Nashville: Music City USA. Besides being the birthplace of country music, Nashville, Tenn., is known for great restaurants, an art scene and a vibrant night life. It’s no surprise Adler Lentz and Kurt Smith, business partners and owners of Smith & Lentz Brewing Co., decided to open their brewery in the vibrant and dynamic city. The brewery includes a taproom featuring 22 beers that is open to the public; additionally, Smith & Lentz has five distribution accounts in the Nashville area.

Smith’s love of craft beer developed early: While Smith was attending the University of Minnesota, Minn., from 2005-2009, he noticed that the area’s brewers not only were creating interesting and unique beers, they also were building and sustaining a sense of community around brewery culture. He had the opportunity to travel abroad during college, and thanks to a semester in Prague, he further developed his love for and interest in craft beers, which translated into a serious hobby. After college he moved to Austin, Texas, and while living there he brewed beer at home, learning the ins and outs of various brewing methods. Also in Austin, he worked as an environmental and risk consultant and found time to volunteer at local breweries.

Meanwhile, Lentz was working as an apprentice at a small brewpub in Milwaukee, learning the basics of commercial brewing. After his apprenticeship, he moved to San Diego and became a brewing equipment installer. For four years, Lentz built systems for a variety of breweries — from startup breweries to larger commercial ventures. One of the brewery systems Lentz installed happened to be in Austin.

“When I installed the Hops & Grain Craft Brewery system, I was offered a job as the head brewer, so I moved to Austin for the opportunity,” Lentz said. “Kurt Smith was friends with the owner of Hops & Grain, and that is where we met. The strange thing is we both realized we grew up in Wisconsin only 15 miles from each other.”

When Smith and Lentz met, it was clear that Lentz’s extensive craft brewing experience complemented Smith’s business acumen. The two craft beer aficionados started talking about building a brewery, taking only four months to create a solid business plan.

While working on the business plan, they considered where they wanted to locate the brewery, and Nashville was the city of choice. According to Lentz, Nashville has the perfect demographics for a brewery, and quality of life there is excellent.

“We were both looking for a change from Austin, and we were looking into a variety of different cities on the West Coast, such as Portland, Seattle and San Diego,” Lentz said. “My girlfriend is from Tennessee, so she suggested Nashville. We started looking at the demographics of the area, and they are identical to Austin and Portland, but a lot less breweries are located there, so we saw a great opportunity. We figured this was a great time to move there and open a brewery.”

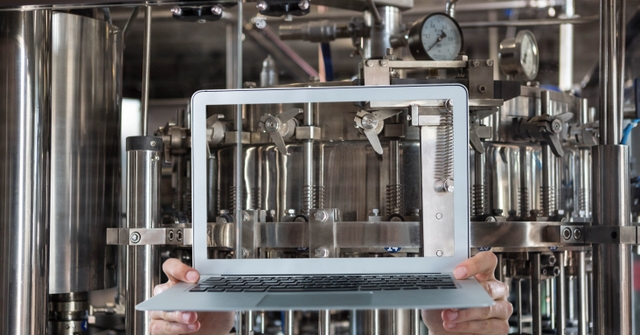

Once their business plan was completed, they moved from Austin to Nashville to start work on the brewery. They hit a temporary snag when a fire broke out in the brewery building, but it didn’t sidetrack them for too long: The entire project — from creating a business plan to opening the brewery to the public — took three years. Designing a glycol-cooling piping system for the brewing process, including research, product certification and installation, took only two months; the brewery then opened in the fall of 2015.

Research leads to decreased piping costs

Smith and Lentz researched a variety of materials, including copper, Schedule 80 PVC and ABS, to use for the glycol-cooling piping system. Eventually, they came across Ferguson Enterprises, a wholesale distributor of plumbing and mechanical supplies with 1,400 locations serving customers throughout the U.S., Puerto Rico, the Caribbean and Mexico.

“Adler Lentz came to Ferguson because of research he had done,” said Rick Hollis, product specialist at Ferguson. “He was installing brewing equipment and was looking into different materials.”

According to Lentz, he and his partner were considering copper, but its expense wasn’t feasible for their project. Hollis as well as Mike Nix and Pete Trautman, local Aquatherm reps with the manufacturers’ representative firm Mike Nix & Associates, Peachtree City, Ga., mentioned Aquatherm as an option for the brewery system.

“We had asked for prices on different materials, and they recommended Aquatherm,” Lentz said. “We then researched Aquatherm polypropylene-random [PP-R] piping systems, and this product offered everything we were looking for, plus more. The price of the Aquatherm pipe is great when compared with the cost of copper; plus, it has a good R-value [of 1 depending on pipe size and standard dimension ratio].

“Copper is more expensive, harder to work with, and it doesn’t have a good R-value,” he added. “Since PVC becomes really brittle when it gets cold, that was not a viable option for us either. We picked Aquatherm because of the price, R-1 insulating value per inch of material and the ease of installation.”

Lentz also was interested in Aquatherm because he had seen it two years earlier while in Florence, Ala., at the Singin’ River Brewery. The brewery had used Aquatherm for its glycol-cooling system as well.

Brewery owners tackle training and installation

“The brewery is a startup, so we are really lean. As a startup, you need to save money when you can, and labor is an area where we could save money,” Lentz said. “The quote for copper was about $20,000, and for a startup that is a big chunk of change, so when we got that quote we looked at other options. And that’s when it started to make sense that we should use Aquatherm and do the install ourselves. We saved about $12,000 by doing this.”

Before Smith and Lentz could start installing the Aquatherm piping in the brewery system, they needed to attend a training course at Ferguson’s Nashville location.

“To establish the warranty, Aquatherm requires that each installer complete a course on what they are installing,” Hollis said. “We have several courses the installer needs to pass. Aquatherm is installed using socket fusion, butt fusion, electrofusion and outlet fusion. We are with the installers every step of the way on this training.”

RT @BreweryWastewat: Smith & Lentz Brewing picks Aquatherm piping for glycol-cooling system https://t.co/9rGcw4yT0b via @craftbrewingbiz

Smith & Lentz Brewing picks Aquatherm piping for glycol-cooling system https://t.co/9rGcw4yT0b via @craftbrewingbiz

RT @CraftBrewingBiz: Chiller solution: Nashville brewers pick @Aquatherm piping for glycol-cooling system. https://t.co/ksKS4FNluf https://…

Shmadler Benz and Kurt chillin’…. https://t.co/Esg3vrm0Xy

RT @BountyBev: Check out this article about Nashville’s @SmithandLentz!

https://t.co/bBjPOHxCG4 https://t.co/zlxHmDbc2s

RT @BountyBev: Check out this article about Nashville’s @SmithandLentz!

https://t.co/bBjPOHxCG4 https://t.co/zlxHmDbc2s

Check out this article about Nashville’s @SmithandLentz!

https://t.co/bBjPOHxCG4 https://t.co/zlxHmDbc2s

RT @CraftBrewingBiz: Chiller solution: Nashville brewers pick Aquatherm piping for glycol-cooling. @SmithandLentz https://t.co/ksKS4G4WSP h…

David Snell liked this on Facebook.

Corey Lord liked this on Facebook.

#CraftBeer #CraftBrewing #Beer #BeerBiz Chiller solution: Nashville brewers pick Aquatherm piping for glycol-co… https://t.co/K7F9G7PFjd

Smith & Lentz Brewing picks Aquatherm piping for glycol-cooling system https://t.co/XncYmdXVx5 via @craftbrewingbiz