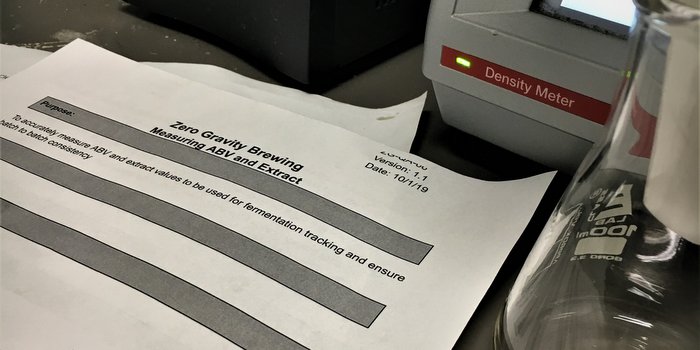

In this series of articles, Amy Todd, owner and operator of Zymurgy Labs, a third-party beer testing lab, who also works part-time in the lab at Zero Gravity Craft Brewery, gives us a detailed ground-floor view of the day-to-day lab routines that separate quality craft breweries from the pack.

Appearance, golden/orange hue, moderate haze, pass. Aroma, citrus, berry, little pine, pass. Mouthfeel full bodied, soft finish, no astringency, crisp pop of carbonation, pass. Flavor, overall impression, pass, pass.

On to the next.

Every Wednesday and Friday I set up and run a sensory panel, or “taste” for short, at Zero Gravity. We recently switched to a more independent pass/fail format on the above attributes from a longer survey, which provided more detailed information, but also took up more of everyone’s time.

The brewers and packaging folks are evaluating our beer on an informal basis throughout the process and taste is a formalized way of evaluating packaged beer for the week. And when I say “formalized” I just mean we write it down. Using GoogleForms, which automatically sends results to a spreadsheet for later review.

Setting the sensory mood

Taste is held in the brewery’s tasting room from 10-11 twice a week. Since the tasting room doesn’t open until 12, this gives everyone plenty of time to come in, evaluate up to four beers and clean up before customers come in. There’s plenty of glassware, space to spread out or sit together if we’re training, sinks for dumping extra beer and a dishwasher. It’s free from distractions, and an environment our customers will be sampling our beer in. It’s early enough that the popcorn machine hasn’t started and there aren’t too many savory aromas drifting in from the kitchen next door. Most folks have finished their coffee by then and haven’t had lunch yet which can all impact the sensitivity of their pallets.

A sensory panel can help you identify off flavors, aid in troubleshooting problems in the brewery, and make sure you’re producing beers that are true to brand. It’s an inexpensive way to evaluate your beers before releasing them into the marketplace and an essential part of any quality control program. Your pilsner can be spot on for alcohol, bitterness, color, pH, free from any type of infection, yet have a slight cooked corn flavor that wasn’t in the last batch. Or your Belgian pale ale could be lacking that spicy black pepper note your customers have come to expect.

When we first started taste about a year and a half ago, my co-worker Griffin and I held a series of training sessions. First we discussed how to evaluate a beer.

Appearance

Take a look at the beer, look for color, haze, head retention, lacing. The appearance is your customers’ first impression of that beer. Does it meet true to brand expectations? You could use pictures to compare along with a description of that beer.

Smell

Some aromas are volatile and can dissipate quickly so you want to smell the beer right away. Start with a drive-by sniff as you hold your glass a few inches from your nose and smell as you pass the glass in front of you. Make some initial notes as the aroma might change a bit as the beer warms up, volatile aromas disappear, or you become anesthetized to some of the aromas.

Next take a few quick short sniffs and then a long slow one. You can cover your glass with your hand and swirl to trap some of the volatiles and then smell. Be aware of any perfumes that may be on your hands from lotion or soap.

Taste

Take about an ounce of beer in your mouth and try to coat the inside. Let it come in contact with the top and bottom of your tongue, the sides, as well as you lips, teeth and gums. Think of it as “chewing the beer.” Swallow and exhale through your nose. Note initial impressions of flavor, malt, hops, yeast, alcohol, sweetness and aftertaste. What other flavors do you notice?

Feel

Take another sip and think about the viscosity and carbonation level. High or low? Full or light body. You can think of body in terms of skim milk vs. whole milk, they feel different in your mouth. Carbonation level can play a big role in the overall impression of a beer, so much so that it’s included in style guideline descriptions. We increased our CO2 specs after repeated comments at taste of low carbonation.

