Running a brewery is tough work. Not only do you have to monitor a dozen different things at once, you also have to make sure that your brewery will be able to withstand punishment in the long-term. Breweries require a unique combination of many different things that can take a toll on them, especially their floors.

Brewery flooring has to be some of the toughest stuff around if you want it to serve you for many years. It needs to be created with special chemicals that keep it strong and healthy, and it should have a variety of characteristics that allow it to remain strong in the face of heavy abuse. To help you obtain and maintain the strongest brewery flooring possible, let’s take a look at five tips you can use to make sure your brewery floor doesn’t fail when you need it the most.

1. Make sure your flooring is durable

Over the course of its lifetime, your brewery flooring will absorb a lot of abuse. It will take poundings from many different pieces of equipment and machinery like kegs, forklifts, trolleys, pallets, hoses, tanks and other heavy equipment that slides across the floor. These things can weigh up to thousands of pounds, which means your floor should be able to handle them without any signs of stress if you want to prevent failure. Use floor coatings to protect your bare concrete from abuse and use epoxy to mark areas that shouldn’t be walked on. Urethane is also great for reinforcing your concrete and making it harder to crack. It prevents any chemicals from seeping down into the inner layer of your floor and damaging it.

2. Try slip-resistant flooring

As you probably know by now, breweries are very slippery and wet places. There is a 99.9 percent chance you will have spills to deal with at your brewery, making it essential to use slip-resistant flooring. You should add an anti-slip additive to the resinous flooring of your brewery to give it more traction in case of slippery floors. Preventing slips and falls will not only save you money on potentially lost product, it will prevent you from having to pay out any lawsuits from people who have slipped and injured themselves on your floor. Slips and falls are the most common way to get injured and they cost the average brewery upward of $16,000 per year in the form of sick days and paid leave.

3. Use thermal shock resistant flooring

During the brewing process, you will be using both steam and boiling water to produce your product. Cold water is also used for wash downs, meaning your floors will be experiencing big temperature fluctuation quite frequently. By coating your floors in urethane you can prevent them from expanding and contracting every time they are splashed with hot or cold water.

4. Maybe consider chemically resistant flooring

In addition to boiling water, you’ll also have a lot of different chemicals coming in contact with your brewery flooring. Yeast, malt enzymes, alcohol, salt, cleaning agents, sugar, and acid are all potential threats to your flooring. Make sure you have a proper finish on your brewery floors to ensure that none of these chemicals ends up eating away at your floor, leading to catastrophic failure.

5. Make sure your floors drain properly

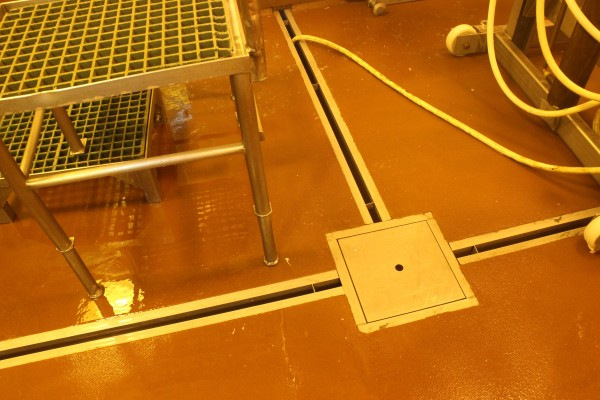

There are many different types of drains for commercial use. There’s a trend going on in breweries and many restaurants of using slot drains to drain the floors. Conventional drains are prone to bacteria buildup, and they usually have large grates over them that can crack over time. These drains cost a lot to clean, and they frequently get clogged with gunk.

Slotted drains, on the other hand, are small cracks in the floor running the length of the room usually. These drains are only about an inch wide and they are designed to handle drainage much more efficiently. They are built with stainless steel and created in such a way that there are no real corners or places for bacteria to thrive. These more efficient drains can be cleaned with a simple flushing method that is saving business owners everywhere around $15,000 per year in cleaning costs. Because this type of drain is so small, they don’t require any kind of covering. This is ideal because it eliminates the need for dangerous, breakable grates that are extremely heavy.

When it comes to draining your brewery floors correctly with the highest level of efficiency and the lowest risk of injury, it’s safe to say that slot drains are a huge step up compared to more conventional drainage systems.

Use these tips for the best results

If you want to prevent your brewery from having any type of flooring failure and potentially costing you thousands of dollars to repair, follow the five tips in this article. Proper drainage will solve a lot of your flooring issues. Make sure your floors are shock resistant, chemical resistant, slip resistant and durable for the best results possible. Checking all of these tips should set you up nicely for a long and prosperous career of brewing.

Matt Lee of Innovative Building Materials works with several companies in the building materials industry to bring awareness to their brands.

Terri Hays Jukes says

Guy

Melissa Luelling says

Aaron Luelling

Joe Hogge

Eric D Lussier says

Was gonna ping you last night after these guys followed me on Twitter, Brian Eckert, : https://www.westcoat.com/ and then this article pops up today.