Moon Dog Craft Brewery is independent, Australian-owned and fast approaching its 10th birthday. Originally set up in the Melbourne suburb of Abbotsford, Moon Dog has now outgrown that facility and is on the move to Preston where the team has just opened a 12,000-sq-meter facility. The site will house a 725-person venue with a large new brewing facility about to be commissioned, which will allow them to produce over 10 million liters per year.

Seeing the need to bring more efficiency into its processes, Moon Dog ordered a GEA Visitron Filler All-In-One in August 2019, as well as a water deaeration system VARIDOX, a DICAR-B carbonation system, an ECO-FLASH pasteurizer and a Plug & Win 100 centrifuge from the technology group.

“We chose GEA because the company has a great reputation for manufacturing high quality machines,” said Josh Uljans, cofounder and CEO of Moon Dog Craft Brewery. “The All-In-One filler allows us to operate a single filling line for both cans and bottles with quick change-over between formats. This gives us benefits in terms of floor space utilization and simplicity in maintenance and operation.”

One for all: ALL-IN-ONE

Breweries often have a reason for filling both cans and bottles, but doing both in a small footprint is often a nightmare. GEA developed the All-In-One monoblock filler as a direct response to sustainability requirements and is a prime example of just how lean and flexible filling solutions can be.

The compact All-In-One rinses, fills and caps products all within a small production footprint. Its sophisticated process design saves time during filling and format changeovers. Within a matter of minutes, the machine can switch to handle different products and container formats.

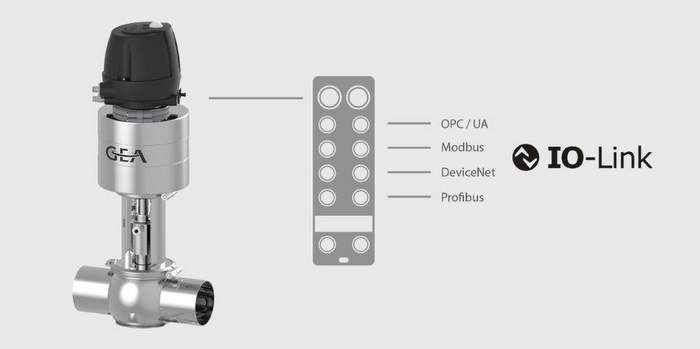

This is made possible by the All-In-One’s multifunctional elements: the rinser is equipped with universal grippers; the filler uses an electro-pneumatic filling valve; and a single capping turret is able to accommodate different closure types.

“The All-In-One’s multifunctional system is unique in the world, because it allows for an unprecedented level of flexibility. It can be used to fill glass, cans and PET containers, handle different formats and seal them with diverse cap types and can fill carbonated or still drinks, using a hot or cold fill method,” said Jakob Salamun, sales manager at GEA VIPOLL.

Leave a Reply

You must be logged in to post a comment.