Beer is the gift that keeps on giving the whole year (it’s not a membership to the Jelly of the Month Club). Yet the magic of beer actually comes from a fairly unmagical manufacturing process that relies on loads of science and equipment. The brewhouse and packaging hall are basically a warehouse of application-specific machinery — brew kettles, water tanks, mash mixers, wort chillers, lauter tuns, fermenters, compressors, heat exchangers, brite tanks, piping everywhere, rinsers, fillers, conveyors, accumulation tables, palletizers, depalletizers and eventually, after way more equipment than we mentioned, you get your six-pack of beer.

It’s an amazing Rube Goldberg-type process that’s really hard to fathom when you crack open that bottle of maple bacon Christmas ale, which tastes like it was made by elves and alchemy. But the true magic behind beer comes from crews of hardworking beer enthusiasts operating interesting equipment with innovative techniques. To celebrate some of those great beer makers and their cool tools, we reached out to some industry experts to ask about their favorites pieces of equipment.

From pasteurizers and carbonation systems to hop backs and brewhouses, folks from Yuengling to Steam Bell Beer Works picked some favorite equipment that’s helping take beer production to new levels of consistency and character. We’d like to thank all who participated in this equipment list. Hopefully, it’ll help other breweries consider new, mechanical ideas for a whole new year of production. They also make very thoughtful holiday gifts.

Barry-Wehmiller pasteurizer and a Paxton can rinser

Jennifer Yuengling, VP of operations

D. G. Yuengling & Son (Pottsville, Pa.)

Sustainability is one our priorities at our breweries, and we’re always seeking opportunities to reduce energy and resource consumption. In October 2017, D.G. Yuengling and Son Inc. completed a capital investment in its infrastructure of its Pottsville Brewery, known as America’s Oldest Brewery, with water savings technology. The brewery replaced its outdated tunnel pasteurizer with a Barry-Wehmiller Model H Pasteurizer that uses 4,300 gallons of water per day. The old pasteurizer used 40,000-50,000 gallons a day. Not only is this a very large reduction in water usage, but also a significant cost savings. If at all possible, we always try and use water twice before disposing of it. The 4,300 gallons of reclaimed municipal water is reused to rinse cans prior to entering the pasteurizer. This results in over a 1,000 percent savings in water usage and costs.

Another example of water savings is the brewery’s installation of an Ionizing Air System’s can rinser by Paxton Products, which replaced its water rinser system, also in October 2017. This waterless can cleaner reduces water usage by approximately 300 gallons per hour (3,000 gallons per day). The technology includes an Ionized Air Blower system that uses ionized air to blow out the cans and remove debris — thus, using zero water. The blower is run by an energy efficient motor and variable frequency drive that uses minimal electricity. Total water savings from both projects is 43,000 to 53,000 gallons a day. Energy savings includes reductions in the use of natural gas for heating and chemicals for water treatment in addition to the water savings.

Ziemann whirlpool

Martin Dickie, co-founder

BrewDog PLC (Ellon, U.K.)

Our Ziemann whirlpool is the gem of our brewhouse. It enables minimum turbidity in combination with shortest Whirlpool rest periods because of its unique design: The conical bottom, tangential inlets and different side and bottom outlets do a superior job in separating the trub from the wort. With this Whirlpool we get even the last drop of wort out of the trub, which means significantly higher yields. In addition to that, it’s perfect for us because it’s suitable even for extreme conditions like when brewing our high gravity beers. No matter if it’s our Prototype double IPA with 60 bitter units or our Hardcore IPA with 150 bitter units, there is always a compact trub cone in the center, which doesn’t collapse when the wort is strained. All in all I’d say that the vessel geometry and the resulting flow conditions as well as the arrangement of the wort outlets are the essential parameters for the proper functioning of a Whirlpool — and I’ve not heard of any performing better than the one I bought from Ziemann.

Inline carbonation system

Ryan Crisp, head brewer

AleSmith Brewing Co. (San Diego, Calif.)

One of our favorite new pieces of equipment is our inline carbonation system. As most small breweries are painfully aware, carbonating beer with a carbonation stone takes hours, holds up the production process, increases residence time, and adds to the potential for microbial infection if the stone is not cleaned correctly. Being able to carbonate inline has allowed us to carbonate the beer as it leaves the centrifuge, so the beer is within specification immediately. This means that we can have the beer centrifuged, carbonated and packaged within a single shift. This allows us to turn over our bright tanks in a matter of hours, or even bypass them and package directly from the carbonation system, meaning less downtime and less capital expense on equipment in the long run. Our sensory panel has also noticed a marked improvement in the aroma of our beers. Instead of a carbonation stone pushing aroma compounds into the tank headspace, the gas is diffused into the beer immediately. The result has been an increase in hop and malt aromatics and a more desirable finished product.

