Water is power. The world needs it. Water is also beer, which the world also needs. All breweries understand this, especially a brewery like Russian River Brewing Co., which literally gains its name, inspiration and flavor from that Russian River. In order to keep these standards of flavor quality and sustainability high as the brewery expands, it has turned to Cambrian Innovation, a biotechnology company solving critical resource challenges for the industry.

“Sustainable production is really important to us,” says Natalie, “and we want to ensure that we remain conscious of our environmental impact as we grow. The EcoVolt solution will cut our carbon and water footprints, ensuring that if we do choose to further increase production, we also give back to the environment.”

The Sonoma County craft brewery, famous for its strong IPAs, sours and, most notably, for its limited release Pliny the Younger, will be the first to install Cambrian’s EcoVolt MBR as a standalone solution.

RELATED: University of Colorado Boulder designs natural battery electrodes from beer wastewater

What is the EcoVolt MBR?

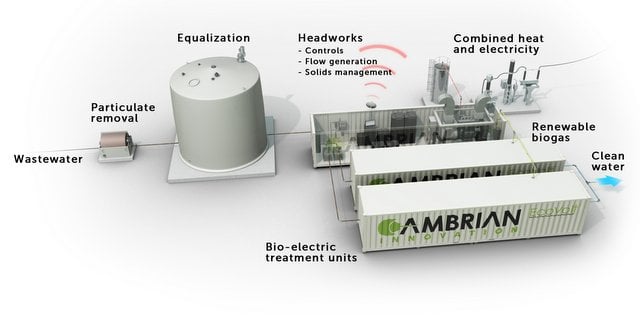

Commercially launched in 2015, the EcoVolt MBR is a modular aerobic digester that efficiently removes 99 percent of contaminants from industrial wastewater, producing water suitable for discharge or reuse. The system is designed to be used independently or in conjunction with Cambrian’s flagship EcoVolt Reactor for energy-efficient wastewater treatment and water reuse.

Like Cambrian Innovation’s other EcoVolt products, the EcoVolt MBR is fully automated and generates continuous feedback on system performance, enabling real-time control and minimizing operator oversight.

Expanding Russian River

Russian River owners Natalie and Vinnie Cilurzo announced plans to build a second brewpub in Windsor, Calif., earlier this year. The Windsor facility, slated to open in the fall of 2018, will allow the brewery to nearly double their annual production and is designed to accommodate future expansion as needed.

The brewery’s EcoVolt solution is also designed for future expansion. Beyond the EcoVolt MBR, the facility can accommodate additional EcoVolt Reactors, matching treatment to increased production and generating renewable energy onsite. This feature was particularly compelling for Co-Founder and President Natalie Cilurzo.

“From an operational standpoint, it was extremely important that we be proactive about managing our wastewater at the new facility and lay the groundwork for future water reuse.” added Vinnie Cilurzo, co-owner and brewmaster. “We started evaluating solutions early in the planning process. Cambrian’s EcoVolt product suite offers the most efficient and sustainable solutions on the market.”

The EcoVolt MBR at Russian River’s new brewpub will treat 100 percent of the brewery’s wastewater flow and will target an effluent water quality of 20 mg/L biological oxygen demand (BOD) and 10 mg/L total suspended solids (TSS). The solution can be expanded as the brewery grows.

Cambrian Innovation is installing more and more of its technology in craft breweries. We think that is cool, so we reached out to Matthew Silver, founder and CEO of Cambrian Innovation, to learn more.

Is there an increased importance being placed on water by craft breweries today?

Silver: By 2030, global water demand is expected to exceed global water supply by a full 40 percent. This renders the linear consumption of water, one of the brewing industry’s most valuable resources, unsustainable. Breweries that simply use and dispose of water expose themselves to risk, typically in the form of strict regulations and high fees for wastewater discharge, as well as water supply restrictions. This translates to high operating costs, which can leave a brewery unable to meet demand, putting them at a critical disadvantage in a rapidly growing, highly-competitive market.

Because of this, craft breweries are placing an increased importance on water, and many are turning toward water reuse to both reduce their water footprint and their exposure to water-related risk.

Can you break down the expenses/pay back of installing a system like this?

A conversation that we repeatedly have with breweries is around the true cost of water and wastewater management. At first glance, it seems nominal. But when breweries dig deeper and add up their water and wastewater costs, which include everything from the potable water and pH adjustment to trucking and BOD/TSS/TKN surcharges, they realize that they are spending millions of dollars on water and wastewater each year.

EcoVolt solutions both ensure compliance and eliminate many of those cost centers — i.e. high-strength discharge fees and trucking — and generate additional value for breweries by converting wastewater, once a cost stream, into renewable energy, a source of revenue. EcoVolt solutions are also more energy-efficient and produce less sludge than traditional wastewater treatment solutions. Because of these factors, our EcoVolt solutions have seen impressive payback periods and high rates of return. In many cases, they are even allowing customers to expand production and meet market demand.

Do you have any examples?

At Lagunitas Brewing Co. in Petaluma, Calif., for example, a self-powered EcoVolt solution eliminates more than 99.9 percent of BOD in the brewery’s spent process water and produces 3,120 kWh of renewable electricity, 126 therms of renewable heat and upwards of 80,000 gallons of recycled water every single day.

What size brewery do you think makes the most sense for an EcoVolt?

Our EcoVolt product suite makes onsite wastewater treatment and water reuse accessible to breweries of all sizes. Our largest EcoVolt solutions are currently serving breweries with annual productions upwards of 500,000 barrels, and our first EcoVolt MINI was recently delivered to a client that will begin with an annual production between 8,000 and 10,000 barrels.

We are currently seeing the most interest from breweries in areas where sewer charges are rapidly increasing, and in drought-stricken regions (such as California) and small cities where public treatment infrastructure is often overloaded. The breweries that we work with are typically facing strict regulations and high fees for wastewater discharge and are often unable to expand production without pre-treatment. Our EcoVolt solutions offer them a cost-effective, sustainable way to manage their wastewater.

Details on Russian River Brewing’s water treatment system and expansion https://t.co/Lm7reNDKiQ

Details on Russian River Brewing’s new water treatment system and expansion (should you buy one?) https://t.co/gsTT3CvrZ1 #beer #craftbeer