The Craft Brewers Conference and BrewExpo America is taking place May 2 -5 in Minneapolis, packed again with the latest and greatest innovations for building and running an indie beer business. The expo itself can be rather overwhelming, until you switch to “sampling,” of course, and then forget about it altogether. Anyway, to help you efficiently navigate the trade show floor, see all you need to see, and get to that “networking” quicker, we asked exhibitors to give us a sneak peek. Here are those peeks, listed in order by booth number.

Register for Arryved’s Smash Your Craft Block Party

Arryved | #119

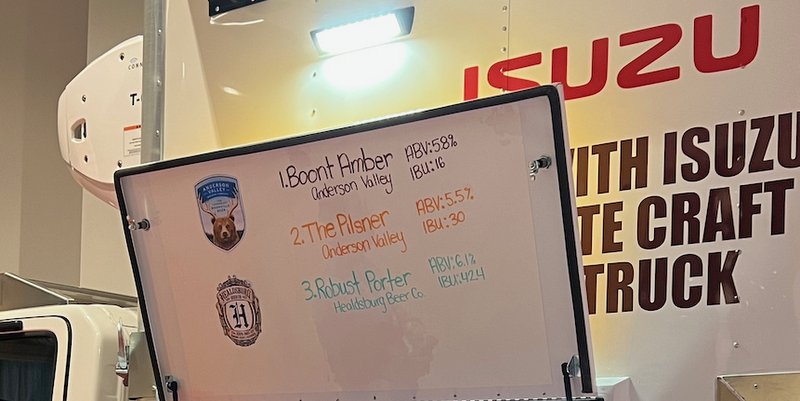

Yes, you can hit up Arryved’s booth to see its POS in action as well as update your sock and hat collection. But you’re also not going to want to miss its Smash Your Craft Block Party at Forgotten Star Brewery with ABS Commercial on May 4, from 4-7pm. Here’s what’s on tap:

- Craft beer and liquor pouring

- 3 of Minneapolis’ finest food trucks

- Car smashing

- Live music with some Prince covers

- Bocce ball court

Oh, and it’s all FREE, including the party buses to get you there from the Convention Center. Register your team here.

INX International adds to Color Perfection Program

INX International | #327

INX International’s Color Perfection program might be the best true color standard in the industry. In addition to helping produce a more efficient design-to-market process, there are significant cost savings advantages, brand consistency and color accuracy considerations that are proving to be very beneficial.

INX continuously updates this multi-level program. Besides the INX 2-Piece Metal Color Catalog and corresponding digital color library, it includes digital printing and an educational platform with free courses available from INX University. The catalog will be available to review in the booth.

BTW: In May 2021, Great Lakes Brewing Co. was voted the winner of the Colored by INX Can Design contest, and several INX colors were used to illustrate the unique design for Crushworthy Lo-Cal Citrus Wheat beer. Entries for this year’s contest must be postmarked by April 29. So, do that before you leave.

Labeltronix adds shrink sleeves to craft beer labeling capabilities

Labeltronix | #737

Labeltronix provides high quality embellished labels on bottles, metallized labels on cans and now, thanks to a shrink sleeve supply from its partner, AWT Labels & Packaging, they will now be offering shrink sleeve printing. With the increase in costs and huge minimum order requirements for can printing, brewers are turning to can labels and shrink sleeves to stand out on shelves. Shrink sleeves benefits include 360 degrees of visibility, a tactile feel, waterproof labels, variable options (such as giveaways, games, QR codes) and a manageable inventory (no longer need to order a large number of cans with just a single SKU).

Crafted ERP has a new distributor portal to show you

Crafted ERP by Doozy Solutions | #827

Crafted ERP by Doozy Solutions enables breweries to automate and streamline every aspect of their businesses. Developed by brewers for brewers on NetSuite, Crafted provides a 360-degree view of the real-time, cross-operational information necessary to increase revenue, customer loyalty and shareholder value. Many brewery systems stop at production, making insights into profitability, sustainability and customer behavior nearly impossible to attain. Crafted ERP can do much more, linking accounting and back office functions with every aspect of your operations. At CBC, check out its new distributor communication portal and give their dev team feedback on what you’d like to see in your software platform.

Mueller brings smaller, customizable craft brewery packages to CBC 2022

Paul Mueller Company | #1339

Paul Mueller Co. is bringing its new, smaller capacity Beer Genius craft brewery packages (5 to 30 bbl) to the 2022 Craft Brewers Conference this year. Mueller brewing experts will be on hand at booth 1339 to guide booth visitors through the options for fully customizing their brewery dimensions, layout and processes. A Beer Genius brewhouse, serving tanks and chiller will be displayed at the conference, giving attendees an opportunity to see the equipment quality and features in person.

