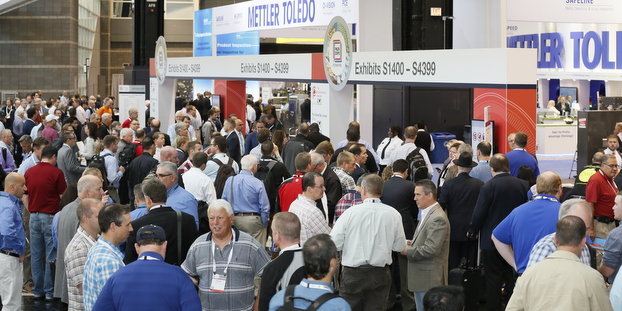

Manufacturers at every stage of the packaging line exhibited products targeted specifically at craft breweries at this year’s Pack Expo. The four-day event, which took over nearly all of McCormick Place from November 6-9, featured more than 2,500 exhibitors showcasing their machinery and packaging to some 50,000 attendees.

Just for craft

If you went to CBC in Philadelphia, you may have seen some of these new machines. The story at Pack Expo was not new machines so much as that corporations like Barry Wehmiller, Graphic Packaging, Hamrick and ProMach brought these machines to such a huge event. Even Krones, which did not bring its craft-sector machine, still displayed 6-pack Gumballhead and Alpha King baskets to associate themselves with craft beer.

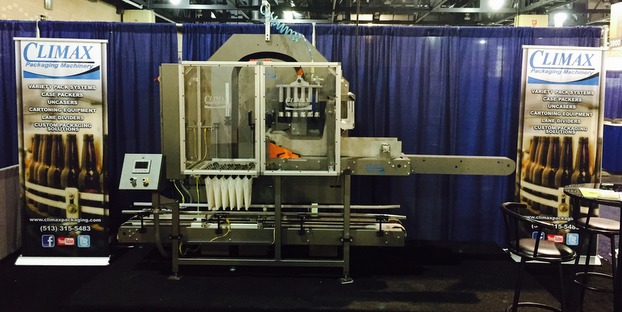

Over and over again I heard that manufacturers want to develop solutions for craft brewers looking to start packaging. That meant they were producing machines that did fewer tasks, with a smaller footprint, so the small brewer can start with just the equipment they’re ready for.

RELATED: Packaging on a budget: Four solutions your craft brewery should consider

EconoCorp offered a series of solutions that, according to Chuck White, were “ideally suited for the people starting out.” They emphasized their machines are simple, small and affordable and are thus good for the small-to-moderate-speed packaging line. White also emphasized that they could easily adapt their machines for formats such as variety packs.

Hamrick and Hartness were among a handful of case packing companies featuring a “pick and place” bottle packing machine. Typical case packers may drop the product from several inches and thus often have a degree of waste through breakage. The pick and place packers use various technologies to bring bottles as close as 1/16-in. from the case bottom before releasing them. There is a potential for significant waste-reduction and overall savings for an entry level price of about $100,000 for the Hamrick CP15.

Carleton Helical were among several companies offering ionized air rinsers as smaller, more energy efficient and more effective cleaning solutions compared to water systems. Connie McDermott touted their machine as “a very simple piece of equipment—compact and inexpensive.” Carleton’s setup begins around $1,000.

In-Line Packaging offered perhaps the most basic and economical bottling line solution. Shaped like a horseshoe, it has a footprint of about 10 feet x 12 feet and can be run with just two people. For about $97,000, the line features a labeler, rinser, 4- or 6-head carbonated filler and crowner.

Craft can-do

Easily the most common craft-specific machine was a can sleever. If a company was going to have a machine for the craft brewer, it was more likely to be a sleever than anything else — even if they were more focused on seaming or coding, for example.

Many companies, such as Axon and Accraply, took an existing machine and stripped it of unnecessary features so they could offer a low-priced, small-footprint, single-process option for the craft brewer. The Accraply Craft SLF sleeve applicator can label up to 80 cans per minute for a price of about $60,000.

Like several of the breweries I ran into at Pack Expo, Michael Gaesser of North American Breweries was checking in with existing partners and keeping an eye out for what’s coming next. He seemed pleased with all the attention to sleeving.

“This is going to be the big thing in craft,” he said. Corroborating the manufacturers’ pitches, Gaesser pointed to the cost-effectiveness of sleeves because a brewery can buy bright cans in bulk and make small print-runs of the labels.

The machines themselves all seemed pretty similar in functionality, and the space is pretty new. That means few companies felt the need to emphasize their points of differentiation. That leaves it to the buyer to compare price, speed and footprint to discern which makes the most sense for his or her brewery.

RELATED: The pros and cons of printing on cans vs. using can sleeves

Standout labelers

The same appeared true for the labels themselves, though a few companies stood out. Century Label touted its HP SmartStream Mosaic Software, with which a brewer can quickly create “hyper customized” labels. That is, a nearly infinite variety of labels can be created from one large design file such that any two cans coming off the line will be subtly different while retaining brand coherence.

In the area of adhesive labels, UPM offers its new VANISH film. VANISH labels appear virtually invisible but are still durable enough to allow for some dramatic use of shape, color and even texture on both bottles and cans.

Flexo Impressions showed me a wood veneer custom label they did for Peterson Brewing Co.’s Hard Cider that literally looked like a tree wrapping around the glass bomber. For breweries looking to distinguish themselves, custom and “invisible” labels offer a subtle but dramatic alternative to both paper and sleeves.

We have more Pack Expo insights coming from Brad Fruhauff later this week. Brad is a killer freelance beer writer who contributes to CBB. Check out his own site here.

Takehiko Nakahara liked this on Facebook.

Craft beer packaging trends spotted at 2016 Pack Expo https://t.co/brz8xUpaN8 via @craftbrewingbiz

@CraftBrewingBiz @BradFruhauff Pneumatic Scale Angelus has new 50 & 100cpm Filler/Seamer canning solution as well for anyone looking!

Craft beer packaging trends spotted at 2016 Pack Expo https://t.co/GpUlAtzOH0 #beer #craftbeer