Aquacycl is a wastewater technology company that helps food and beverage businesses more effectively treat wastewater while saving up to 90 percent in treatment costs.

“More than 80 percent of wastewater is discharged or land-applied without any treatment because the current technology is cost prohibitive,” said Orianna Bretschger, CEO of Aquacycl and one of three co-founders. “We are providing food and beverage producers with technology that will save them up to 90 percent in wastewater treatment costs. We are proud that our investors recognize the critical problem we are solving for.”

Aquacycl says its treatment options are plug-and-play, energy neutral. The company’s BioElectrochemical Treatment Technology (BETTTM) uses naturally existing bacteria to convert organic waste and sludge into direct electricity without any methane production. BETTTM is distinctive in the industry because it can treat wastewater with up to 150,000 milligrams of Chemical Oxygen Demand (COD) per liter without the need for dilution, and it can treat wastewater that is five to ten times stronger than what conventional technologies can provide.

Dario Guerra, cofounder of Joshua Tree Brewery, has been using the technology for over a year and says his brewery couldn’t exist with out it.

“Without the BETTTM system, the city wouldn’t let us open our brewery because they didn’t have infrastructure to treat the high-strength wastewater. Aquacycl has allowed us to focus on making great beer, and they have consistently been hitting home runs for us.”

The woman-owned company closed a $4M seed round led by the Roddenberry Foundation that will help the company expand its sales and marketing efforts as well as scale manufacturing, so we wanted to learn a bit more about how this may impact craft breweries.

Thanks to Baji Gobburi, VP of sales, for the answers below.

Could you explain a bit more what is different about this technology compared to other systems out there?

It’s unique in the sense that it is the only technology that can treat very high strength waste. “Very” is the key word here. There are many anaerobic technologies that can treat waste to 10/15,000 mg COD/l. There are systems that can go up to 30/40,000 mg/l. However, they basically trickle feed the very high strength. Pure beer is around 150,000 mg/L or higher. So what happens when you have a bad batch of beer? You end up needing a “calamity tank” or shock your wastewater system that potentially kills the bacteria and causes nightmares to operators downstream. Most of the systems can’t handle solids and are very finicky when it comes to temperature of the incoming waste streams.

What we do is we can handle very high strength waste – up to 150,000 mg/l of COD loading and a good amount of suspended solids (up to 3000 mg/l). A wider range of temperature also allows us to be a more flexible system.

What would make it attractive to a craft brewery? Is it a more affordable price point? Is it sized just right? Is it something specific about its capabilities?

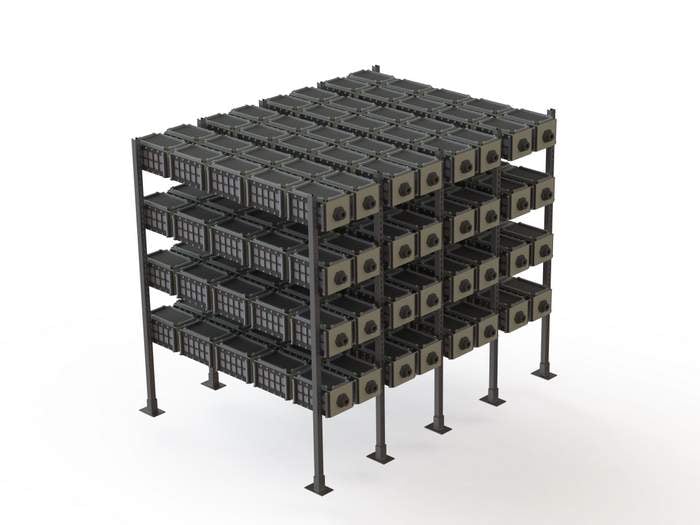

We have standard reactors (picture a car battery) which are small, modular and easy to scale. They have the same feel of a server rack you see in the data storage industry. Since we do this on a pure service platform, there is no upfront major capex to the brewery and we grow when they grow.

In the case of a brewery, if the most “dirty” water is the first couple rinses of the tanks, systems are designed to treat all 4 or 5 rinses (brewery dependent). Hence breweries have wide water to beer ratio (from 4:1 to 9:1.. craft beer only.. typically being 6:1). Their waste treatment systems also are large to treat all of the wastewater. Example: In a 1,000 bbl brewery, wastewater plants tend to be 5,000 bbl capacity (1,000 goes in product plus there are some evaporation losses). Only 2,000 bbl is the really bad stuff while the rest is relatively clean water. What we can do is design a system for just the 2,000 bbl, but it comes with all the bells and whistles of net neutral energy, 80 percent reduction in solids etc.

We can do up to 150,000 gallons per day but those are large craft breweries. A 1,000 bbl brewery has about 450 gpd of wastewater. So we address 95 percent of the craft breweries out there.

Leave a Reply

You must be logged in to post a comment.