The Craft Brewers Conference and BrewExpo America is the No. 1 event of the craft beer year (April 10-13), and we want you to be ready to see all of the cool new stuff on the trade show floor. We asked exhibitors to tell us what they will be showing off, and we turned those submissions into these handy CBC previews. See you in D.C.

Upgrading your packaging process isn’t just about using better equipment. Incorporating the right machines and the right layout could have a sizable impact on your production efficiency, which also maximizes the time of your employees — less mindless tasks means more time for work that evolves the business.

If this all sounds like something you should think about, the CBC is the perfect place to get started. Here are a few of the booths that should be on your to-do list.

Bottles

O-I | Booth 401

Before getting into the heavy machinery, make sure what you are filling is top of the line. For more than 100 years, O-I has been delivering safe, sustainable, pure glass packaging and prides itself on combining its glass design and manufacturing expertise with an understanding of craft brewers’ needs.

O-I beer bottles are made for exceptional handling and filling performance, which means customers can expect bottles that perform well and look great. O-I is a large company, which allows it to serve the unique needs of breweries large and small by offering low minimum orders, printed cases, credit card payment, a stock inventory program and custom bottle design services.

“We will be showcasing our growlers, which provide brewers with a simple way to send their products home with customers, as well as our Artisan and extended bottle collection that come in a variety of shapes, sizes and colors,” O-I told us via email. Call Melissa Kimball 419-280-0503 to schedule a booth visit.

Depalletizers

Ska Fabricating | Booth 3901

From depalletizers to conveyance to packaging line design, Ska Fabricating was one of the first manufacturers specializing in small footprint depalletizers. Chances are you have seen one of Ska Fab’s machines in a brewery near you. By making the slightest bit of automation accessible and affordable, Ska Fab’s innovation has revolutionized the way craft brewers are packaging their beer; so well in fact, other manufactures are starting to follow suit.

As many small craft brewers typically do, Ska Brewing’s Matt Vincent was hand-feeding cans into his own canning line when he thought there had to be a better way. When Vincent built the first depalletizer, it was fabricated out of pallet racks and a garage door track. Now five years (and many improvements) later, Ska Fab continues to manufacture small scale packaging equipment for craft brewers, making their equipment ideal for any bottling or canning line. Ska Fabricating is located in Durango, Colo.

At the CBC, check out its flagship product Can-I-Bus, the original slim profile can depalletizer. For those into bottles, they will also have their low-level, bulk glass depalletizer, the Snodgrass.

GR-X Manufacturing | Booth 4141

GR-X Manufacturing from Grand Rapids, Mich., specializes in providing bottle/can depalletizing equipment for the beverage, consumer products and brewing industries. With solutions ranging from manually operated all the way up to fully automatic, GR-X Manufacturing likely has an equipment configuration available to meet your needs and budget.

For 2017, the company will be exhibiting its manual full pallet can depalletizer — a safer, more efficient and cost-effective means of unloading empty cans onto your filling or decorating line.

Filling

Leibinger | Booth 2119

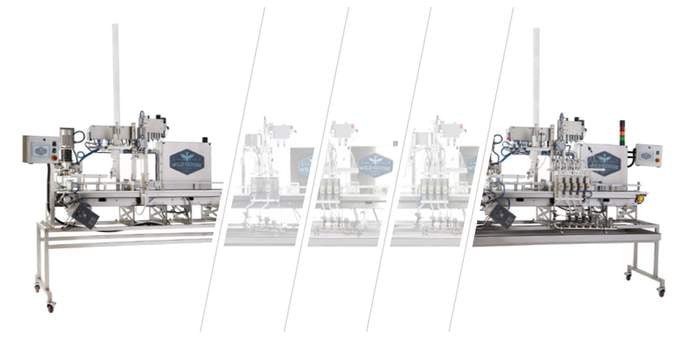

Many of you will be in need of a machine that takes up a small footprint but is still packed with cutting-edge technology. For more than 100 years, Germany’s Leibinger has been designing and manufacturing small and medium-sized rotary bottling, canning and transvasion machines for international customers.

All machines are 100 percent made in Germany, but the company has service partners throughout the United States, so no worries on stuff like spare parts, consulting and planning for new acquisitions through commissioning and maintenance. Leibinger also offers turnkey solutions for packaging lines, whether it is a can or bottle filling.

