In February, Craft Brewing Business will be focusing on craft brewery quality assurance / quality control — not just in terms of the beers that you brew but in your packaging processes, cleanliness, safety best practices and anything else successful breweries would be wise to shore up. To get things started, here is a roundup of some of the best QA/QC tagged articles sitting in the CBB archives. If you have any QA/QC news items or tidbits to pass along this month, feel free to send them to [email protected].

A Day in the Craft Brewery Lab, part 3: Sensory Panel Setup, Tasting Tips and the Triangle Test

A sensory panel can help you identify off flavors, aid in troubleshooting problems in the brewery, and make sure you’re producing beers that are true to brand. It’s an inexpensive way to evaluate your beers before releasing them into the marketplace and an essential part of any quality control program. Your pilsner can be spot on for alcohol, bitterness, color, pH, free from any type of infection, yet have a slight cooked corn flavor that wasn’t in the last batch. Or your Belgian pale ale could be lacking that spicy black pepper note your customers have come to expect.

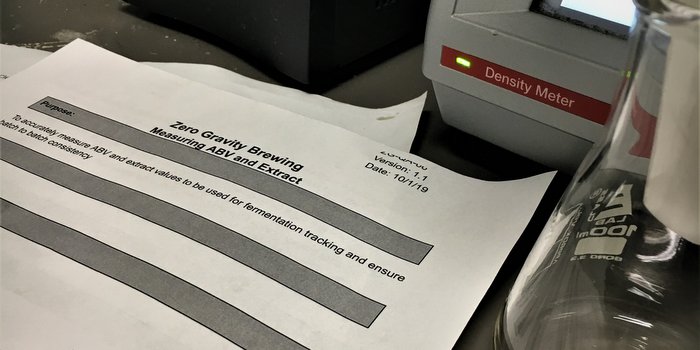

Watch: How to calibrate and use hydrometers to measure beer or wort density

Hydrometers can be used to accurately measure sugars, specific gravity and the density of samples. It’s that large thermometer-looking thing that floats higher in a heavy liquid and lower in a lighter liquid. Just make sure you choose a hydrometer that covers the density range appropriate for the liquid you’re measuring.

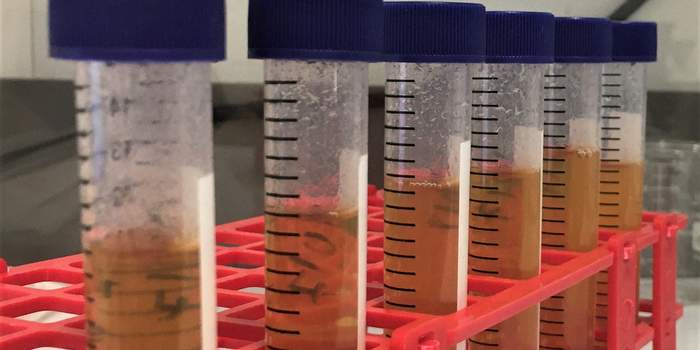

Beer spoilage prevention: What is saccharomyces cerevisiae var. diastaticus and why should you care?

Diastaticus is a variant of brewers yeast which has diastatic properties, or the ability to break down starch into simple sugars which can then be fermented. Because diastaticus can ferment sugar that is usually unfermentable, it poses a severe beer spoilage risk.

How craft breweries can use color-coding to improve safety, sanitation

With the passage of the Food Safety Modernization Act and the increase of standards in brewery inspections, brewers are looking to tighten up their sanitation and safety measures. To do so, many are incorporating color-coding plans in their facilities.

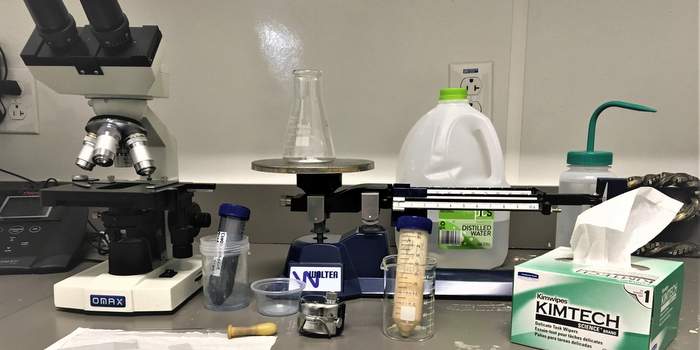

A day in the craft brewery lab, part 5: In-depth guide for cell counting

In many breweries, the lab is responsible for counting yeast cells and communicating the amount of yeast needed to pitch each batch of beer. Other breweries you’ll find this falls on the brewers or cellar workers. It’s great to have a variety of people who are trained on it since people like to take a vacation every now and then.

Beer qualities vs. beer quality: How to improve your brewery’s QA culture

The No. 1 reason consumers gravitate toward craft beer is because it is local and independent, but a big part of a local good’s appeal is the inherent attribute of quality. No one buys local expecting a shoddily created generic commercial product. Hitting that high-quality bar requires an organizational culture that focuses on it.

Cleaning is key: Proper hygiene is the benchmark for quality and consistency in beer

The number of craft brewers in America is now more than 7,000. With so many new establishments on the rise and amateurs aiming to become master brewers, brewery owners and managers need to understand the essential requirements of cleaning. Without a proper cleaning program in place from day one, hygiene issues, quality lapses and customer complaints can negatively impact your brand before it becomes big.

Five tips to help improve brewery quality assurance

When it comes to any area of the food or beverage industry, quality assurance should always remain a top priority. Breweries are one particular member of the industry that needs to work on the quality assurance of their product continually. This fact is especially true for large-scale brewery operations where products are shipped out to different markets for consumers. Here are some tips to help brewery operations improve their quality assurance levels.

Leave a Reply

You must be logged in to post a comment.