Wastewater is a problem that almost every facility has to deal with. However, beverage facilities like breweries, especially need an effective strategy for maintaining and disposing of their wastewater. Any brewer worth his or her salt will have wastewater management near the top of their list when it comes to running a brewery. The consequences of not properly managing wastewater in a brewery can range from legal ramifications to environmental damage and more. Breweries deal in a variety of harmful chemicals and contaminants which cannot just be flushed down the toilet. If you want to manage your brewery wastewater without issue, here are some tips you can use to make sure your facility isn’t having a negative impact on the environment, your customers, or anything else.

What makes brewery wastewater harmful?

There weren’t always such strict regulations on brewery wastewater. Until 1972, breweries could essentially dump their wastewater wherever they wanted to. There were no regulations surrounding the management or disposal of it, and wastewater was often poured directly into rivers or lakes as a result. We’ve since learned that this practice is absolutely terrible for our waterways and the marine life that lives in them. Typical brewery wastewater consists of high levels of sugar and alcohol, a low pH, high temperatures, and a large potential for things like high solids.

Not only is this combination bad for the water it’s dumped into, it’s a lot harder for plants tasked with wastewater management to clean. This is because the combination of all these chemicals and factors create a higher biochemical oxygen demand. A higher BOD means the treatment plant dealing with this kind of water has to use more electricity to clean it.

Tips for managing brewery wastewater

1. Use the proper piping

Because most brewery wastewater contains a high pH level, it’s known to eat away at drains and pipes if not kept at a certain level. Hydrogen sulfide gas is also produced by your brewery’s wastewater. This gas is extremely powerful and can eat right through rebar as well as concrete. For this reason, stainless steel and certain durable plastics are your best choice for pumping and piping materials.

2. Separate your solids

When solids get flushed down the drain, they turn into sludge at the wastewater management plant. This sludge needs to then be removed, which takes extra time and effort. It can be hard to avoid getting any solids mixed in with your wastewater, but with the proper drainage system you can avoid a really problematic level of solids getting mixed in, for the most part.

3. The right kind of drainage system

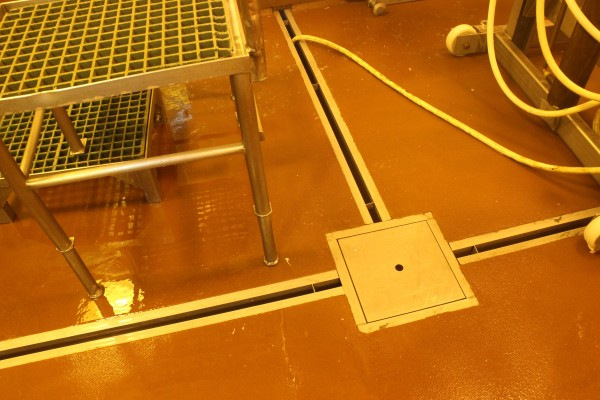

This is the single most important aspect of properly maintaining the wastewater at your brewery. The right drainage system can do wonders in terms of preventing solids from getting mixed in with your wastewater. Many brewers today use a traditional trench drainage system, but these have many drawbacks. Most aren’t made with durable material, meaning they let the acidic, corrosive wastewater eat away at them. Brewery trench drains are also incredibly hard to clean, often resulting in huge cleaning bills or worker injury, should you have your employees do it.

Slot drains, in comparison, are a much better choice. They are long and thin, requiring no covering at all. They are also made from stainless steel, meaning they stand up to corrosive brewery wastewater with ease. Because they are so thin, it’s also a lot harder for solids to slip into the drain and get mixed up with regular wastewater. You can also opt for a slot drainage system that includes a catch basin, making it nearly impossible for solids to make it all the way through your drainage system and into the wastewater treatment facility you use.

Don’t take chances with your wastewater

Harmful brewery wastewater can wreak havoc on waterways, marine life and wastewater treatment employees if it’s not properly managed. The pH levels of this toxic runoff, combined with the high levels of sugar and alcohol inside it, make managing it a task all of its own. If you want to make sure your brewery wastewater isn’t causing problems, you’ll need the proper kind of pumping and piping material, a method for separating your solids, and the right kind of drainage system. Use stainless steel pipes and pumping equipment to ensure they don’t break down over time.

By implementing a slot drainage system you can kill two birds with one stone when it comes to managing your wastewater. Slot drains are made from stainless steel which will not break down over time. They also make it harder for solids to slip in, thanks to their slim design. The option to add a catch basin which nearly eliminates the inclusion of solids into your wastewater is another bonus as well.

All in all, by using each of these tips to manage your brewery’s wastewater, you can shrink your chances of damaging your own piping, or worse, the environment. You’ll also make it much easier on your local wastewater treatment facility and you’ll stay well within whatever regulations you have in your area regarding wastewater disposal.

Matt Lee of Innovative Building Materials works with several companies in the building materials industry to bring awareness to their brands.

Leave a Reply

You must be logged in to post a comment.