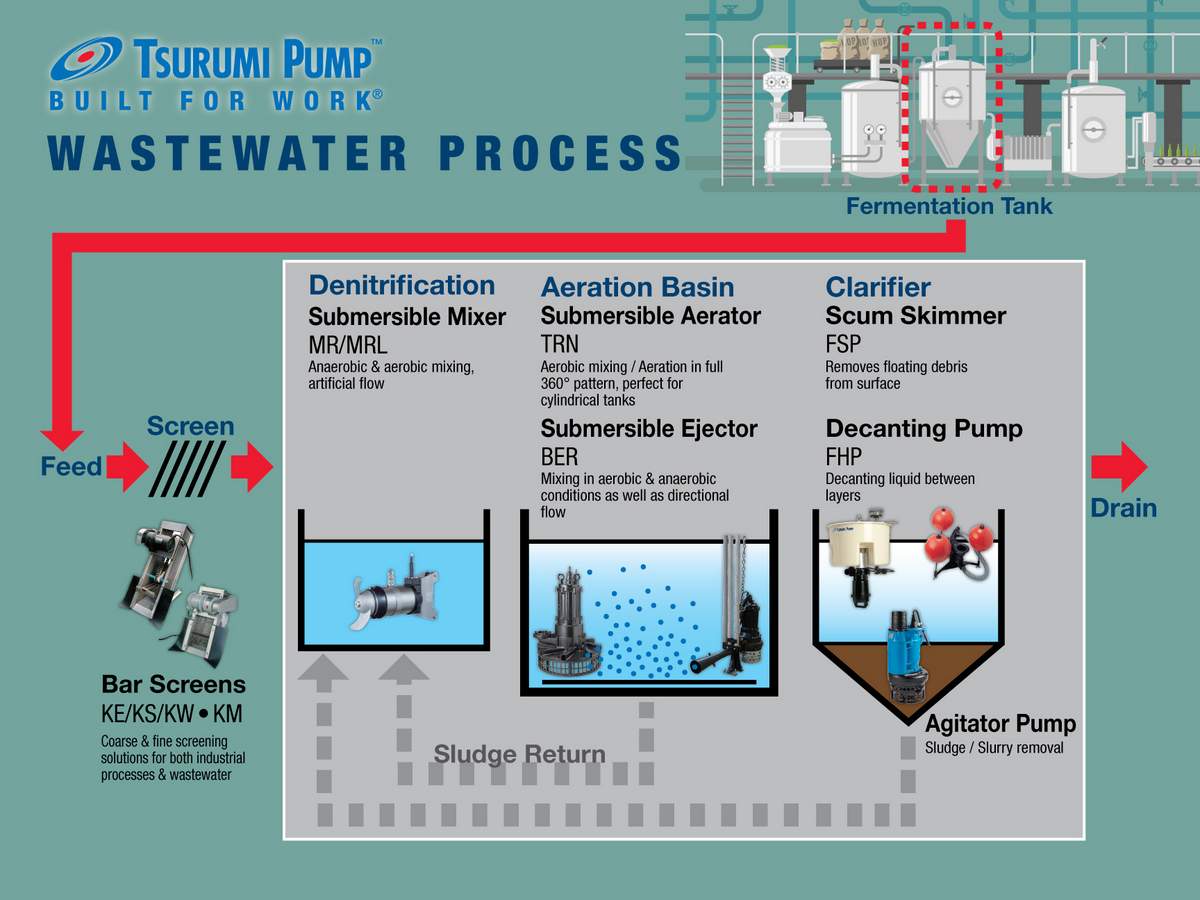

Once it’s been siphoned off from the brewery’s fermentation tanks, the first obstacle the water must overcome on its journey to the ocean will inevitably be pre-treatment through an automatic bar screen. While sewage plants commonly rely on Tsurumi’s KE, KS, KW and KM coarse-screen models to form an early, effective barrier against waste both large and small, from sanitary wipes to shoes and plastic bottles, most breweries will find the finer-screened debris in the same ranges to be sufficient.

Offering a range of bar spacings from 1 – 5 mm and 10 – 50 mm, the KE, KS and KW front-screeners and KM rear-screeners will filter out a variety of tiny solids and sediment, further reducing the risk of damage to the pumps and valves of the downstream equipment. Each model has two or more rakes, powered by an economical, small-output motor, that move between the screen bars, scraping out solid matter before clogging can occur. The waste is then moved to the screen top before it is discharged to the transporter or waste bin by gravity slide.

“Our bar screens provide excellent durability in even the harshest environments,” said Glenn Wieczorek, managing director of Tsurumi Pump. “We rely on 304 and 316 stainless steel for enhanced corrosion resistance and include no revolving parts in the submersible section. For instance, we offer both traditional chain-driven rake type [wet] and a type of catenary [dry] chain type; where the chain and sprockets avoid contact with the liquid and therefore requires virtually no maintenance.”

Next stop: nitrification/denitrification

Just as with sewage, denitrification of wastewater is the next key treatment stage in the brewing process due to the increased levels of nitrogen that is produced from the proteins in the grains. Both industries will adopt biological treatments such as nitrate-reducing (denitrifying) bacteria to tackle this, aided by anaerobic and/or aerobic mixing to stimulate flow.

Tsurumi’s extensive range of MR and MRL submersible mixers is suitable for use in all commonly encountered water levels in these industries. Like the bar screens, these models are also extremely cost-efficient, with output from their submersible motors ranging from just 0.33 hp to 5.56 hp. These motors are directly coupled to a high-efficiency propeller that generates a powerful jet of water, enabling either aerobic/aeration treatment by mixing air and water or purely anaerobic treatment.

