Nutritional fermentation requirements for seltzers are unique from beer. Like any product, brewers need to understand their base media. In seltzer’s case, that means sugar substrates like sucrose and dextrose — which are extremely nutrient deprived ingredients. For successful fermentation, yeast needs to greedily feed to be happy, healthy and productive, so a complex blend of nutrients will need to be added. These are powders and tablets (full of nitrogen, proteins, peptides and more) added at the end of the boil or in the whirlpool right at the start of fermentation. Here’s a tip: Don’t add nutrients to a seltzer’s sugar boil too early in the process. Too much heat could negate the benefits of this important nourishment. Here’s another tip:

“We recommend mixing the nutrients with water and adding the nutrient mixture into the fermenter at the start of fermentation, prior to inoculation with yeast,” said Nate Siats, director of East Coast/Midwest sales-beverage and business development manager at Gusmer. “This ensures the nutrients don’t clump up together and that there is an abundant supply of nutrients for the yeast to thrive and complete fermentation at high stress conditions. Depending on process capabilities, some customers may choose to add nutrients into the kettle or into the whirlpool. This is perfectly acceptable. This ensures proper mixing and ease of preparation in getting the nutrients into the solution and into the fermenter.”

Gusmer is an expert supplier of processing aids and fermentation equipment (and a bunch of other equipment and supplies). Gusmer’s MicroElements Brewing Nutrient Tablets are a diverse blend of vitamins, minerals, polypeptides, and amino acids that are essential precursors required to build yeast biomass in beer brewing. Gusmer also now offers a MicroElements Hard Seltzer HG, which is a powder blend of complex fermentation nutrients formulated specifically for high gravity seltzer fermentations.

“MicroElements Hard Seltzer HG is a new product addition to Gusmer’s MicroElements product line,” explained Jasmin Sahota, technical applications manager — beverage at Gusmer. “The nutritional and fermentation needs for brewing are different from seltzer. For instance, MicroElements Brewing Nutrient Tablets contain organic nitrogen, amino acids, sterols, Zinc, among other key vitamins and minerals. The tablets are recommended to use at the last 15 minutes of boil in the kettle. MicroElements Hard Seltzer HG is a powder blend of complex fermentation nutrients optimized for high gravity seltzer fermentations. It is composed of organic and inorganic nitrogen, vitamins, trace minerals, amino acids, sterols, proteins and peptides. The combination of these nutrients are important in overall yeast health, metabolism, ensuring good fermentation kinetics and optimized production of neutral flavor and aroma over off-flavor compounds in seltzers.”

Unhappy yeast lead to subpar products. Nutrient deficient fermentations lead to poor yeast health, limited or stuck fermentations, low alcohol yields and product off-flavors. Sahota notes that Gusmer was focused on those critical parameters in developing a nutrient blend specific to hard seltzer with a goal of achieving neutral flavor and aroma, fast fermentation times and high alcohol yields. As mentioned, this product comes in powder form.

“Powder blends are more cost effective to produce and make it easy for the user to weigh out specific quantities needed for their recipe,” said Sahota. “Our dissolvable tablets have been optimized for set volumes and are designed to be an ease-of-use solution for our customers to count out the number of tablets needed without needing to weigh out for their recipe and simply add to the kettle towards the end of boil.”

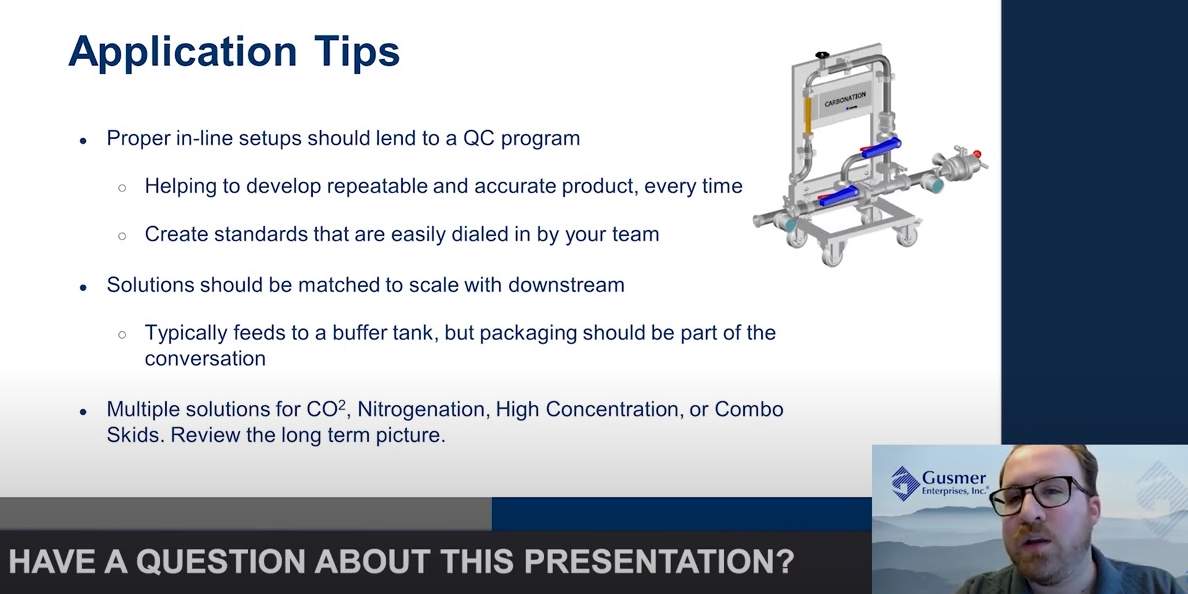

Gusmer offers a wide range of products and process equipment to ensure high-quality seltzer can be produced. Process products include: Yeast offerings from Renaissance and Chr. Hansen; enzymes from IFF; fining agents from Nalco, PQ and BASF; Gusmer’s own line of filtration products ranging from sheets, lenticular stocks and loose cellulose fiber, including carbon media in both sheet and lenticular stack form. Gusmer process equipment includes a full line of high-end systems from Denwel in categories like inline carbonation and nitrogenation, inline dosing and blending and flash pasteurization. The company also has some nice packaging, canning and kegging equipment available via Malek.

“The hard seltzer space took the brewing market by storm and over the past few years grew at an incredible pace,” said Siats. “Now that the market has evened out and matured a bit, there are just a few top producers that account for the bulk of the hard seltzer we see on the market today. Product differentiation allows a producer to compete with these top brands, and it all starts with a clean and neutral base up front. The cleaner your base is up front, the less downstream processing you need to do. We have spent a considerable amount of time running trials with various nutrient combinations, yeast strains and even competitive products to come to our final formulation which is MicroElements Hard Seltzer HG — to offer hard seltzer producers a nutrient that can be used to achieve high alcohol fermentations in a clean and neutral way.”

For more info, click right here.

Leave a Reply

You must be logged in to post a comment.