Happy National Beer Can Appreciation Day! I know you celebrate it all year-round like we do, by crushing beers packaged in cans, but today is a day to reflect on those crushings. Cans have come a long way in the national beer consciousness, and in honor of the occasion, we present the top five features from the Craft Brewing Business archives covering craft beer canning tips and trends.

Let’s learn the science behind canning craft beer (with a special focus on seamers)

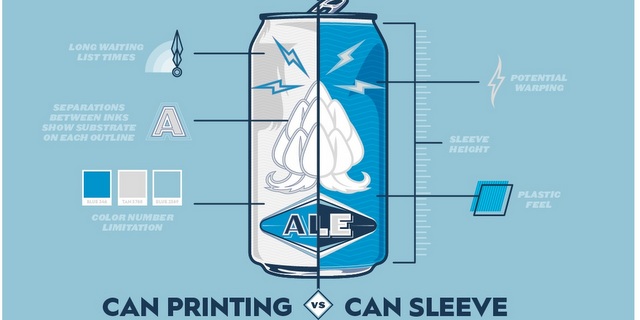

The pros and cons of printing on cans vs. using can sleeves

Garnering attention over the past couple years, can sleeves are digitally printed and shrink-wrapped to the surface of the can. There are distinct advantages and disadvantages for sleeves, and below is a short summary from a packaging design perspective.

The craft beer revolution has taken the world by storm, but as craft breweries multiply and gain more market share, new challenges arise. Here’s one: seaming cans reliably and consistently. Modern cans have remained largely unchanged for more than a century, with their origins dating all the way back in the 19th century, and this has remained one of the most popular means to store and transport food and beverages ever since.

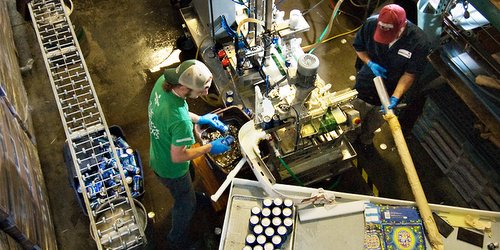

What to see CBC 2018: Canning line innovations, from fillers to mobile depalletizers

Hey, the Craft Brewers Conference and BrewEXPO America is right around the corner, taking place in Nashville from April 30 to May 3. The trade show floor gets bigger and bigger every year, and to save you some time, we reached out to the exhibitors for a sneak peek of what they will be showing off at their booths this year. Stay tuned for the entire “What to see at CBC 2018” series over the next few weeks. It’s a great way to plan out your expo hall path and save some of that walking around time for drinking.

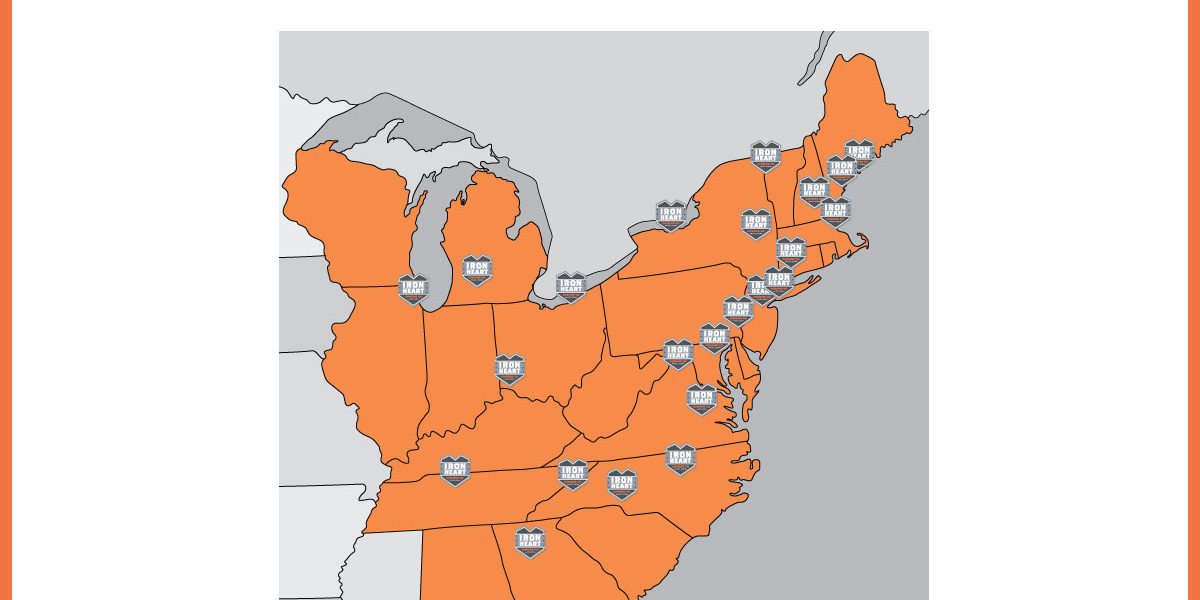

Goin’ mobile: Craft canning lines brought straight to your brewery door

What was once a taboo is now a trend. The sudden boom in interest by both craft brewers and craft drinkers in canned beers opens up new pathways for revenue. Jumping on this trend could increase interest in a brand by getting it in more hands and in more places, like ball parks and beaches and hiking trails, that bottles often cannot go.

But where there is opportunity, there are new challenges. Craft brewers, as innovative and entrepreneurial as they are, still have budgets, and often small budgets. Is adding a canning line to your operation worth the investment for a 500-barrel (bbl) brewer? When does the opportunity outweigh those risks? How can you capitalize on this trend without mortgaging your current business model?

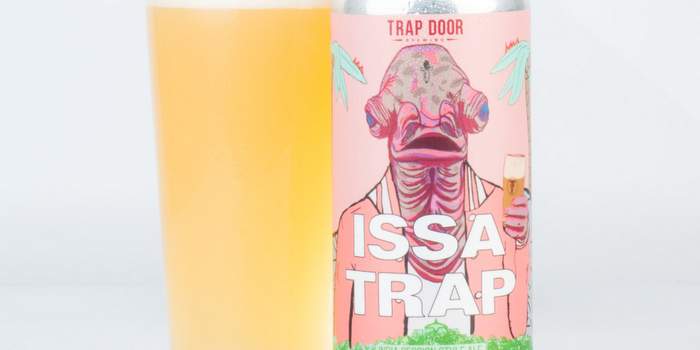

Shrink sleeves: A cost-effective labeling option for seasonal beers and one-offs

Craft beer customers and retailers ask every day what’s hot and what’s next? The answer is often the seasonal brews and one offs that brewmasters develop to satisfy the craving for new and different from the local or regional craft beer market.

The problem often encountered by these smaller breweries is the economics of can printing, which is based on trailer-sized volume orders of 200,000 cans and a limited number of colors that can be printed on a can. These factors make it difficult to print short runs requiring fast turnaround. Fortunately, shrink sleeve labeling, where brightly printed thin gauge film sleeves are applied over cans and then form fitted through a heat tunnel process, delivers an ideal packaging solution.

Leave a Reply

You must be logged in to post a comment.