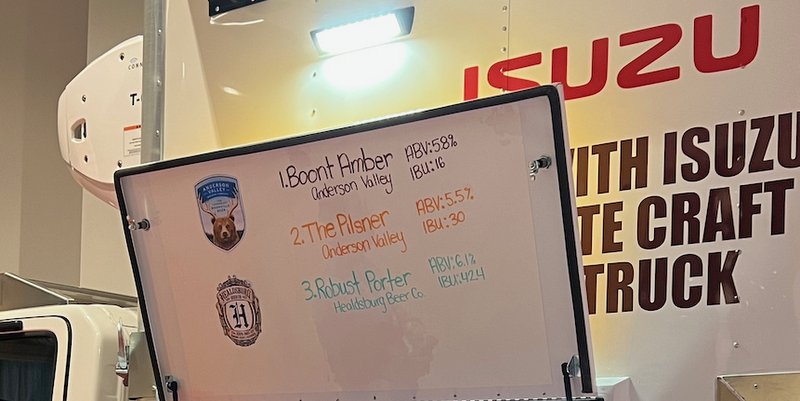

Craft beer customers and retailers ask every day what’s hot and what’s next? The answer is often the seasonal brews and one offs that brewmasters develop to satisfy the craving for new and different from the local or regional craft beer market.

The problem often encountered by these smaller breweries is the economics of can printing, which is based on trailer-sized volume orders of 200,000 cans and a limited number of colors that can be printed on a can. These factors make it difficult to print short runs requiring fast turnaround. Fortunately, shrink sleeve labeling, where brightly printed thin gauge film sleeves are applied over cans and then form fitted through a heat tunnel process, delivers an ideal packaging solution.

The printed can supply chain is stacked against low volume orders

Printed can economies of scale are based on a tradition of long runs of a few products. Can printing is adapted to the needs of the big buyers, with massive packaging facilities and equally large storage and distribution centers. In this mega environment, new beers are planned many months in advance and fast turnaround of art work has no real value. Graphics are basic and utilize only a few colors. To be fair, that’s how the can manufacturers are set up with their suppliers and how they make their money. Even for the craft brewery, the economy of a 200,000-plus can order can’t be beat for year-round beers in terms of unit cost.

This supply chain simply won’t work for the limited edition offering of the regional craft brewery. So, the problem remains: How to economically package seasonal beers and one-offs? Bottles with paper labels are one way to go, but the shelf life with bottles isn’t as good as cans. Blank cans with paper labels will work, but the appearance isn’t that appealing.

Craftpac is an expert in shrink sleeve labeling

Craftpac is the brainchild of husband and wife duo Roger Davis, co-founder of Red Hare Brewing Co., and Bertha DiMarco-Davis, managing partner of Craftpac (website under construction). Both companies are located north of Atlanta in Marietta, Ga. Roger wanted to solve the problem of packaging short run beer and attended BrewExpo America to see what the market was offering. He was intrigued by the possibilities of shrink sleeve labels — a type of inexpensive plastic film sleeve that can be printed using a high number of colors and slipped over a blank can by a shrink sleeve application machine. Following application, the sleeved can travels on a conveyor through a steam-heat tunnel where the film shrinks and hugs the can like a glove.

“I was impressed with the fact that the vibrant graphics and the form-fit fool the eye into thinking the can is printed with those colors,” Roger said. “I thought that if Red Hare Brewing needed short runs then other brewers would as well. I saw a new business opportunity — a shrink sleeve labeling service — and discussed it with Bertha.”

Bertha DiMarco-Davis had spent her career in logistics management and had a wealth of contacts in the canning industry. “My background was a natural fit for the kind of business Roger envisioned,” she said. “We began work on a new labeling business — Craftpac, LLC — and opened our doors in 2016.”

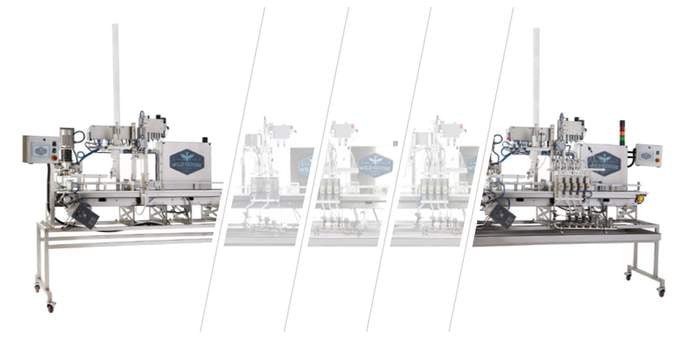

Axon, a product brand of ProMach, and its line of EZ shrink sleeve applicators intrigued Roger and Bertha when they started looking for the anchor piece of equipment for Craftpac. “We were impressed with the quality and ease of use of Axon label applicators,” Bertha said. “We also liked the fact that Axon offers application specialists for the craft brewing industry and develops technology specifically for craft beer canning lines. It shows their commitment to our industry.”

Craftpac purchased an Axon EZ-130 applicator and steam heat tunnel. The EZ-130 is rated at up to 65 containers per minute. Other models of the EZ line apply sleeves at rates of up to 150 containers per minute with higher speeds available from Axon’s Aurora and SLX product lines. Craftpac’s team engineered and built aids for de-palletizing blank cans and palletizing labeled ones.

Bertha also formed relationships with local film converters. Shortly after the business began, Roger and Bertha introduced the concept of shrink sleeve labeling and Craftpac’s services to Carly Wiggins, marketing and sales director for Southbound Brewing Co., in Savannah, Ga.

“We were impressed by the graphics, the fast turnaround, and the option to order in small quantities, so we gave Craftpac a try,” said Carly. “The process was as advertised and now all our seasonal and one offs feature shrink sleeve labels. In fact, when I travel, I take sample cans with me to give retailers the opportunity of judging the visual appeal of our packaging for themselves.”

The process is seamless

Southbound Brewing Co. has a long-term relationship with a local artist who designs the brewing company’s labels. Southbound’s brew names are music related and feature dazzling graphic elements. After Carly’s team has the design for a new label, the file is emailed to Craftpac. Bertha and her team provide samples.

“We can have new cans arrive at our loading dock about four weeks after we send the initial artwork,” Carly said. “In a crunch, Bertha tells me, she and her team can turn around a job in two and a half weeks.”

The unit cost for a shrink sleeve labeled can is higher than pre-printed, but brewing companies order only the quantity needed and have products on store shelves weeks before pre-printed cans would even arrive. Plus, the cans are in and out, quickly solving any storage space issues for breweries.

“Shrink sleeve labels give Southbound the flexibility and cost effectiveness that we crave, and these labels appeal to the retailer’s desire to have something new to offer customers,” Carly said.

For those located outside of the Craftpac Southeast regional service area, Axon assists breweries and mobile canning units with both new and refurbished EZ labelers.

Ed Farley is the southeast regional sales manager for PE Labelers and Axon Shrink Sleeve Label Applicators, both product brands of ProMach. Farley has extensive experience in the packaging industry in both domestic and international sales. His focus has been primarily on shrink sleeve label application machinery sales. Farley is a graduate of University of North Carolina at Chapel Hill.

Leave a Reply

You must be logged in to post a comment.