Hey, the Craft Brewers Conference and BrewEXPO America is right around the corner, taking place in Nashville from April 30 to May 3. The trade show floor gets bigger and bigger every year, and to save you some time, we reached out to the exhibitors for a sneak peek of what they will be showing off at their booths this year. Stay tuned for the entire “What to see at CBC 2018” series over the next few weeks, plan out your expo hall path and save some of that walking around time for drinking.

Beerbev virtual reality brewery planning platform

Booth: 2900

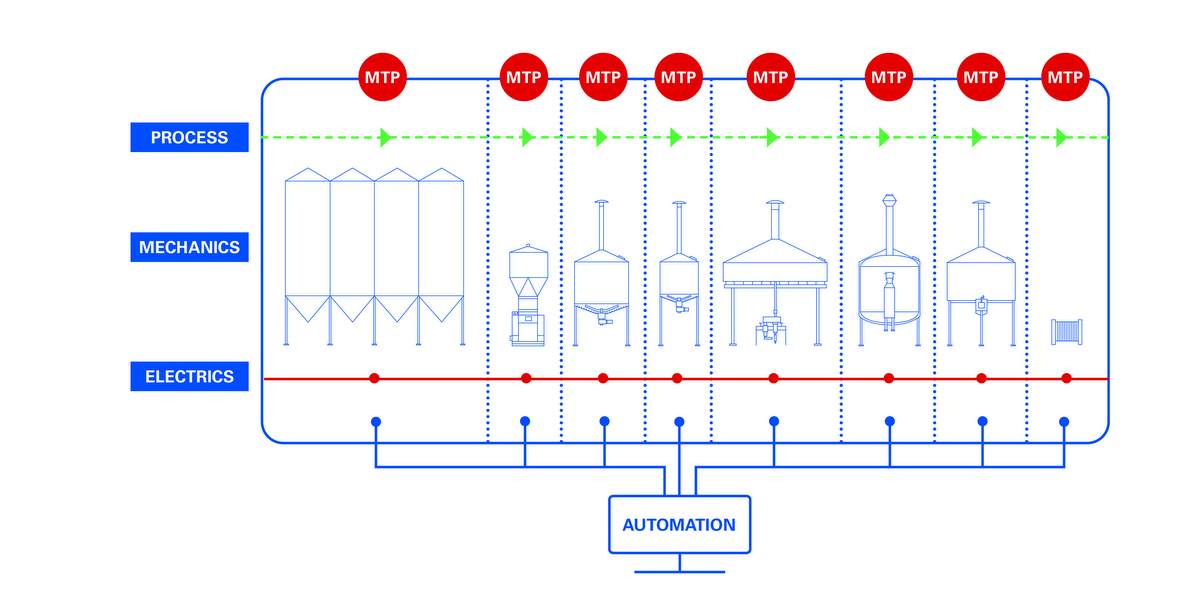

BeerBev has combined its experience and expertise in brewery engineering and planning with the latest in augmented reality technology to create a platform that allows the user to fully experience their brewery design. Utilizing Unicorn 4.0 allows you to become fully engulfed in the design of your brewery. BeerBev’s holistic project approach coupled with innovative technology will ensure that all areas (process, filling and packaging, utilities, civil work and automation) are considered from day one of the planning, leading towards customized solutions that optimize CAPEX and OPEX. Modernizing and/or optimizing your brewery doesn’t have to be a big transformation — small adjustments can have a big impact on operational costs and the bottom line. By understanding all angles of the entire value chain (process, technology, automation and civil design), Beerbev helps identify hidden savings, potential synergies and ensure that all existing interdependencies are considered to provide you with customized solutions that will improve your bottom line.

ZIEMANN HOLVRIEKA’s 50-bbl solutions

Booth: 344

At this year’s Craft Brewers Conference in Nashville Ziemann Holvrieka will showcase its comprehensive product and service portfolio, which is particularly interesting for craft and creative brewers. The focus of the exhibition at booth 344 is on a brewhouse solution, specially developed for the requirements of the North American craft brewers. This solution is offered from a cast-out wort volume of 50 bbl. In addition, ZIEMANN HOLVRIEKA will present its innovative brewing process, OMNIUM, which celebrated its world premiere last year and which represents a completely new way of wort production.

Standardized and technically reduced brewhouse modules restrict the flexibility and thus the creativity of the brewmaster. Consequently, ZIEMANN HOLVRIEKA offers all services and current brewhouse innovations, such as SHARK, LOTUS, COLIBRI for plant sizes from a cast-out wort volume of 50 bbl. For the craft brewer, this means: an energy and yield optimized plant with the highest level of flexibility and quality in what is the essential — the brewing process. Last but not least, the ZIEMANN innovations already provide the infrastructure needed to convert the brewhouse or later even the complete brewery to renewable energy sources.

The second focus of the exhibition is on OMNIUM, a completely novel brewing process. Here, the brewhouse tasks are divided into subprocesses, which are treated individually and, by subsequently combining partial flows, finally completed in an optimal way. The core component and centrepiece of OMNIUM are NESSIE, a separation and extraction system, a fractional wort boiling and hop isomerization as well as the wort saccharification with malt enzymes. Significantly shorter process times, more flexibility and higher raw material yields are the result of OMNIUM. The process also has a positive effect on the quality parameters of the wort, which accelerates the fermentation and increases both the capacity of the brewhouse and the cellar.

