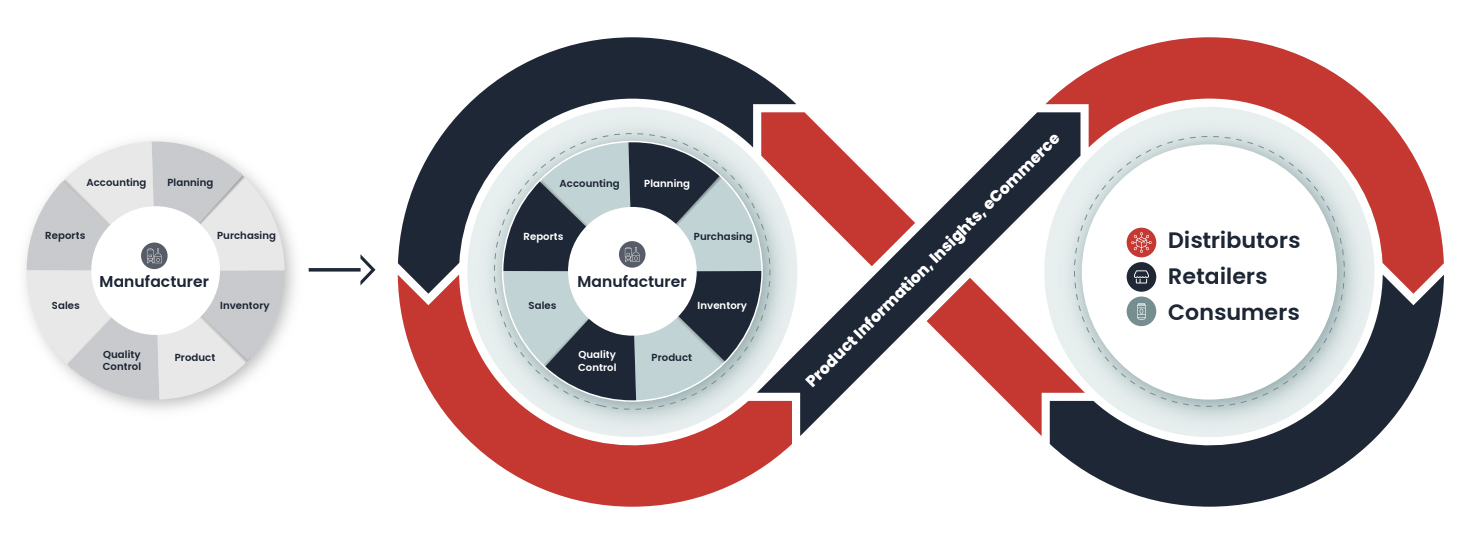

Plagued with new challenges like shortage of labor, scarcity of packaging materials, rapidly changing consumer preferences, increased innovation beyond beer, BevAlc manufacturers’ businesses are quickly changing along with the rest of the three-tier system. The past two years have highlighted the need to streamline and automate operations within manufacturing facilities. More importantly, connecting, communicating, and sharing data and insights across the three tiers of the supply chain now underpin new, more agile manufacturing best practices.