Mueller is also promoting a new 3D Brewery Planner available on their website that helps customers visualize their brewery equipment in their space. Users can customize their brewery layout from top to bottom in 3D – starting from scratch in an empty brewery, or beginning with one of three themed brewery templates.

MadBrew STONE ACID removes scale, hard water deposits

Madison Chemical | #1434

Madison Chemical’s MadBrew STONE ACID is a specially inhibited, low foam acid blend for the removal of hard water deposits and scale, extract from wort, lipids from hop compounds, and more. It will be featured along with other MadBrew products at the show. STONE ACID dissolves the crystalline molecular structure of the calcium carbonate which permits the complete removal of the deposits from the kettle, heat exchanger or other equipment. It is ideal for stainless steel and copper alloys when used as directed, MadBrew STONE ACID is recommended for use prior to Enviro-Clean BOIL-OUT on hot side brew house cleaning applications, and in advance of Enviro-Clean BOIL OUT on heat exchangers. Recommended dilutions are dependent on factors such as calcium hardness, the composition of the wort extract, and the number of brews between cleanings.

CanSource has a new plant and great lead times to tell you about

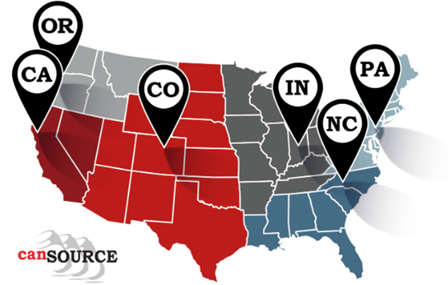

CanSource | #1742

Since its founding over a decade ago, CanSource has grown alongside the craft beer industry and its transition from bottles to cans. What started as a homegrown mobile canning operation in Colorado, has evolved into a national one-stop-shop for cans. CanSource’s newest plant located in Indianapolis is the company’s first location in the Midwest and the sixth location across the United States. The plant opened at the start of 2022 and follows the addition of a plant in Portland, Oregon a year ago in 2021.

CanSource is also offering printed and brite cans alongside their current sleeved can portfolio. Using their strategic partnership with Ball Corporation, CanSource is now providing one truckload minimums for printed cans across the US. With this network, CanSource says it can offer best-in-class lead times year-round.

Check out these exclusive HAAS hops

HAAS | #1819

Representatives from HAAS’ global distribution network will be hanging at the booth, and as always, they will have great beers on tap showcasing INCOGNITO, LUPOMAX and Spectrum—along with exclusive hops like Adeena ADHA 1940 c.v. and Azacca ADHA 483 c.v., French Hops and more!

Thielmann is showing off its new Corny keg

Thielmann | #2229

Thielmann’s portfolio comprises all standard US beverage kegs, aseptic IBCs with 264 gal capacity for fermentation, carbonation, and yeast propagation, small industrial containers in various sizes, plant components, and more. They are all engineered from AISI 304/AISI 316 austenitic stainless steel. This year, they are introducing the new Corny keg, which they say is more durable, reliable, and cost-effective. Manual access via the oval handhole makes opening, filling, and cleaning much easier, with the potential to eliminate the need for industrial filling and washing equipment.

Roberts PolyPro has a new can carrier applicator

Roberts PolyPro | #2435

Roberts PolyPro is introducing its new can carrier applicator, ICHA-60, which applies its plastic 4-pack and 6-pack Craft-Pak carriers to standard and sleek cans at speeds up to 10 cycles per minute. The ICHA-60 offers a reliable process through the canning line with continuous handle application that requires minimal operator input. It features a small footprint to fit in a single file canning line, as well as a simple changeover from 12 to 16 oz. cans that requires minimal parts and can be completed in under 15 minutes.

Ekos is demoing new levels (and management) of system connectivity

Ekos | #2525

Ekos, a top business management software for craft beverage businesses, is focused on helping breweries of all sizes use technology to their best advantage so they can grow, even in challenging times. With a comprehensive end-to-end software solution, Ekos helps brewery owners and managers connect data across the supply chain, providing insights on raw material costs, production trends, accounting KPIs, and sales metrics.

But of course, Ekos is just one part of the puzzle. With greater connectivity comes greater visibility. Ekos sees a few key areas of opportunity for breweries who want to set themselves apart from the competition and find ways to grow their businesses, despite the current challenges. Ekos Order Hub, for example, is an online portal that is directly connected to Ekos, so when customers place an order, it automatically creates a sales order in Ekos and depletes inventory in real-time. It also streamlines the approval of sales orders and keeps all communication about orders in a centralized location.