Mobile Hop Module from Paul Mueller Company

Booth: 800

Paul Mueller is introducing two new innovative pieces of brewing equipment at CBC this year. One, the Mobile Hop Module aims to revolutionize safety and ingredient usage around hop infusion. Mueller has already created hop-dosing vessels for either hot or cold side applications, now the Mobile Hop Module works on both sides and handles all manner of spices and botanicals. The design is a motor-free solution that employs fluid flow to harness the essential oils and resins in hops and adjuncts while mitigating the risk of shear damage. The removable screen design allows for multiple screens that can be used with cone or pellet hops as well as spices, fruits and more. Versatile for use in both the cellar and the brewhouse, with casters that allow the vessel to move throughout the brewery. With safety top of mind, the Mobile Hop Module eliminates the need to access the top of the fermenter for dry hopping and it allows you decreased ingredient usage, while achieving the same or better sensory results.

Here’s an interactive 3D preview of the Mobile Hop Module.

If better taproom serving options are on your shopping list, you don’t want to miss the Serving Beer Tank. These unique serving tanks with bag inliners have been used all over Europe for decades and legacy beer brands and small micro-breweries alike are integrating them into their distribution models for fresher beer and cost savings. The cutting edge technology used in these tanks allows them to hold high-strength bag inliners, creating a self-cooling, bag-in-tank system that can be used directly in the taproom.

IDD Process and Packaging with a new Mobile Hopback, mash filter

Booth: 2400

This year, IDD Process and Packaging will be returning to the 2018 Nashville CBC and featuring its new Mobile Hopback, the latest version of the Squire Plus 2 and the newest version of the HEBS mash filter brewhouse that features a manually operated Nano 5 Hl (4.2-bbl) system with similar efficiency to its larger automated models.

Braukon custom, turnkey brewery creation

BrauKon delivers turnkey brewery systems dedicated to craft breweries worldwide. Its 30 master brewers and engineers plan, design and build top-quality brewery systems that are highly flexible, economically efficient and profitable without compromising on beer quality. From upgrade, modernization to turnkey breweries — BrauKon is your competent partner. The process of your entire project, from planning to realization, lies with only one partner. BrauKon turnkey breweries are tailored to meet your individual requirements. The company’s technical center — BrauKon BrauTechnikum — is the ideal location for its individual custom-tailored training courses which optimally prepares you for the new technology of a BrauKon system. The company guarantees the value and reliability of its systems thanks to high-quality workmanship of first class components.

Della Toffola USA crossflow filter

Booth: #610

Della Toffola USA will feature its DE-FREE CROSSFLOW FILTER FOR BEER (CFK-B) with award-winning Ceramic Membrane technology, as well as an FSB Filter, an A4 and a large A6 Plate and Frame Filter. Experience in ceramic membrane crossflow filtration has led Della Toffola to the development of its new CFK-B series filters designed to filter beer for small, mid-sized and large breweries. Della Toffola CFK-B filters are suited for use with all types of beer, even those with special characteristics that are hard to filter. Excellent organoleptic stability and exceptional high clarity of the filtered product are ensured. Just one filtration cycle is enough to pass from the fermentation tank to bottling for time savings that boost brewery output. All filters are fully automatic and come with touchscreen and user-friendly software, and they require no supervision during operation. Benefits of the CFK-B Ceramic Membrane Crossflow Filter include:

- The quality of the filtered product

- Guaranteed filtered product organoleptic stability — lowest as possible DO pick up

- Minimum OPEX and cleaning costs — waste-free production

- Low environmental impact and energy savings

- Improvement of workplace and operator safety

- Automation of the filter process — no supervision is required

- Ease of use

- Possible to run the filter remotely

L.J. Star created the first LED sight-glass light for craft brewing

L.J. Star Inc. introduced the LumiStar1000, the first LED sight-glass light designed to give brewers a better view of their processes and a green-energy alternative to conventional halogen lights. Mounted over a sight glass on a mash tun, brew kettle, fermenter, bright beer tank or serving tank, the new light gives brewers a better view of processes with light that is two times brighter than a typical sight-glass light. The new luminaire, which is capable of outputting 1000 lumens at full brightness, produces twice the light output of a standard 100W halogen luminaire with less energy and heat. It consumes less than 11W of power at full brightness, one tenth the energy versus a traditional halogen light.

The stainless-steel washdown-rated luminaire is equipped with a total internal reflection (TIR) lens with a 23 beam angle, which is ideal for vessel illumination through a sight glass because it maximizes light output by keeping output loss to less than 5 percent. Its cool-white (5,500K color temperature) LEDs maximize visibility in stainless-steel vessels. Unlike an ordinary light, the LumiStar1000 has built-in microchip intelligence. The “smart” design allows brewmasters to choose from four modes of operation: flashlight mode, timed mode, continuous mode and an optional dimmer mode. Its unique technology makes possible continuous mode, which is not available with other lights in its class. The LumiStar1000 is designed for cool operation with temperature-based current limiting and automatic dimming. An over-temperature shutdown function enhances workplace safety.

Hector Aguilera says

Rodrigo Nogueira