The coverage of the MR series has been boosted by offering configurations with or without a guide ring (increasing the flow-regulating effect, or improving the mixing effect and increasing water flow, respectively), thereby enabling each mixer to be precisely matched to its application. Flow rates ranging from 370 – 4,914 gallons per minute (gpm) are therefore possible.

For applications in shallow (below 500 mm) water, the MRL series of mixers will provide anaerobic mixing at flows of up to 2,985 gpm. With an agitation output of up to 3.1 hp (under clear water), they are fitted with a guide ring that extends to the rear, preventing whirlpools from being sucked in, and making them particularly effective for mixing water in flow-regulating tanks. Available in cast iron or stainless steel constructions, they are also ideal for applications such as environmental conservation in ponds and rivers or enhancing artificial water flow in parks and recreational facilities.

A breath of fresh air

Stimulating the natural process of bacteria breaking down organic material is at the heart of the next stage of the treatment process, and is encouraged by pumping oxygen into the tank and/or aggressively agitating the water.

By providing aeration over the surrounding 360 degrees, the TRN self-aspirating submersible mixer/aerator is perfect for promoting aerobic mixing in cylindrical tanks and can operate as low as 20 ft deep and even greater depths when simply using the draft tube or supplemental blower system. With output ranging from 1 – 54 hp, they produce a strong flow of water mixed with air that ensures every part of the tank is aerated and that no sediment is formed.

Directly connected to the motor shaft, its rotor causes a circular movement of the water, resulting in negative pressure around it. Air is then automatically brought in from above through the suction line, before being intensively mixed with the water flowing into the area around the rotor. This forms thousands of microscopic air bubbles that are spun radially outwards at high speeds through the channels of the guide vane, reaching every part of the tank to ensure the water is uniformly oxygenated.

“It’s vital that this hard-working mixer provides the highest durability, so we start with the obvious — the casing is solid cast iron, and parts that are subject to particular wear such as the shaft, screws, the impeller, and suction plate are built from stainless steel,” Wieczorek said.

“The hollow tip of the impeller allows an air cushion to be formed, which prevents the shaft seal from touching water and greatly increases its lifespan. Also, the bearings and the oil bath around the shaft seal are oversized, so whether it’s working in a brewery, a slaughterhouse, or a sewage treatment site, the TRN will deliver fault-free 24-hour operation.”

Alternatively, the Tsurumi BER series of submersible ejectors can be utilized to deliver the highest levels of mixing and oxygen transfer. Ideal for Sequence Batch Reactor treatment systems, this aspirating aerator combines a submersible pump with a venturi jet-based diffuser to eliminate the need for blowers, air piping, and compressed air. The ejection current generates a self-feeding, negative pressure around the nozzle that draws air from the surface through an inlet pipe, mixes it with the water below, and then ejects the mixture. The result is a remarkably strong churning force that produces exceptionally efficient oxygen dissolution across a wide area.

“The BER is a very flexible option,” continued Wieczorek. “Successful applications include sewage treatment plants in small towns that had previously struggled to deal with the tripling of its wastewater during the summer season.”

A major clarification

Once the wastewater reaches the clarification stage of the process, the focus turns to sludge removal. First, all floating debris will be removed from the water’s surface. Tsurumi’s FSP floating scum skimmer consists of a submersible pump, jet-injector mechanism, three floats, and relies on the Venturi principle to remove floating oils and grease solids with a minimal amount of water. A bypass attached to the discharge opening recycles part of the pumped water to the intake to generate a jet flow, resulting in the generation of consistent, stable suction power in the collection cup, or intake.

The floats enable its submersion depth to be set to a single millimeter if desired, maintaining this distance regardless of changes in water level. A simple twist of the floats, however, can quickly increase flow by setting the suction mouth deeper (up to 60 mm), with the scum then being pumped to the concentration tank for processing.

Again, with a power output ranging from 1/2 to 1 hp, the FSP is an extremely economical option and has been successfully employed to remove a variety of other floating debris, ranging from duckweed to oil spills.

Operating in the same secondary clarifying tank, just beneath the level of the scum skimmer, will be a floating decanting pump tasked with discharging supernatant liquid — which should now be approaching expected effluent specifications — to the drain when used in a brewery application. With outputs from 1/3 – 2 hp, Tsurumi’s comprehensive range of FHP solutions comprises a float that keeps the submersible pump stable even in basins with strong flows and a photosensor. When this detects decreasing water purity near the inlet, a floating ball valve incorporated in the intake switches off the pump to prevent the inflow of sludge and sediment.

At this stage, the only remaining process is the handling of sludge return and slurry removal. Here, very small solids, or ‘fines’ will have sunk to the bottom of the tank, but rather than it all being collected for use as fertilizer, some of this activated sludge will be returned to the upstream denitrification and aeration tanks to kickstart the breakdown of organic material.

For easy removal of the sludge, an agitator pump will be required to homogenize the medium. Tsurumi offers a huge choice of suitable models, but a long-time favorite with brewers has been its VANCS PU series of resin-made pumps with a vortex impeller that ensures virtually unshakeable operation. The use of 304 stainless steel further enhances its corrosion resistance, while the use of liquid paraffin as its lubricating oil widens its application to high-grade installations such as decorative waterfalls, fishponds, and aquaculture.

“Our process equipment is so flexible that it can be used across several industries, whether for wastewater, chemical processing, or food-processing applications,” Wieczorek concluded. “One of the key features is the way that this equipment works in conjunction with the pumps, ensuring the most efficient operations while allowing us to be a one-stop-shop where customers can get all of their pump needs in one place. That’s definitely worth raising a glass to!”

For more information on Tsurumi’s process equipment, click here.

Leave a Reply

You must be logged in to post a comment.