In 2019, the German malt producer Palatia Malz GmbH celebrates its 120th birthday. The third-generation family-run business with its headquarters in Heidelberg was founded in 1899 as a flour mill near Kaiserslautern. Today, Palatia Malz sells a full range of base and specialty malts to breweries, distilleries and the bakery industry under the well-established BESTMALZ brand. This autumn, the big birthday will be celebrated together with the inauguration of a state-of-the-art warehouse and logistics center.

In the beginning there was flour

On November 4, 1899, the company was opened in Kreimbach-Kaulbach (West Palatinate) as a flour mill and rebuilt five years later into a malting plant. Max Göhler, grandfather of the current managing director and majority shareholder, acquired the malting company in the 1930s. In the following four decades, he developed the business into an important player in the German malting industry.

Foresighted investments in production and logistics

Max Göhler’s son Eberhard joined the family business after finishing his studies, and continued his father’s work. Eberhard Göhler pushed the technical development of the company forward and invested heavily in the production of malt in the Kreimbach main plant. In 1987 he acquired a second malting plant in Wallertheim in Rheinhessen. Wise logistical considerations were the decisive factor and are practiced to this very day: the plant is conveniently located near the Rhine ports of Mainz, Wiesbaden and Worms, facilitating short export routes via Antwerp and Rotterdam. The location at the Alzey highway interchange with direct connections to Cologne and Frankfurt is also ideal for transport by land.

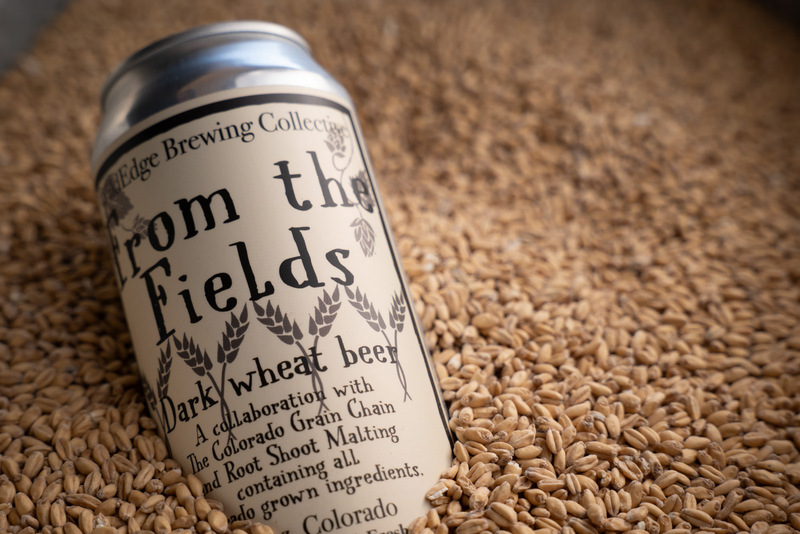

Under the leadership of the third family generation, Palatia Malz paved the way for international sales shortly after the turn of the millennium. In addition to building the Bestmalz brand, investments were made in a bagging and roasting plant to supply customers with so-called craft malts for artisan beers. “When the global boom in craft beer broke out at the beginning of this decade, we were very well prepared with our top-quality requirements, excellent logistical connectivity, efficient facilities and an internationally respected brand. The high-quality craft malts are in high demand by hobby brewers, brewpubs and breweries of all sizes,” says CEO Dr. Axel Göhler. “What unites the three family generations is the ability to recognize the signs of the times, while at the same time not losing sight of quality and tradition. That’s what my grandfather did in the difficult years of the post-war era, and that’s what we’re all about today,” he says, looking back at the company’s history.

Tradition, quality and innovation go hand in hand

Dr. Axel Göhler, the grandson of Max Göhler, joined the management in 2014, streamlined the group of shareholders and accelerated the company-wide renewal process. Today, he and two non-family directors are at the head of the nationally and internationally rapidly growing malting group.

“In the brewing industry in general, and especially in medium-sized companies, we are currently facing major challenges – for example digitalization,” says Dr. Axel Göhler. “But there are also many opportunities and we are determined to seize them!”

Always keeping an eye on quality, the traditional malting group has for many years relied on artisanal “slow malting” combined with state-of-the-art technology. The company has implemented electronically supported innovative food technology processes which continuously control production, quality and logistics. The malt portfolio comprises over 50 standard products. Besides basic and special malts, this also includes organic malts and malt made from the traditional barley variety Barke. In addition, the company also fulfills custom production orders for large customers from Germany and abroad. Palatia Malz products are sold to more than 300 customers in Germany, Austria and Switzerland as well as through certified dealers abroad.

In the anniversary year 2019, a state-of-the-art warehouse and logistics center will be put into operation at the Wallertheim site.

“This will enable us to deploy our malt products in small, medium and large packaging units more rapidly in the future,” says Dr. Axel Göhler.

Leave a Reply

You must be logged in to post a comment.