Craft brewers derive a large part of our revenue and profits from an onsite taproom operation, catering to large crowds of people happily enjoying a variety of different beers crafted in small batches. Shutdowns, capacity limitations and safety concerns for both customers and employees crippled that model — causing an existential threat to many craft breweries. And, like many other hospitality-industry entrepreneurs, brewers responded by being creative. Many of us shifted to making beer to go, in traditional growlers, bottles, crowlers, and a lot of cans.

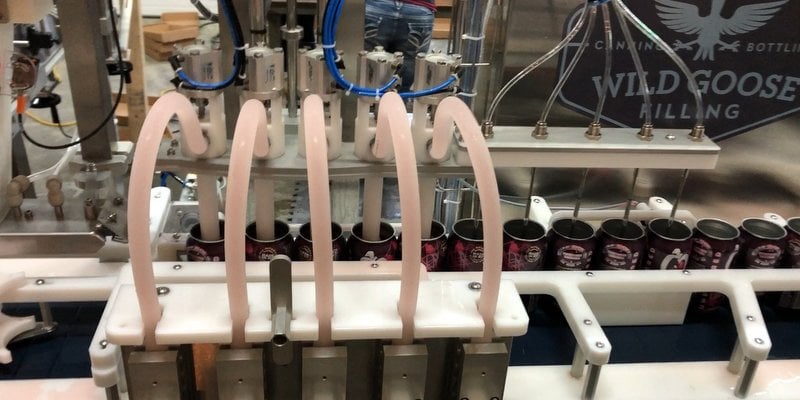

Craft beer had already been moving rapidly from glass to aluminum. As early as 2019, Brewer’s Association analysis had shown an increasing preference for cans, with cans going from less than 20% of the total in 2015 to about 47% by 2019. Consumer preference, cost, ease of recycling, retailer preference, and numerous other factors were driving this shift.

When 2020 hit, that shift went into overdrive, and the percentage of cans soared to over 55% in mid-2020. The rise in can usage combined with supplier plants being affected by the pandemic, uncertainty around global supplies, tariffs, and other factors, caused a predictable result: a can supply shortage.

For some breweries, especially those with established supplier relationships, the shortage has been manageable, just creating a stress-inducing last-minute supply instead of the more predictable supply.

But for smaller breweries, especially those who just started canning or don’t have high enough volume to warrant the priority attention of the suppliers, it has been more of an existential threat.

For these smaller breweries, the can shortage is a constant battle of chasing supplies, dealing with sudden price increases, not being able to get beer out of tanks, and of course, missing out on sales.

At Wolf’s Ridge Brewing, we’ve been fortunate to have a long-term partnership with our packaging supplier, and they’ve been very helpful in getting cans to us. Even so, we’ve seen delays and price increases, along with concerns about cans coming in with different profiles, which has proven to cause problems with existing canning equipment.

Many smaller breweries, us included, have pivoted to re-labeling over “extra” cans that were ordered and labeled for different batches of beer earlier on, but were never filled as a result of the beer not selling as well as projected. Most recently, we re-wrapped cans from a batch called “Leisurely” to can our newest low-calorie IPA Pup.

Breweries will purchase pre-painted or wrapped cans, and if there are any excess after a packaging run, these were either getting scrapped or saved until the next run, which could often be a year away. Despite an increase in packaged beer sales in 2020, predicting sales of a specific brand can still be as difficult as ever, which can result in a surplus of pre-printed cans for a seasonal brand that a brewery can no longer sell after a certain date. Instead, these can get re-labeled, which helps to reduce the impact of the shortage.

At Wolf’s Ridge, we’ve seen an unprecedented shift in preference for “new” and “small batch” beers packaged in cans.

While this is something we and many others have been forced to lean into in 2020, it nevertheless causes challenges with forecasting demand for larger batches and brands meant to stay on the shelves for longer periods of time.

The shortage also hasn’t been limited to just cans — bottle supplies have been affected as well. In the case of bottles, it’s been more due to plant shutdowns than anything else, but the peak of that shortage came just as many breweries were ramping up seasonal production for the holidays. For those beers, a shortage or delay can cause a significant loss of revenue, at a time when it can least be afforded.

While there is, according to one supplier we spoke to, an estimated 5.5 billion can shortage in the U.S. this year, the aluminum can industry has been responding by beginning to build new capacity. Though that capacity can take a long time to get online, there is hope! In addition, as draft returns, it’ll take some of the pressure off many of the smaller breweries.

In the meantime, when you see packaged beer in the marketplace which looks a little different than normal – maybe a different color bottle, or cans that have been re-wrapped or with a label covering the printed design beneath, know that the brewery is merely using every tool in the box to survive right now, and that the change is only temporary. Craft brewers will continue to do what we do best — innovate and create the most interesting and delightful brews we know how to, and hopefully we will be stronger on the other side.

Alan Szuter is co-founder of Wolf’s Ridge Brewing, and Chris Davison, head brewer at Wolf’s Ridge Brewing

Leave a Reply

You must be logged in to post a comment.