But that’s just one example. Read more about how technology is helping craft breweries in 2022, and be sure to stop by booth #2525 at the Craft Brewers Conference to connect with the Ekos team and get a demo.

Flottweg shows off AC1200 decanter centrifuge (available for purchase!)

Flotwegg | #2645

Flottweg Separation Technology’s AC1200, a decanter centrifuge helping craft brewers boost yields, will be on display and for sale at the Craft Brewers Conference. Flottweg decanter centrifuges are used to process the hop sludge from the tank bottoms that would otherwise be dumped. Decanter centrifuges are capable of separating liquid from very heavy solids concentrations. The beer is recovered from the solids and returned to the tank while the dewatered waste is sent to a container for disposal. The process removes large amounts of solids from the waste water effluent as well as taking a considerable load off of the downstream equipment while increasing the overall yield of each fermenter.

Festo showcasing slew of automated solutions for brewhouses and packaging lines

Festo | #2953

Festo has a ton of automated solutions to tell you about. Festo control systems provide batch-to-batch consistency and precise management of ingredients for low waste. Automated valves control flow and pressure, and its I/O systems reduce the number of wires and tubes required for easier trouble shooting. IP65, IP67, and IP69 rated components do not require control cabinets, which saves space and lowers cost. Festo packaging line solutions deliver precision filling and package handling, as well as high-speed automated inspection capabilities. If you need help choosing the right level of solution for your brewery, the Festo Quick Search Plus Application tool identifies the precise components for the application.

Order a complete brewery from Custom Metalcraft

Custom Metalcraft | #3459

Custom Metalcraft offers a ton of technical expertise, innovative engineering and manufacturing resources to deliver complete brewing systems. Its engineering department features mechanical, electrical, civil and brewing systems engineers ready to develop your specific requirements into functional solutions. Complete breweries including:

- Brewhouses up to 100 barrels

- Cellar tanks up to 400 barrels

- Automation packages – standard or custom

- Tote/IBC Tanks – standard or custom

A 7-barrel serving tank will be on display.

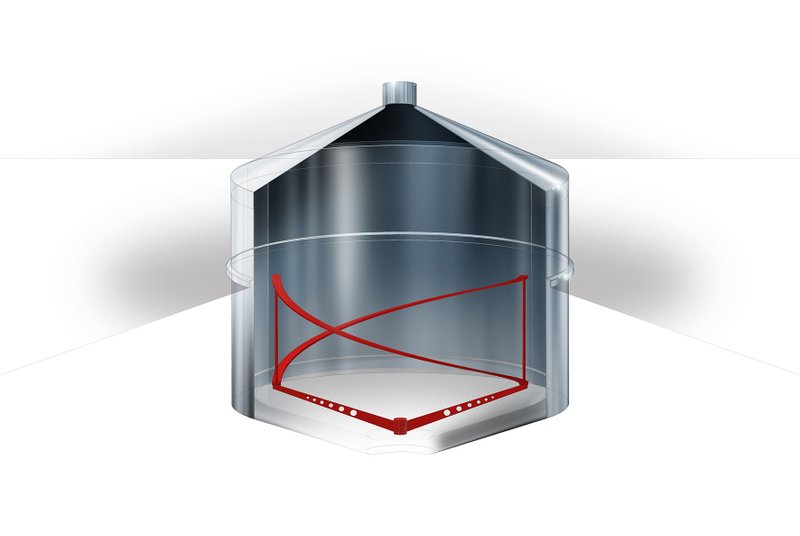

ZIEMANN HOLVRIEKA focuses on mashing and tank construction

ZIEMANN HOLVRIEKA | #5705

The focus of ZIEMANN at the CBC will be on mashing and tank construction, presenting the mash agitator COLIBRI by ZIEMANN. This mash agitator primarily is a combination of the advantages of several mixer geometries. A perforated plate above the bottom heating zones ensures the required flow and mixing. At the end of the perforated plate, two solid bearers bypass the shell heating zone like an anchor agitator. The bearers have a spiral, which passes through the mash with its wing-like profiles. The homogenizing effect of the COLIBRI is further intensified by an inclined transverse bracing. Overall, the COLIBRI ensures the requested turbulences at the boundary layers of all heating zones as well as the horizontal and vertical homogenization of temperature and concentration.

DME Process Systems Ltd, Canada, which belongs to the same group of companies, also will be presenting itself at the booth, rounding off the portfolio with standard solutions also for small brew sizes.

Leave a Reply

You must be logged in to post a comment.