Go back to the smell

See if anything has changed as the beer warms up. Note any malt, hops, yeast and fermentation byproduct aromas. Is this what you would expect for this style?

Now pull it all together and think about your overall impression. Is this beer true to brand?

Ingredient training

Next, we held some ingredient sessions. We tasted malt alongside the beers those malts went into and talked about what flavors came through in the final beer and how the flavors changed during the fermentation process. We did the same with hops and yeast (we just smelled those).

Another fun way to look at flavors is to try some of the same beer styles you make from another brewery, see how they compare and how they’re different. Sometimes it’s easier to come up with a description of your beer when you have something to compare it to.

Off-flavor training

Off-flavor training will be the biggest investment, besides time, for your sensory panel. If you’re on a tight budget, start with ingredients and true to brand descriptions for each of your beers. At some point though, you will need to actually taste and train on off flavors. Many spike kits are sold to use in one liter of beer, enough for 10-12 people. If you have a small staff, consider joining forces with another small brewery, or even some homebrewers.

When training on off flavors, always have an unspiked control beer for comparison. Use a mild beer such as an American lager during new flavor introductions. Let participants try the spike on their own without any talking. It’s important to come up with your own descriptions of the flavor without being influenced by what others experience.

After everyone has had a chance to taste, ask what everyone perceived. Some people may have recognized a flavor but couldn’t name it. Training in a group helps provide a common language to effectively communicate any problems. Share what the spike was and some common descriptions. Finally, share some causes of the off flavor and ways to prevent it. Linking the off flavors to causes and solutions in the brewery helps with understanding.

Off flavors may present differently in different beers or at different intensities so it’s important to keep training and experimenting with off flavors and different base beers and intensity levels. The more you train, the easier it will be to detect an off flavor, should you come across one in the wild.

There are plenty of places to purchase off flavor spike kits, such as Siebel, Aroxa, Weber Scientific, Flavor Active, Sigma Aldrich , Amazon and the grocery store. Kits can be purchased as a set of basic off flavors for beer, or some places will let you mix and match different flavors.

Don’t forget to train on “on” flavors as well as off flavors. If you have an off flavor you may be particularly prone to, such as diacetyl or DMS if you brew a lot of lagers, make sure you’re training on those frequently and that you have panelists who can pick those flavors out. A trained sensory panel can act as another instrument in your quality control program.

Triangle Test

After everyone has trained on an off flavor, I like to test panelist on it using a triangle test. For this test, you have two samples that are the same, and one that is different. One will be your control, or unspiked sample, and the other your spiked sample. See if panelists can pick which one is different and then go another step and see if they can identify what the spike is. There are six possible combinations, AAB, ABA, BAA, BBA, BAB, and ABB that should be randomized.

Triangle tests are also great for trying out a new process or recipe change. If 20 lbs of citra dry hops tastes the same as 25 lbs, you could save a lot of money. Don’t tell panelists anything about the test, except that two samples are the same and one is different. You’ll have to look up the statistics yourself on this one but you can determine if there’s a noticeable difference between samples based on how many participants can pick out the odd sample. The order that you present the samples in can make a difference so make sure you switch it up.

Duo-trio

A similar test is a duo-trio test. Participants are presented with one control beer and two additional beers they must compare to the control. Here they’re trying to pick out which beer is the same as the control.

Sensory often falls on the lab folks, but if you don’t have a lab or dedicated quality control person, anyone can set it up. Large breweries have sensory departments where one or more employees are dedicated to managing a sensory program. Find what works for your brewery. A sensory program is easily customizable and you can make it as simple, or as complex as you want. Start out small and build it out as you go. Get folks in the habit of attending taste and evaluating beers and sprinkle in some training. Don’t forget to include everyone in the brewery, not just those on the production side.

There’s a lot of effort involved in making beer, but if it doesn’t taste good, your customers won’t keep coming back. So don’t give them a reason to not come back. Evaluate your beer before you send it out.

Amy Todd is the Owner and Analyst for Zymology Labs as well as a lab manager for Zero Gravity Craft Brewery in Burlington, Vt.

Leave a Reply

You must be logged in to post a comment.