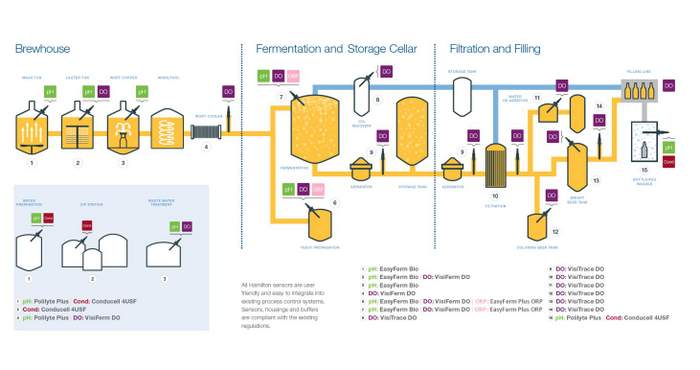

When it comes to improving your quality control processes, or just the overall awesomeness of your final product, inline instrumentation that measures and reports on your pH and conductivity levels often provides the best bang for your buck. One reason is how many areas these inline sensors can be utilized.

“The salts and minerals that are in the brewing water have a massive effect on how the enzymes work in your mashing chemistry,” says Justin Juengel, technical sales rep with Gusmer, during a webinar last week. “They have a big role to play in hop chemistry. They drive how quickly and how thoroughly your fermentations will occur as well as what esters and other compounds are formed during fermentation. They affect chill haze and your CO2 saturation. And all of that definitely has impacts on the bottom line, whether it’s raw material costs or capacity or beer loss.”

Basics: Conductivity the measurement of the ions in a solution. That property makes it a fantastic way to detect interfaces between two disparate aqueous solutions. pH is a measure of how acidic or basic an aqueous solution is on a 0 to 14 scale.

The Gusmer webinar explained the benefits of in-line instrumentation while also hyping the virtues of Hamilton sensors (Gusmer is the sole distributor for Hamilton sensors and products in North America and Canada). The Hamilton Company has been manufacturing precision measurement devices for over 60 years, and its partnership with Gusmer dates back to 2014.

Why inline? For both, inline instrument allows you to see these levels in real-time and discover trends. If you’re doing this analysis in the laboratory, you’ll have take into account temperature corrections and other factors.

“It eliminates the labor of doing the lab analysis or having your brewer run out with a pH strip to measure it every brew, and it gives you the ability to capture the data and do some analytics with it,” Juengel says.

Common inline uses are process monitoring, control of dosing systems and determination of the interface between two liquids. Here are some practical applications Juengel said to consider on the webinar:

Sour beer

“I think those of us who drink sour beer on occasion get our hopes set high that we’re gonna have this fantastic sour beer from this great brewery, and you take a swig and it’s automatically burning holes in our stomach,” Juengel says (as we nod our heads). “You know darn well that’s not the intention of the brewer and that something in their process got out of whack. Use of an inline pH probe allows you to control that process.”

Whether you’re doing kettle souring or a lactic fermentation or adding lactic acid, in-line pH testing will allow you to keep control.

“As a sour beer fan, I highly encourage you, for the for the love of my ulcers, please buy a pH probe. They’re cheap.”

Process control and microbiological monitoring

Juengel worked for a big brewing company for quite a while, and he says they had pH probes in all of their transfer lines as a fail-safe to avoid pH drift. So, say your mash is typically in the 5.3 range, and all of a sudden you have a mash transfer into the fermenter that’s at 4.9 or a 5. This will tell you something is wrong before the mistake gets too far down the line to correct.

“While it sounds like it might be a solution just for the for the big guys, in small breweries, I really like to encourage folks that if you’ve got a transfer pump that you use, build a little pipe spool with a pH probe — make sure you protect it, so it doesn’t get whacked around too much — and put it at the inlet or outlet of your pump,” he says. “When you hook your hose up for every transfer, you know you’ll have a live pH reading, and it can tell you a lot of what’s going on in your brewing process.”

