The craft beer market is maturing. Breakneck, anybody-can-start-a-brewery growth has eased into a steady and healthy market but with stiff competition. Consolidation in the industry continues in a fight for regional and national growth (see Platform and Founders recent transactions), and brewers are diversifying into other social lubricants from hard seltzers to

non-alcoholic cannabeers to hedge their bets.

This market maturation also means the process of producing and serving beer is changing and getting more advanced. A competitive industry ultimately leads to businesses looking for leaner and smarter business practices to find an edge. Here’s a good example: What if you could get rid of your kegs (at least in-house)? What kind of money could you save? What about time? What about space? What about getting rid of that cold room? Add in factors like increased safety and the need for fewer employees, and the idea of going kegless can sound very attractive. But how would one go about doing that?

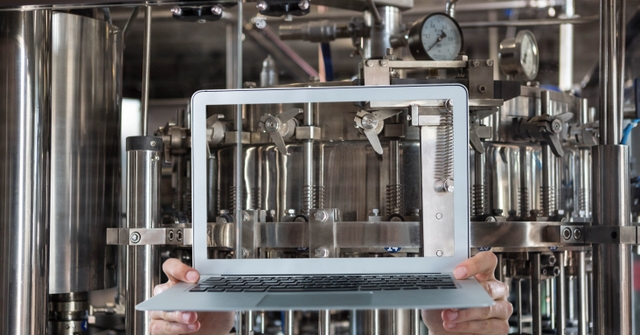

Enter Paul Mueller Co. serving beer tanks. These steely, sweet-looking serving tanks utilize a self-cooling, bag-in-tank system that can be used directly in a taproom. These tanks allow breweries to transfer the carbonated beer straight from a brite beer tank with the ability to serve in just a few hours. No need for kegs in the brewery. This allows a brewery to lower operational costs, and it alleviates safety considerations like moving kegs, falling kegs and the chemicals used to clean kegs.

Without additional headspace and CO2, the beer stays fresher too. There’s one less step from the tank to service and the beer can be precisely temperature controlled and serviced from the tank. Because it is not necessary to CIP the tanks, you don’t even need a floor drain at or near the tanks.

Wilmington, N.C.’s Mad Mole Brewing is a fan. It’s been using twelve 1,000-liter Paul Mueller serving beer tanks since early 2018, without a cold room in the building.

“[These serving beer tanks take] me 30 minutes to an hour to push the beer in and to get everything prepped for the transfer,” says Neil Blake, brewer at Mad Mole in the video above. “Then once the beer is served, it maybe takes me five minutes to clean it, which kegging itself is pretty timely. You can keg off the full brite in four or five hours. And then once those are done, it depends on your keg cleaner, but two to three kegs at a time. So, that’s about a full day — where this takes maybe two hours all together.”

Watch Blake and friends discuss these Paul Mueller Co. serving tanks in the video at the top of this post. The brewery pushes out the beer to the serving tanks with a compressor, so they save a lot on CO2 as well, which is not cheap. It takes no chemicals to clean these tanks. Brewers just take the bag out, sanitize the valves and put a new bag in there. On top of all these business advantages, the taps just look slick hanging off these unique beer vessels, providing a truly unique tank-to-tap experience for your patrons.

“Like going from the typewriter to the computer, it’s hard for an industry that’s always known kegs to realize there is a more efficient way. Along with efficiency, the sustainability, the space and energy savings of serving tanks is easy to implement in any brewery-in-planning,” said Serving Tank Sales Manager Jon Sprenger. “Tanks can be stacked on racks, hung from the ceilings and fitted to just about any layout. For existing breweries, the transition from kegs to serving tanks is also possible, you can utilize your existing cold room with single wall tanks, or install double wall tanks with direct draw to your taps. Also, installation is simple. Put together a frame, set the tank, hook up glycol and air, insert the bag and fill the tank, and you are ready to pour.”

The Serving Beer Tanks are available in sizes ranging from 250L to 1,500L. Costs, including valves and inliners, fall between $5,000 to $8,500.

Jim Harris says

@PaulMuellerCo @madmolebrewing As a 34-year-old guy with 84-year-old back, I am all in favor of re… https://t.co/lGondb3iyo