The company’s newest creation is a MULTIMA counter-pressure filler that can handle both bottles and cans. You’ll need to stop by booth 2119 to see it.

Packaging

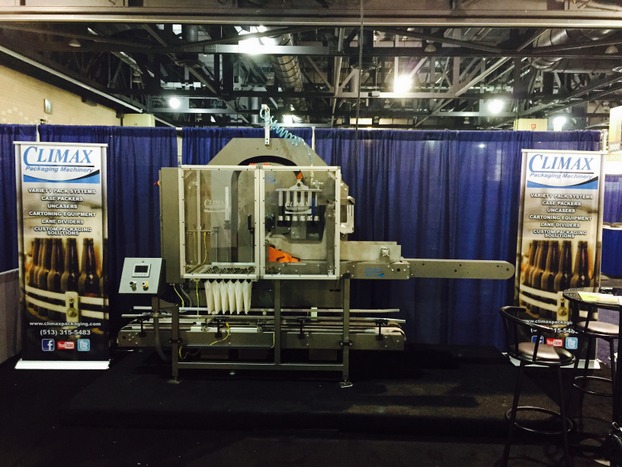

Climax | Booth 2119

But wait, there is more at booth 2119. Climax Packaging Machinery has partnered with Leibinger this year for CBC. The Leibinger/Climax booth will be showcasing a can filler and a bottle filler that is integrated with a Climax Strate Line case packer. The goal is to show how your entire process can be aided with automation.

The Climax Strate Line has a small footprint and is one of the most affordable soft case packers on the market. Why try to keep drop packing your beer or pay people to load it by hand? The Strate Line softly sets your bottles or cans within one-fourth an inch of the bottom of the case. This reliable and proven soft packing method greatly reduces breakage and costs on your packaging line.

Also, Climax has a CBC Special: Guaranteed four-month delivery.

Econocorp | Booth 3435

Econocorp will be displaying its new multi-purpose Spartan can packing machine. This machine has the ability to package loose cans into both a full display case of any size and a 24 count tray. The machine also has the ability to collate and load ringed 4- and 6-pack cans into a tray. Previously separate machines were needed to accomplish both tasks, but the newly designed Spartan, being debuted at this year’s show, has the ability to handle all of your end of the line beer packaging needs on just one machine.

A little bit of everything

Barry-Wehmiller | Booth 3508

No matter the container, when it comes to packaging solutions for breweries — palletizing, de-palletizing, conveyers, seamers, fillers, labeling, cartoners and so much more throughout the line — Barry-Wehmiller (BW) draws upon more than 130 years of experience. And four of the 12 companies under its banner — Accraply, BW Container Systems, Pneumatic Scale Angelus and Thiele Technologies — are uniquely positioned to provide a wide breadth of knowledge, technology and service for the beer industry.

Here’s what you can explore under that BW booth banner this year.

Can labeling. Minnesota-based Accraply will exhibit its craft beer can labeling system which includes the GrahamSleevit SLF Labeler, a perfect fit for smaller breweries canning smaller runs of product.

Can seamer. Pneumatic Scale Angelus’ new CB50 can seamer, based off their well-established high speed seamer design for larger scale operations, will also be on display. The CB50 will seam up to 50 cans per minute and can be paired with a PSA filling option or any carbonated beverage filler of the customer’s choice. Other filling and seaming systems can be retrofitted with the CB50 seamer.

Cartoners and case packers. Barry-Wehmiller companies also offer solutions for the front and end of the packaging line for canning or bottling. Thiele Technologies can provide automatic cartoners, case packers, case erectors, loaders and wrappers that are perfect for packaging brewery products and beer in a variety of case sizes and types.

Palletizing and conveying. BW Container Systems offers palletizing, de-palletizing, conveying, pasteurizing and robotic solutions to breweries of all sizes. Oscar Blues Brewery recently added BW Container Systems palletizers to its Colorado and North Carolina facilities, which also uses Pneumatic Scale Angelus can seamers.

Scott Smith, director of Global Business Development and Strategic Marketing for BW Container Systems summed up Barry-Wehmiller’s beer capabilities: “We’ve taken the technologies that we’ve provided for the brewing industry for 50 years and put them in a format that makes sense for craft brewers.”

Leave a Reply

You must be logged in to post a comment.