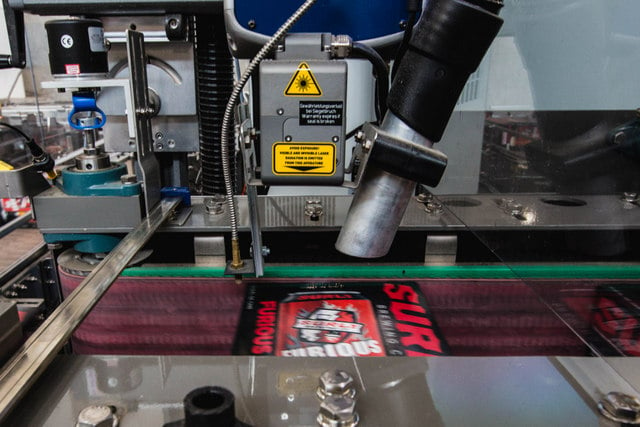

Domino lasers for use on packaging and bottling lines

Will Crosby, packaging manager

Surly Brewing Co. (Minneapolis)

Lasers are cool. Han Solo had lasers. Ergo: Lasers are cool. That’s not the reason Surly Brewing Co. has lasers, but it’s a terrific side benefit. Last year, Surly made an investment in product integrity by purchasing three Domino lasers for use on the packaging and bottling lines. Two of them for chipboard wraps, and one for glass etching. The goal for adding this technology was to uphold high quality standards and keep consumers informed.

When Surly made the switch from plastic rings to chipboard wraps in 2017, the lasers increased our ability to have clear, informative labels on all packaging. It expands our ability with exact date codes to add messaging to products such as IPA hop varieties or a simple “Thanks for drinking Surly.” The biggest impact will be on the bottling line. Prior to the laser, we were using white ink, which tended to smear or rub off. Starting in spring 2018, Surly will etch all bottles, eliminating those issues.

The brewery’s commitment to the new technology is such that the company now has a Laser Safety Officer, who trains other employees on the machine, demonstrates the proper safety techniques, and performs whatever upkeep is needed. However, the machines are, for all intents and purposes, maintenance-free, and they run forever. Bottom line: Lasers are cool, and they advance quality standards for our products.

10-hectoliter German decoction brewhouse

Andrew Foss, head brewer

Saint Benjamin Brewing Co. (Philadelphia, Pa.)

My favorite piece of equipment is not a newfangled toy or gadget, it is our 10-hectoliter German decoction brewhouse. We have had this brewhouse for about two years now, so it isn’t new, per se, but it is the key to making our best beers the best they can be. Before brewing on this fantastic piece of machinery, I was always a single infusion guy. Single infusion has its merits, and I don’t want to imply that you cannot make great beer that way. For me personally, learning how to brew using step and decoction mashes has changed my entire outlook on beer in general, and made me a much better brewer. This is the way most of your favorite Belgian, German and Czech beers are brewed.

You can brew pretty respectable versions of these beers with a single infusion, but it’s always going to be a compromise. A true Czech pils is usually brewed with a triple decoction (due to time constraints, we brew Pilsner Prosim with a step infusion and single decoction). Think about what that means. It means that you are threading together six different mashes using two vessels. It results in complexity and melanoiden development that you can’t get with a single infusion, no matter what. All that said, none of that matters if you can’t control fermentation correctly or can’t hit the temps you wanted with your mashing regimen. Most brewers, pro or amateur will tell you that single infusion is the way to go, and there is no need for step mashes or decoction. I have yet to get this advice from a brewer who has actually spent any time brewing on a decoction system, and I doubt I ever will.

Hop back

John Gillooly, brewmaster

Drake’s Brewing Co. (San Leandro, Calif.)

It was actually rather hard to cite a favorite brewing vessel; the mash tun is where all of the sciencey magic happens, and the kettle is its own port of science and mystery. But on consideration, I think my favorite piece of equipment is the hop back. The hop back is for special occasions, for when the spice of hops alone isn’t enough. Yes, yes it is called a back and was developed as a place to add hops, but we use it for more than that — it is for when we want to add extra spice, extra flavor, extra … whatever — whatever fun stuff we might get in our (collective) heads.

