Brewers are busy manufacturing environments where vessels, liquids, ingredients, machinery, packaging, forklifts, foot traffic and lots more compete for limited space. The brewery flooring beneath that hodgepodge of machine, man and product should be a sturdy, easy-to-clean, long-lasting and attractive work platform, but the ideal flooring for your particular facility can vary depending on a few different factors.

In order to fill you in on everything you need to know about brewery flooring, let’s go over the types and how you can optimize your floors.

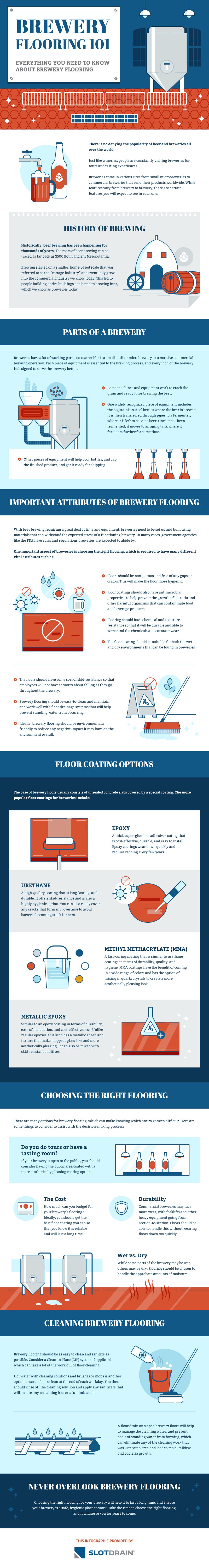

Choosing the right brewery flooring

No matter what kind of brewery you have, your floors need to possess these qualities:

- Suitable for both dry and wet conditions

- No gaps or cracks

- Non-porous

- Resistance to moisture and chemicals

- Antimicrobial floor coating

- Resistant to temperature change

Your floors will also need to be non-skid and easy-to-clean with the right drainage system. It’s a good idea to create and maintain your floors with chemicals and practices that are environmentally friendly as possible to avoid breaking regulations or harming the environment.

What kind of floor coating should you use on brewery floors?

You have a few choices for what to coat your floors with. Epoxy is easy to install, durable and cheap. You have to re-apply it every few years though. Urethane lasts much longer and is very hygienic. You are also able to fill in cracks easily, preventing bacteria. MMA or methyl methacrylate offers the same quality of urethane but has more to choose from in the way of color variety. You can even get it in a quartz crystal coating. Metallic Epoxy is like regular epoxy, but it has a metallic sheen to it. This makes it look glassy, and it can be combined with non-skid additives.

What brewery drains should you use?

Brewery drains are very important, and a good kind to use are slot drains. They are neat, efficient drains which run the length of the floor. They can handle heavy traffic and are very easy to clean. Other less effective options include sloped drains and grated drains. Depending on how much foot traffic you’ll be having and who you plan on walking the floors, you may want to adjust your approach. Heavy-traffic areas with large equipment might be better off with a traffic rated trench drain. More traffic means the drain will need to be more durable than other areas. Also, if you plan on having guests on the floors, you may want to choose a better-looking floor coating.

There are many things to consider when creating and maintaining your brewery floors, and all are of equal importance. By choosing the best type of flooring, the best floor coating, and the best drains for your situation, you can optimize your brewery floors to the fullest extent.

For more information, check out the infographic below provided by Slot Drain.

Matt Lee of Innovative Building Materials works with several companies in the building materials industry to bring awareness to their brands.

Chris Davis says

Gregg Wigen

Slot Drain Systems says

Thanks for keeping the knowledge flowing !