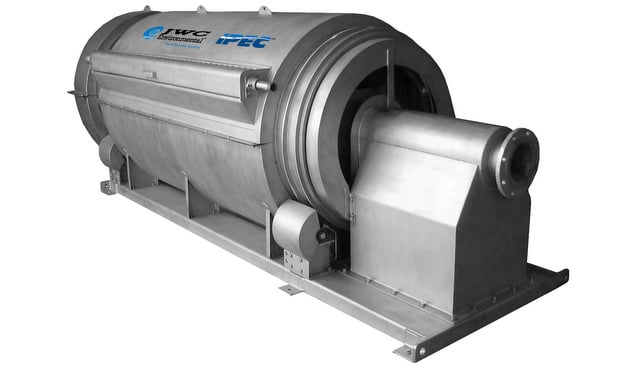

Industrial wastewater debris comes in all shapes and sizes — and so do pretreatment screening systems. There are four key aspects of wastewater engineers can consider to determine the right screening product for a specific industrial application.

Industrial wastewater debris comes in all shapes and sizes — and so do pretreatment screening systems. There are four key aspects of wastewater engineers can consider to determine the right screening product for a specific industrial application.

1. Type of wastewater contaminants

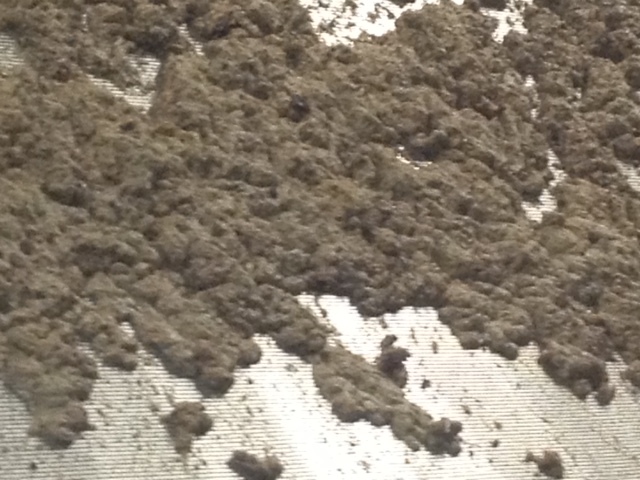

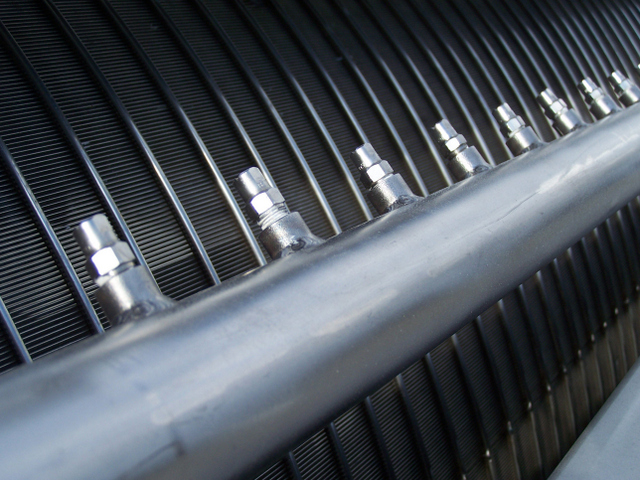

Understanding what contaminates are in the wastewater is critical in selecting the proper screen and will heavily influence the screening efficiency. Some variables to consider are the size of particulate and particle size distribution; shape of particles such as granular or striated; whether the particulate is soft or hard, organic or inorganic and whether particulate has a “stickiness” that will cause it to adhere to the surface of the screen.

The presence of FOG (fats, oils, grease) is also an important consideration in screen selection. This is a common byproduct of many industrial applications and FOG in the waste stream will promote the filling of the screen opening. Proper steps in the design of the pretreatment screen can deal with most of these variables.

2. Flow rate

Screening decisions should be made based on the maximum flow rate possible for optimal effectiveness. Engineers should identify variations in the industrial process that can cause significant changes in flow. Often some surge controls or equalization can be designed into the process to normalize either low or high flow conditions. Improper selection of a high-flow screen for a low-flow application can lead to problems as well, such as debris settling.

3. Solids loading

The screen selection will depend on the solids concentration (TSS) and percentage of solids that are captured or rejected. If the process is variable in both flow and solids concentration, then typically the screen selection is based on the point of maximum solids loading.

4. Treatment scheme

Understanding the complete treatment requirements will determine the selection of the type of screen unit and screening element. The screen determination will be a factor of the max size particulate that can be accepted at the succeeding stages of all individual treatments. It will also be a factor in the costs of disposal of the by-products of treatment and the cost or cost recovery associated with the screened materials.

Screen placement is also a consideration in the overall treatment system design. When installing screens at industrial plants, it is important to screen as close to the wastewater source as possible. This prevents natural breakdown of solids and makes it easier to screen out the solids from the waste stream.

For more info on industrial wastewater screening, check out Matt Brewing’s project here.

Bob McGowan, industrial sales manager at JWC Environmental, and Stacy Peshkopia, global product manager for commercial and industrial products at JWC Environmental.

Leave a Reply

You must be logged in to post a comment.