You’re probably thinking that just because this is my first week back from vacation that I’m only posting this best clips episode story to get out of real work. Nonsense. This recap of awesome equipment is aimed at helping you improve operations in 2020. The year is still fresh, new and optimistic. Opportunity is just over the horizon, and what better catalyst for future success than to improve your manufacturing operations.

Invest in multipurpose vessels. Re-engineer your dry hopping methods. Upgrade that old pipe and hosing. Hell, buy a new beer serving truck (the Isuzu one below is insane). Even if you’re not in a position to purchase new equipment right now, it’s always good to understand what’s new on the market. Because many of these new products can make you more efficient, and that can be the difference-maker in today’s ultracompetitive craft beer marketplace.

Inside the dry hopping efficiency of GEA’s HOPSTAR Dry

The factors in hops that make or break a beer are lupulin as well as the hop resins (alpha and beta acids) and hop oils it contains. During the boil, the alpha acids transform into iso-alpha acids, which bring out the beer’s bitterness and are used as a gauge of its International Bitterness Units (IBUs). But hops can do so much more. Very special aromas come from the hop oils extracted from aroma hop varieties. Hop oils are volatile and are lost at excessively high temperatures. That is why aroma hops are not added to the beer wort during boiling. Instead, the hop oils are added during a second step, namely dry hopping. This process of dry hopping, sometimes referred to as “cold hopping,” is mainly associated with craft and specialty beers.

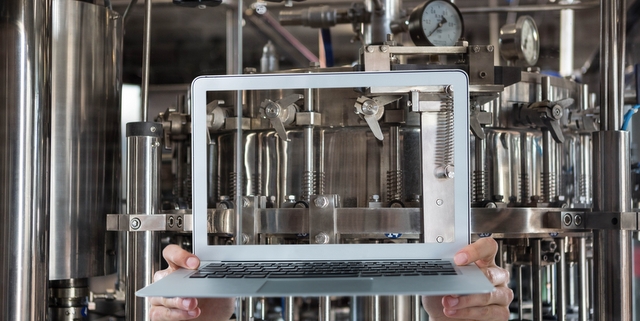

THIELMANN’s multi-purpose Aseptic Container brewing vessels

We’ve been covering a lot of boss multi-use brewing equipment in recent articles, and here’s another clever and flexible option from THIELMANN. These Aseptic Containers are built for breweries and wineries that are looking for 1) a high-quality stainless-steel product that’s easy to clean and 2) the ability to tackle multiple beverage applications with one tank. Fermentation. Carbonation. Yeast propagation. Brite tank. Storage and serving. These THIELMANN Aseptic Containers can do it all.

BrewSavor’s new Kink Resistant Brewery Hose

The BrewSavor line of products from tubing and hose manufacturer NewAge Industries now includes kink resistant, stainless steel wire reinforced hose. It joins BrewSavor’s crush resistant monofilament reinforced hose as another option for the demanding fluid flow applications in craft breweries and other food and beverage facilities. This choice of hose allows brewers to select the best product for their particular environment.

Twin Monkeys’ Mancos nano-canning solution is a cool, low-cost, tabletop, automatic canning line that takes lots of can sizes

As a craft brewery, what’s your first step into packaging? Kegs? Mobile canning services? Perhaps a smaller footprint, entry-level automated canning line? Let us introduce you to Twin Monkeys’ Mancos. Operating at an output of 10 cans per minute (for 12-oz vessels), the Mancos can do up to 600 cans per hour or 25 cases. Get a feel for the unit’s crazy small size (40 in. long by 33 in diameter by 30 in. in height) and purple majesty in the video above. Weighing only 250 lbs and constructed of 304 stainless steel and anodized aluminum, the Mancos can handle a variety of can sizes too, including Crowlers (TM), sleek, slim and, of course, standard cans.

Christian Gresser vessels, made in Germany’s beer Nirvana of Bavaria.

The Gusmer brand is one of the strongest when it comes to suppliers of processing aids and fermentation equipment in a variety of beverage industries — juice, wine, spirits and beer. The company has also become a one-stop shop for cool beer equipment as it continues to partner with a variety of international brands in a distributor role — names like Bucher-Unipektin, Ponndorf, Hamilton, PQ Corp., Aber and onward. Well, Gusmer has just launched a new alliance that will most definitely interest craft brewers.

