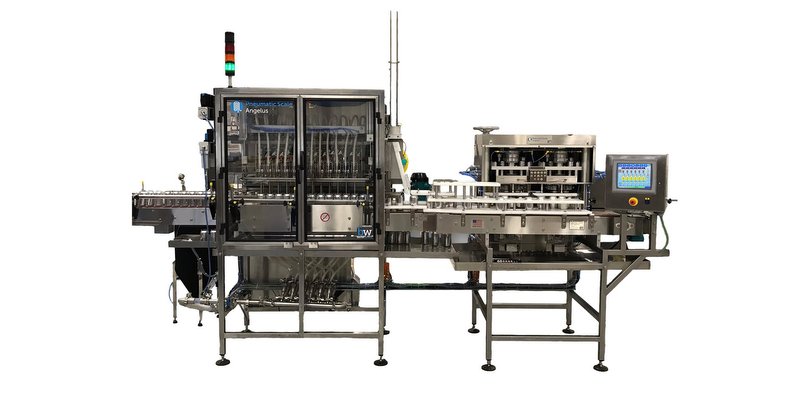

Spring is here, and summer is nearly upon us. That means the reemergence of fizzy and fun beverage alcohol from seltzers to RTDs is also upon us. Both trend hard in the warm, outdoorsy seasons. To help craft beverage producers meet the growing demand for heavily carbonated and canned beverage alcohol, Pneumatic Scale Angelus produces its CB50C counter-pressure integrated canning line — perfect for hard seltzers, RTDs (ready to drink cocktails), sparkling wines and higher-carbonation beers (think brutes, saisons, tripels and onward).

Employing six individual filling heads and a single-head seamer, the CB50C uses isobarometric counter-pressure technology, coupled with proprietary magnetic flowmeters, to deliver a system capable of one-milliliter filling precision. The line is rated for continuous operation at speeds up to 50 cans per minute (cpm). You can see the rig in the video above, and you’ll be able to see the CB50C in person at CBC — the annual Craft Brewers Conference and BrewExpo America in Denver in September. From the press release:

“Our CB50C system uses true isobarometric filling technology,” said Mike Davis, Product Line Leader for Can Filling for PSA. “Because our fill tank is positioned above the fill heads, the product is gravity-fed, versus being pumped or forced upward. This means the product experiences little to none of the agitation that causes the unwanted reductions in carbonation levels seen with other filling methods.”

Precision fills keep that CO2 intact, creating beverages with an excess of 2.7 volumes of carbon dioxide. In isobarometric filling, the can being filled and the product going into the can are at equal pressure, maintaining carbonation solubility throughout the filling process. Pneumatic Scale Angelus actually introduced the CB50C counter-pressure system to the market last summer, and several craft brewers have begun running full production with the line.

“COVID-19 and the taproom closures that resulted from it created an extremely challenging environment for the craft beverage industry,” said Adam Brandt, Vice President of Sales for PSA. “But, for enterprising brewers, it also afforded them the opportunity to expand their portfolios into markets they might not otherwise have ventured into right away. There are so many opportunities to expand, and we’re excited to be able to partner with them and help them realize growth in these new areas.”

Some other specs

The CB50C has many of the same features as PSA’s well-known CB50F and CB100F open-air canning systems:

- Magnetic flowmeter technology helps brewers get a perfect fill with little waste, and an under-cover gas flush system helps keep dissolved oxygen levels low.

- The company’s high-speed, industry-leading double-seaming technology keeps cans sealed tight, extending critical shelf life.

- The integrated system is optimized for sleek and standard can bodies and is designed for quick-change adjustments and easy changeovers for various can heights and body diameters, with no valve change required.

- Operating the system is simplified with a compact footprint and an intuitive HMI that allows for individual fill head volume adjustments.

Leave a Reply

You must be logged in to post a comment.