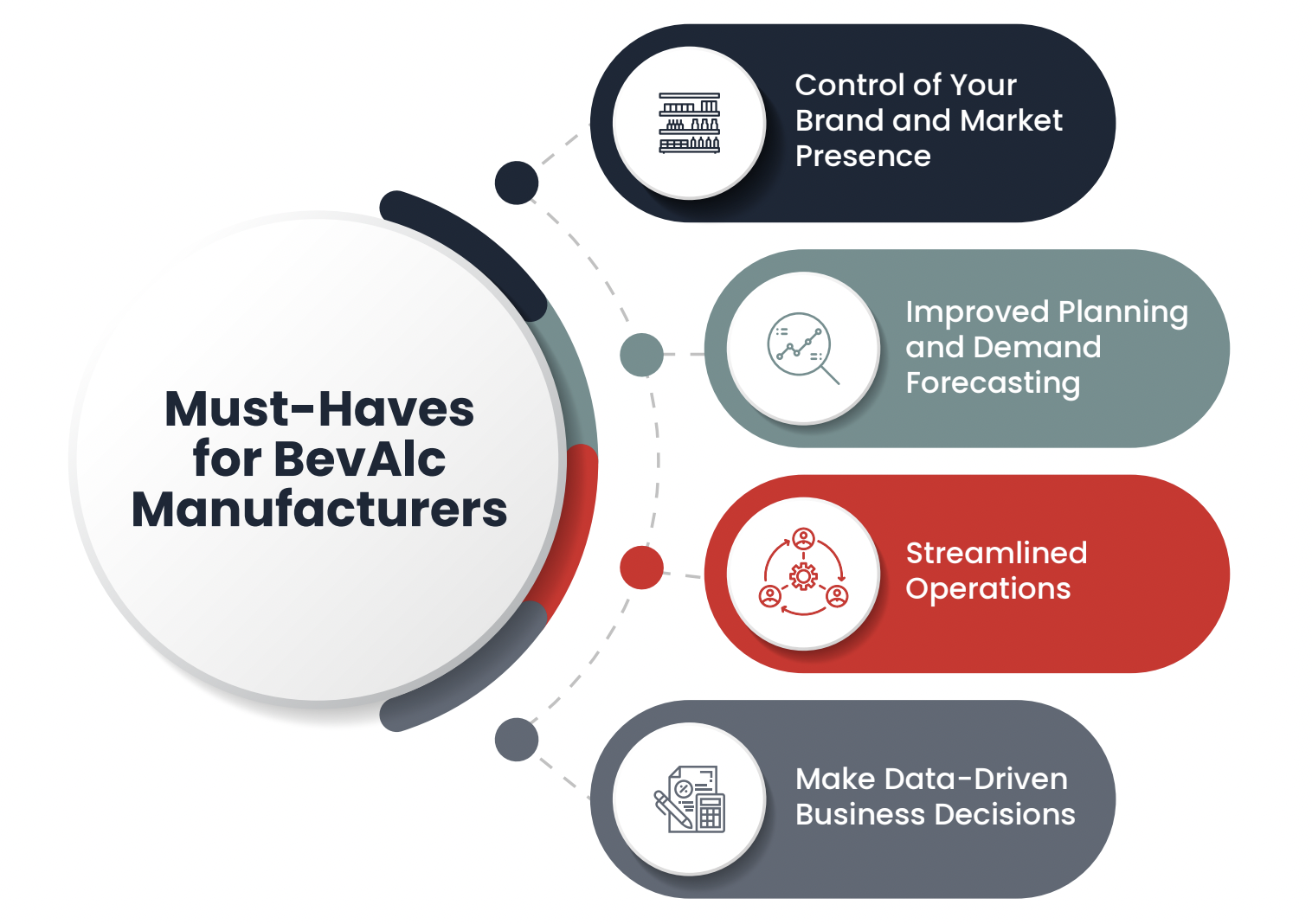

What manufacturers may have deemed ‘nice-to-haves’ are becoming ‘must-haves’ to run competitive, successful businesses. The good news is the ‘must-haves’ have also become ‘can-haves’ for manufacturers of all sizes thanks to cloud-based ERP (Enterprise Resource Planning) technology innovation, inherently built to solve challenges within and outside the four walls of a business. Let’s take a closer look at four new emerging best practices.

Product Information Management (PIM) tools to control brand and market presence at all supply chain touchpoints

Representing a brand consistently throughout the supply chain has a significant influence on a manufacturer’s success in the market. The product description, ABV, UPC codes, package sizes, images, ads, sell sheets, and more can all inform a downstream buying decision. Missing, inaccurate, delayed, or inconsistent information anywhere along the supply chain results in lost opportunities to advertise, receive orders, fulfill orders, and receive payments.

Product Information Management (PIM) tools automatically handle the mapping of product information, enabling information to flow through the three-tier system via an expansive, interconnected eCommerce network.

As a result, manufacturers gain unprecedented control over individual brands and market presence. E-shelf product placements, digital ads within a connected network, and streamlined entry of new products enable manufacturers to effortlessly expand their online reach down the supply chain. Moreover, PIM tools can connect to an open ecosystem of partners by showcasing product data through consumer-facing eCommerce ordering platforms and solutions for the retail and distribution tiers.

Transparent retail inventory data to improve planning and demand forecasting

Transparency in distributor-to-retail sales and retail inventory data creates a feedback loop up and down the supply chain to most effectively meet consumer demand through three-tiered collaboration. This allows manufacturers to move away from traditional straight-line forecasting methods primarily based on the previous year’s distributor-to-retail sales. Historical methods are unreliable in fast-changing markets because of inventory blind spots at the retail level.

