With the passage of the Food Safety Modernization Act and the increase of standards in brewery inspections, brewers are looking to tighten up their sanitation and safety measures. To do so, many are incorporating color-coding plans in their facilities.

While color-coding certainly isn’t a new concept, food and pharmaceutical processors have used them for a while now, it is a newer trend in the brewing space and due to the customizable nature of these plans, it can be difficult to know where to start. While each brewery is unique, there are two main color-coding blueprints that most color-coding plans are molded from.

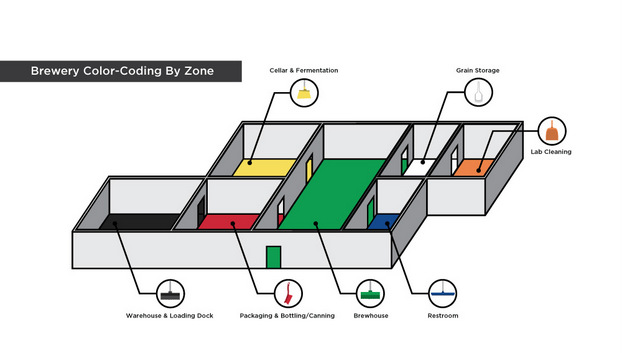

Color-Coding By Zone

Color-Coding by zone is the easiest plan to implement in a facility with defined areas. Here, you would designate a color to each defined area of your brewery (i.e. brewhouse: green, cellar & fermentation: yellow etc.). Once you have created this plan, you’ll want to replace all of your tools in each zone with color-coded, food-safe tools. This helps to ensure that a tool that shouldn’t come in contact with particular materials stays in its proper area, ensuring a safer environment that protects both your tools and equipment. Because it is recommended that you store these tools on designated color-coded racks, tools are less likely to be used improperly, go missing and are easily identifiable when the need for replacement arises. Due to the high traceability this allows, this measure can also help in the event of a recall.

Note that before you commit to a certain color you’ll want to ensure that you are able to purchase every tool needed in that particular color.

Color-Coding By Use

Color-coding by use is generally used in facilities that do not have strictly defined zones. In this model, you assign colors to the tools by the use they will have (i.e. product surfaces: white, product proximity surfaces: yellow etc). Common additions to this plan include a designated color for broken glass cleanup for breweries that bottle their product and additional colors for those with taprooms that serve food (i.e. a color for uncooked meat, a color for food ingredients that are common allergens).

All color-coding plans require extensive training and signage to ensure proper implementation and this is especially important with a plan such as this one where there aren’t easily identifiable “zones.” Make sure you take the time to draft the plan with all involved parties and implement thorough trainings and checkins with all team members.

Though it can be tempting to go very custom in your color-coding plan, it’s best to keep your plan as simple as possible — ensuring it is easily remembered and implemented by all at your facility. Consider forming your plan from the bones of the above approaches and reach out to a color-coding specialist with questions specific to your facility.

Adam Serfas is the owner and president of R.S. Quality Products. R.S. Quality Products sells color coded cleaning tools for food processors and pharmaceutical companies. It is a small, family run business with over 25 years of experience in the industry.

Jesse Allred says

The strategy of color-coding your brewery can improve not only your safety measures, but can make your manufacturing process smoother. Breweries really can be a dangerous workspace if safety doesn’t come first. With huge containers of boiling liquids, flames in the work environment, confined spaces, and all other hazards that come with brewing beer, it’s easy for brewery to go from fun to dangerous. If you’re looking for more information on brewery safety, and addressing the concerns that come with it. Check out this helpful article: https://blog.creativesafetysupply.com/brewery-safety/