How’s this for a sales pitch? For a month, try out this innovative, specialty brewing vessel — say, an infusion system that allows you to experiment hardcore and decrease waste and headaches — and if it doesn’t meet your expectations, then you don’t need to buy it. All you have to pay is shipping.

I noticed that expert beer equipment manufacturer Paul Mueller Co. is offering a “Try Before You Buy” 30-day program for one of its coolest vessels — the space-age-sounding maxxLūp.

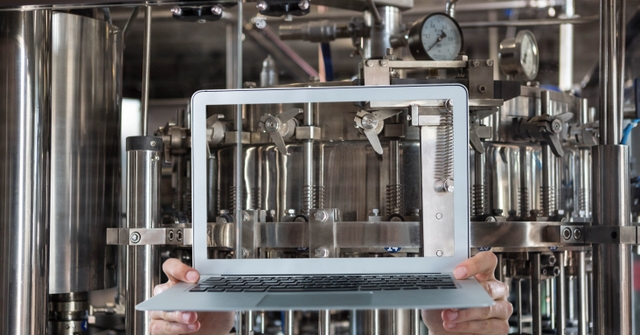

At a quick glance, it almost looks like a ’60s-era space capsule. The maxxLūp beverage infusion system is just as cool. It’s an ultra-efficient dosing system that can be moved around the brewhouse and cellar, and it can be used beyond beer. It actually comes on wheels, and as part of the Try Before You Buy program, the folks at Paul Mueller will actually deliver the maxxLūp system to a brewery’s front door, and brewers can just wheel it in. After a month-plus, Paul Mueller will pick it back up. All the brewery pays for is the shipping.

How does it work?

So, first off, this circulation tank tackles the inconvenient process of dry hopping. The tank sits on casters, so brewers easily move the maxxLūp around, going from the brewhouse, where it can function as a hopback, to the cellar, where it can be used to safely dry hop without needing to access the top of a fermenter.

“The maxxLup is a mobile ASME-rated pressure vessel with tangential inlets — like a whirlpool [see photo below],” explained Matt Kramer, Paul Mueller national sales engineer. “There’s an internal screen, integrated spray balls for complete CIP and two outlets — one for product and one for spent ingredients. The maxxLūp arrives at the brewery with all necessary valves and pressure relief devices.

“To use it, the operator uses hoses and a pump cart to set up a temporary recirculation loop between the maxxLup and their fermenter or kettle. After adjuncts or hops are loaded into the maxxLūp through the top manway, the operator purges the maxxLūp with CO2 to minimize O2 pickup and begins recirculation for flavor extraction. During recirculation, beer flows into the maxxLūp through the tangential inlets, causing the beer to swirl through the ingredient before passing through the internal screen, flowing out of the product outlet and back to the fermenter or kettle.”

“The recirculation loop can be done using the same hoses and pumps that most breweries already own,” Kramer continued. “The generous outlet height allows room for a trash can to be placed under the maxxLūp after extraction. The operator then opens the large butterfly valve to easily remove the spent ingredient. When it is time to clean, a CIP can be performed using the integrated spray balls to rinse the unit for its next task. The removable screen is cleaned during CIP with the integrated spray balls, but can easily be pulled for a thorough inspection.”

Using a removable screen design, the maxxLūp also allows for the handling of a wide variety of adjuncts with increased efficiency (coffee, spices, fruit, swallow’s nest, almost whatevs). Paul Mueller is claiming up to a 50 percent reduction in ingredient amounts while still achieving the same or even better sensory analysis with the maxxLūp.

“Depending on volume and ingredients, the complete maxxLup recirculation process takes two to 12 hours, a significant reduction over traditional steeping methods which can tie up a fermenter for several days,” Kramer said. “When the extraction process is complete, CO2 is used to blow down the maxxLup to return the beer back to the tank, minimizing the loss.”

30-day trial details

I guess the company feels confident, since it’s letting breweries test it out for a month plus basically free. Here are the details on the Paul Mueller’s 30-day Try Before You Buy program:

- The maxxLūp in one of two sizes: 50 or 200 gallons for the loaner program

- All necessary valves and attachments for safe operation

- Shipping arrangements managed by Mueller

- Use of the maxxLūp for up to 6 weeks

- See how much you can start saving in your process with the maxxLūp ROI calculator.

Here are the features of the maxxLūp:

- Up to 50 percent reduction in hop and adjunct use while achieving the same or better sensory analysis

- Elimination of lengthy steep times for adjuncts

- Available in 50-, 100- and 200 –gal models for purchase (50 and 200 models available for Loaner Program)

- Large outlet valve allows for easy removal of spent hops and adjuncts

- Dedicated spray balls for the vessel and screen ensure complete CIP

- Motor-free design employs fluid flow to harness the essential oils and resins in hops and adjuncts while mitigating the risk of shear damage

- The configuration of the maxxLūp allows the vessel to be purged, reducing the introduction of unwanted oxygen into the product

- Removable screen design allows for thorough inspection and works with a variety of ingredients including cone or pellet hops, coffee, spices, and fruit

- Designed for use in both cellar and brewhouse with casters that allow the user to move the vessel throughout the brewery

- Eliminates the need to access the top of the fermenter for dry hopping

- Pressure rated and ASME Code-stamped options are available

- Financing options available

“The motor-free design harnesses flow to circulate beer through the ingredients while mitigating the risk of shear damage,” Kramer said. “Contact between the beer and the ingredients is maximized which improves utilization and speed of extraction while minimizing the potential for off flavors that can develop with extended exposure.”

Leave a Reply

You must be logged in to post a comment.