Insight into retail inventory provides a more complete picture of how products move at the consumer level. Deeper vision into product performance enables manufacturers to strategically analyze this data against time/season, geography, market, and other parameters. Transparency of retail inventory data powers a new way of demand planning that helps manufacturers adapt to rapid market shifts.

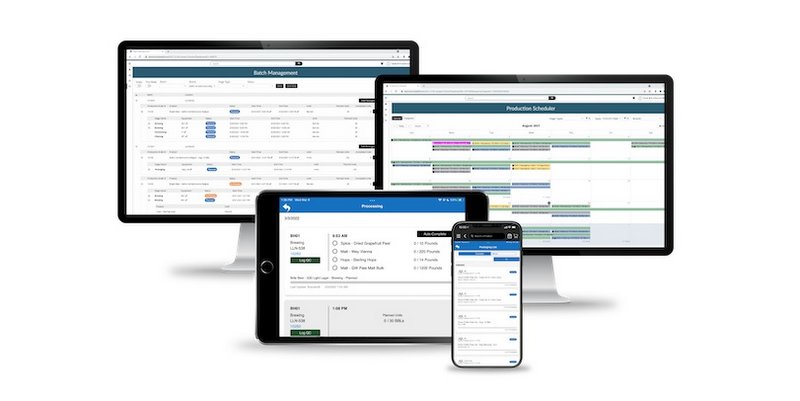

Systematizing SOPs to ensure quality amid labor challenges

With increased employee turnover, manufacturers need a quick, easy, and intuitive way to onboard new hires without compromising product quality as the workforce turns over. What a consumer might hail as the “best beer in the world” or say is worthy of “my go-to” status may be “just OK” the next week because it tastes differently. In fact, it could be different enough that the consumer will revert to drinking something else, ultimately impacting the company’s revenue.

Streamlining communication of step-by-step procedures through handheld mobile devices eliminates the need for new employees to reference a whiteboard on the other side of the production facility or dig through a binder of old recipes. Manufacturers no longer need to worry about delays, inconsistencies, or errors as a result of changing a page or a whiteboard to reflect adjustments. Furthermore, it helps neutralize the challenges around translation of information from person to person, batch to batch, and brewmaster to production floor worker.

Systematizing Standard Operating Procedures (SOPs) enables all employees to deliver revenue-driving results, regardless of tenure in the company. Advancements in technology enable production teams to visualize preexisting SOPs and enter new data into mobile handheld devices at any point throughout the production process. The system also communicates SOPs by taking measurements, analyzing data, providing alerts when measurements are outside specifications, and, in some instances, recommending remedies depending on the procedural variance. The end result is a better use of limited people resources and consistent product quality for consumers.

Data-driven forecasts on product cost and margins

It’s difficult for manufacturers to fully conceptualize potential profit when piloting a new product. Manufacturers often have costs for raw materials and packaging, but no way to comprehensively calculate labor costs. When manufacturers choose to introduce a product at a competitive price but can’t accurately forecast labor costs, loss of money is an unfortunately common result.

When a system does the math to help manufacturers calculate cost and margin, it becomes easy to make data-driven decisions without the need for an accounting or finance degree. More importantly, with the system providing data transparency and insights across all three tiers, manufacturers can more confidently set pricing, drive revenue, and meet target margins.

Modern, connected ERP systems have enabled the ‘must-haves’ to become ‘can-haves’ for all BevAlc manufacturers through retail insights, sharing of product information, and eCommerce, ultimately resulting in exponentially stronger industry collaboration to meet consumer demand.

Many small-to-large, fast-growing manufacturers are now able to buck the misconception that only the giants of beverage manufacturing have the ability, resources, and money to support the automation and systematization of SOPs. In fact, it’s more than just leveling the playing field. Manufacturers gain a competitive edge by being able to share information, strengthen business with partners downstream, control their brand across the supply chain, and better forecast demand. In the end, the consumer reaps the benefits– more choices and higher quality products available to them whenever, wherever, and however they want to buy.

—-

Jonathan O’Neil is CEO of Encompass, which launched Orchestra Cloud as its latest move to digitally connect the beverage supply chain.

Leave a Reply

You must be logged in to post a comment.