Ska Fabricating releases new Half Pint OD mobile depalletizer

In its never-ending drive to pioneer the industry’s leading packaging line solutions, Ska Fabricating is debuting the new and improved “Half Pint OD” mobile depalletizer. The OD (Orbital Discharge) features the same lightweight, low-footprint spirit of the original Half Pint with a new patent-pending rotary table design. This machine’s 30-in. wheel is the first of its kind, allowing for more accumulation, higher line speeds, a smaller footprint and a better drop angle for the rinse cage. The wheel can run clockwise or counter-clockwise, making it possible to install two discharges for different container sizes with little to no changeover.

Paul Mueller Co.’s sweet-looking beer serving tanks

Enter Paul Mueller Co. serving beer tanks. These steely serving tanks utilize a self-cooling, bag-in-tank system that can be used directly in a taproom. These tanks allow breweries to transfer the carbonated beer straight from a brite beer tank with the ability to serve in just a few hours. No need for kegs in the brewery. This allows a brewery to lower operational costs, and it alleviates safety considerations like moving kegs, falling kegs and the chemicals used to clean kegs.

Scalable wastewater treatment tech sized right for craft breweries

Aquacycl is a wastewater technology company that helps food and beverage businesses more effectively treat wastewater while saving up to 90 percent in treatment costs. The company’s BioElectrochemical Treatment Technology (BETTTM) uses naturally existing bacteria to convert organic waste and sludge into direct electricity without any methane production. BETTTM is distinctive in the industry because it can treat wastewater with up to 150,000 milligrams of Chemical Oxygen Demand (COD) per liter without the need for dilution, and it can treat wastewater that is five to ten times stronger than what conventional technologies can provide.

Aquatherm’s colorful and versatile piping system

What’s that green and blue pipe, you ask? Ahh. It’s a polypropylene piping system (or PP). The brand is called Aquatherm. Catches your eye, doesn’t it? Besides its bright, colorful appeal, this unique plastic pipe offers numerous benefits in a brewery, say, compared to metal or other plastic piping systems. For starters, PP is much lighter than metal. It will not corrode or scale, and it is connected by virtually leak-proof heat fusion, which is quite useful as a brewery’s infrastructure can be an annoyingly complex set of zigzags (as you know well).

What size glycol chiller do you need for your craft brewery? Check out Thermal Care’s sizing calculator

Temperature control is immensely important in the beer-making process, and it’s controlled through a variety of equipment — from heat exchangers and boilers to cooling jackets and commercial walk-in coolers. Maintaining the correct temperature is a process that continues throughout the entire brewery, and Niles, Ill.-based Thermal Care wants to be there to help at many points. Thermal Care is a leading manufacturer of custom process cooling equipment and systems, with a focus on glycol chillers that can be used at many stations in the brewery or packaging hall — cooling for wort; controlling fermentation; crash cooling vessels; and prepackaging and product storage.

Self-serve beer taps are differentiating all kinds of on-premise business models

The pour-your-own beer concept is intriguing for the flexibility it allows customers, who can taste more drinks for a fair price while cutting out any wait time. But the self-serve technology is also opening up new possibilities for establishment owners too via lower operating costs, better space utilization and just being different than others around town. Self-serve beverage dispenser technology company iPourIt, for example, announced four new taproom wall installations in as many weeks. This isn’t too noteworthy on its own as iPourIt systems are now located in over 180 locations, but what stands out to me is the diversity of the concepts leveraging the system and their reasons for doing so.

The ultimate beer serving truck made by Isuzu

Isuzu celebrating 35 years of selling trucks in America in 2019, and today the company rules the small but important low-cab forward market in America. Like all chassis cabs, these low-cab forward units can be upfitted for a zillion different vocations — from landscape dump bodies to hauling flatbeds. Isuzu Commercial Truck of America Inc. has developed this awesome beer buggy in collaboration with Supreme (a custom body maker), Delivery Concepts Inc. (a manufacturer of specialty temperature-controlled upfit solutions for the food and beverage industries) and Bottle Logic Brewing (an Anaheim-based craft brewer).

Check out the LumiFlo LED light for your brewhouse sight glasses

There’s a reason the creation story starts with “let there be light.” Even god needed to see what s/he was doing. For this reason, we recommend you gods of beer creation check out LJ Star’s LumiFlo LED light for inline sight glasses. The LumiFlo is an innovative hands-free solution that can be easily attached to most inline full view sight glasses in process fluid lines. This allows operators to clearly see color, flow and particles moving through the sight glass. You can visually inspect product quality, clarity, viscosity and consistency. It also allows for better inspection during cleaning and rinsing.

[…] Gear up: Cool new equipment and vessels that can upgrade almost any craft brewery (Craftbrewingbusiness.com) […]