CIP process

Caustic / acid has to have a certain strength in order for it to be effective, so if you install a conductivity probe in your tanks, batch to batch, you can make sure you’re making the exact conductivity you need to get a proper cleaning.

“The other avenue is if you’re recovering your caustic, if you install a connectivity probe on the return line, it’ll let you detect when you hit the interface between water and caustic,” Juengel says. “This keeps you from diluting the tank and allows you to reuse the caustic in the most judicious fashion.”

But another key here is process loss prevention. An inch and a half brewer hose that’s 100 feet long holds just under 10 gallons of beer. Now, picture your process.

“If you’re using long hoses from the filter beer tank to the bottling equipment … and you take into account all of the different transfers that you do throughout the day and add up all that volume, pretty quickly you can justify on an ROI basis the installation of a conductivity probe.” Juengel says. “It’ll allow you to push that beer out of the out of the line with water and detect that interface.”

Wastewater

Wastewater is one application for both pH and conductivity that breweries might not consider enough, especially if you’re small and in a municipality that’s just not paying attention yet.

“As you get bigger, you become more and more on the radar of the local municipalities,” Juengel noted, “and in my past life I worked with a brewery in Virginia that was so strict, if some of these parameters got out of whack, the city could shut the pipe off at any point they wanted to.”

At a minimum, as you grow, installing a pH probe and a conductivity probe on your wastewater discharge line will let you monitor all of this. It also “gives you a nice summation of what you’re sending to the city, so if they accuse you of sending a high BOD load to the city, you can pull up your records and say ‘hey, it wasn’t me.’”

Brewing water makeup

“It always puzzles me when I go into an artisanal brewery that’s really proud of making their beer true to style, and you see a city water line going to their brewing water tank without treatment,” Juengel says, and it’s a great point. Brewing water is 95 percent of the product, and city water is a wild variable. If you’ve ever looked at a municipal water report, ground water-sourced city water is constantly in fluctuation, sometimes day to day as the temperature changes.

But with a couple of well-placed conductivity probes you can stay on top of this in real-time.

“All it really takes is an activated carbon filter solution,” Juengel says. “We at Gusmer have a couple of options that are cost effective, and you can go all the way up to some of the big expensive systems, but the activated carbon is going to strip your water basically down to elemental water. It’s going to take a lot of those salts and minerals out. … It won’t tell you specifics of what your sodium level is and what your magnesium level is, but it’ll tell you at high level what your salt is, and the conductivity probe downstream of the carbon filter will tell you how good of a job your carbon filter is doing. Ideally you should see a big delta between those two probes, and if you don’t, it’s a good indication of when to change out your carbon filter.

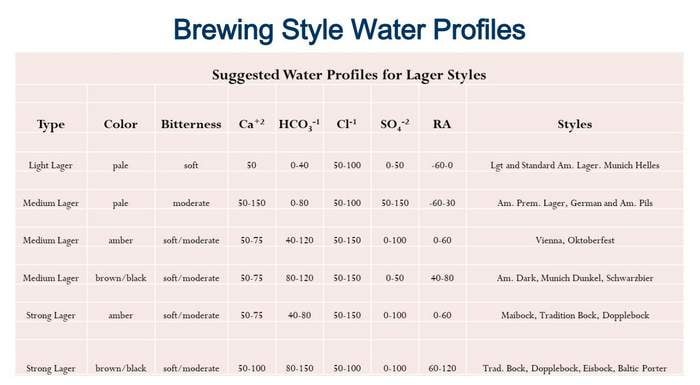

Consider this example of the variables of just within lager styles.

At a minimum Juengel and CBB fully recommend that all brewers do at least this step, either followed by an ingredient injection system to add different acids or salt slurries to adjust on the fly or just doing such additions by hand. Either way, in-line sensors will let you know when you hit your targets for the style.

“For a super basic system you can get some pretty good results for let’s say under $10,000.”

Definitely check out the full webinar for more detailed info on the science behind all of this and some of Hamilton’s offerings.

Leave a Reply

You must be logged in to post a comment.