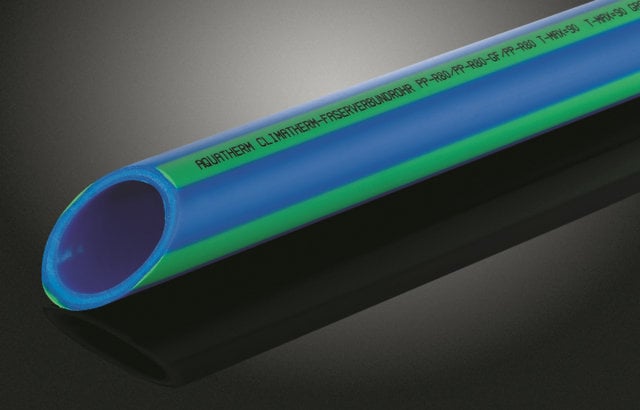

Craft brewers across North America are incorporating Aquatherm polypropylene-random (PP-R) piping systems throughout their facilities and brewing processes. Aquatherm offers numerous benefits compared to metal and many other plastic piping systems, including being the first piping system in North America to directly contribute to LEED v4 credits. PP-R is much lighter than metal, will not corrode or scale, is connected by virtually leak-proof heat fusion, will not leach any contaminants into the fluids that it carries, has a 60-year lifespan and is fully recyclable.

An important application of Aquatherm pipe in breweries is in glycol cooling systems. Jim Paschal, P.E., LEED AP, Aquatherm’s chief technology officer, noted that breweries typically run their product cooling systems at a lower temperature than would be used in many other applications.

“[Breweries] have a lot of heat they need to remove in a fairly short amount of time,” Paschal explained. “These low-temperature systems require glycol or another antifreeze.”

Aquatherm pipe is an ideal choice for glycol systems because the chemically inert PP-R pipe has a very high resistance to the chemicals in the antifreeze. In a properly designed and installed system, Aquatherm PP-R pipe will transport glycol for decades without any degradation in strength or performance. In addition, it provides better thermal insulation than metal pipe.

“All of that adds up to Aquatherm pipe providing better, more efficient operation of the system in glycol applications,” Paschal said.

Other benefits of using Aquatherm in breweries include:

- Fusion outlets allow for inexpensive and easy system expansion. These allow branch lines to be installed when the pipe is already in place. The pipe is simply drilled into with a specially designed bit that removes the PP-R material and the fusion outlet is welded into the drilled hole. They are typically less expensive than tees.

- Aquatherm also offers an exclusive hot tap tool that allows brewers to easily add a new line or a new fermentation tank without shutting shut down the cooling to the rest of the brewery.

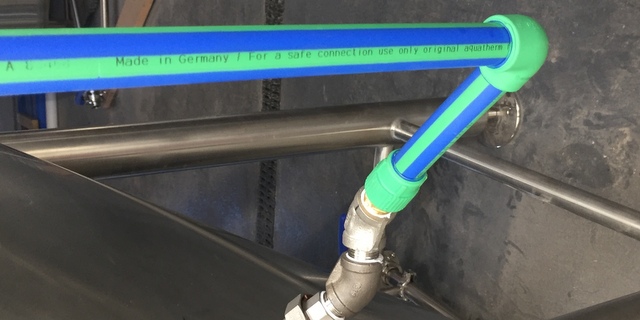

- Aquatherm’s fusion welding process is quick and easy, it introduces no additional materials or any contaminants into the system, and it yields a very smooth-flowing inside diameter of the pipe. And, as no two fermentation tank installations are exactly alike and the world is not made up of perfect angles, fusion welding also provides flexibility to accommodate minor angular variations during installation.

- Despite the ease of fusion connections, Aquatherm is still a craftsman’s system. While a level of plumbing/pipe fitting expertise is necessary for a proper installation, many brewers have completed the Aquatherm training and partnered with a local installer to save money on the installation and future expansion and maintenance.

- “These are additional benefits, above and beyond all the other advantages that come from using polypropylene in breweries,” Paschal said. “I think that’s why we’re seeing such a huge interest in the Aquatherm product line across the craft brewing industry.”

Aquatherm will exhibit its PP-R piping systems in Booth #3000 at the Craft Brewers Conference and BrewExpo America 2018 in Nashville, May 1-3. Large and small brewers from coast to coast are embracing Aquatherm pipe for applications such as glycol lines, domestic water, heating and cooling, reclaimed water and CO2 lines.

Leave a Reply

You must be logged in to post a comment.