It is on my mind right now as we just brewed Tree Beer, an IPA originally brewed with a cut-up Christmas Tree chucked in the kettle. And credit to Rodger Davis of Faction Brewing for the concept and brew — before he opened Faction he came to Drake’s to make Tree Beer and left us the beer to make every year. We adapted Rodger’s idea to a more elegant execution, and now instead of throwing a tree in the kettle (which is hard to remove!), we line our Hop Back with resinous hops, spruce tips (just the tip!) and Juniper branches and berries.

The hot wort sprays over the pile of vegetation and infuses the beer with amazing flavors and aromas. We’ve also used the hop back to make beers with dried and edible flowers, herbs, spices and other botanicals. Honestly, it is rather a shame that we only use it for special occasions — it does an excellent job of infusing an extra layer of hop flavor and aroma into beer — but it slows us down and is a royal pain to clean. Still, my favorite — it always means something extra fun is happening in the brewery.

Alfa Laval’s Brew-350 centrifugal-separator

Ryan Pappe, head brewer

Portland Brewing Co. (Portland)

For many breweries, clarity in the finished product is an important way to show the high quality of the beer before the consumer even gets a sniff or taste. The ugly truth is that filtering beer can seem to be a no-win situation, stripping out some of the flavors and aromas that costly ingredients contributed while simultaneously introducing oxygen through pumps and seals that speed up the staling process. After years of dealing with the frustrations of wrangling our old beat-up filter to properly clarify our beers, we finally purchased our new Alfa Laval’s Brew-350 centrifugal-separator and could not be happier with the results. After our beers pass through the centrifuge, the flavors and aromas are more intense, the clarity is sparkling and oxygen levels are at all-time lows.

On top of the improvement in beer quality from using this separator, we have cut processing times nearly in half. Clarifying our beer is now a quick and painless process that frees time for more rewarding pursuits. And unlike the old filter, it runs steadily, quietly and with minimal complaints. It is my favorite new piece of brewery equipment, and it is no competition.

ATP meter

Brad Cooper, head brewer and owner

Brad Cooper, head brewer and owner

Steam Bell Beer Works (Midlothian, Va.)

Several months back we purchased an ATP meter as part of our QC program. At nearly $1,500 it was initially a rather steep investment but it paid for itself within the first month. One of our brewers hadn’t properly cleaned a tank and the ATP meter was able to alert us to the contamination prior to filling it with wort (that cost way more than $1,500 to produce). We have since written it in to our operating procedures that each tank must be swabbed and tested before filling.

Ska’s Shortbus mobile depalletizer with conveyer and rinse cage

John Cochran, founder

John Cochran, founder

UpCountry Brewing Co. (Asheville, N.C.)

Our new Shortbus mobile depalletizer with mobile conveyer and rinse cage from Ska Fabricating is an awesome piece of machinery. Before having it installed, we ran our first batch of cans in what I will call the old-fashioned way: Two employees wearing sterile gloves took the cans from the pallet, dunked them in a cooler full of sanitizer, and then placed them on the canning line. Luckily that was a quick 3-hour initial run and we didn’t have to do that for a full day! I can say with absolute confidence that not only does the Shortbus depalletizer save us on labor costs, it also leads to far fewer damaged cans and less chance of any type of contamination occurring compared to when each can was being handled by a person. The Ska depal rocks. We financed it through Brewery Finance, which made getting the equipment super easy.

Starrett No 599 height gauge planner shaper

Sebastian Wolfrum, executive brewmaster

Sebastian Wolfrum, executive brewmaster

Rocky Mount Mills (Rocky Mount, N.C.)

My favorite new tool is this thing called a height gauge planer shaper, in my case, a Starrett No 599. At first sight, it looks like something that was used to navigate ships across the oceans a long time ago. It could have some use in that as this planer shaper is a tool to adjust two parallels. The parallels where this is most helpful to us canning brewers is for accurate height adjustment to a seamer head where the parallels are the bottom and the top of the can as they relate to the base track of the seamer unit and its seamer head that engages with the can and the loose lid upon entering. Getting this height right is important for a perfect double action closing of the can as well as keeping the wear and tear on the seaming head to a minimum. I can only suggest trying one if you do not already have one with your line.

Leave a Reply

You must be logged in to post a comment.