Cans have become a staple of the craft beer industry as brands garner their aesthetics around the sleek, clean and eye-popping look that aluminum renders. Breweries have lauded the superiority of can production versus amber glass as they cut UV exposure (i.e. there is none) and have environmentally friendly production because they are more compact for shipping. Simultaneously, the onset of mobile canning has become a cheaper, streamlined option for smaller scale facilities that can ill-afford the tens of thousands of dollars needed to purchase a canning line for themselves.

With the gargantuan growth of breweries over the past 10 years, canning has become a highly popular standard for production in the beer community. Gone are the days where an apocryphal metallic residual taste was prevalent and only the Big Three or lower-tier producers snatched up cans as a cheap boon to producing bottles.

However, this rising wave of popularity has a strong undertow, just as hop contracts and shortages have curtailed new breweries’ competitive advantage. Crown, a primary can supplier and printer has stopped receiving new customers. Huge disadvantages also include upping their minimum orders significantly and extending order times by two to six months, as they cannot afford to bankroll small breweries when production has already been snatched up by the bigger players. Ball, another main manufacturer, has not only overtaken Rexam, one of their primary competitors, but may result in further gridlock in can availability.

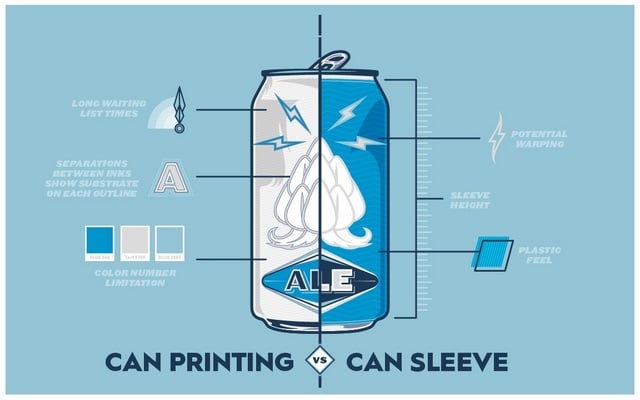

To curtail the panic, other options for production in the face of the can shortage are available. Primarily, can sleeves. Garnering attention over the past couple years, can sleeves are digitally printed and shrink-wrapped to the surface of the can. There are distinct advantages and disadvantages for sleeves, and below is a short summary from a packaging design perspective.

Printing on the can

Pros:

- No shrinking or warping of the artwork.

- Nostalgic customers appreciate the feel of the aluminum touch versus the plastic sheathing on can sleeves.

- If you like the look of aluminum, the design can be tweaked to allow the can substrate to show through for an interesting glossing effect.

Cons:

- Timeline: The most obvious obstacle when choosing whether to print your cans is your timeline. Even if you do scrape past your competition into the cut-off period with a can printing manufacturer, lead times can be as long as six months. So, when brewing quickly, or if you are an experimental brewery with many fast releases, this may not be the best option for you.

- Quantity: Ball and Crown’s minimums have increased to 12 pallets (100k cans) in order to fill a full truckload. With a can printer, you are often required to order very large quantities. Again, if you are looking to do faster, smaller runs, this may not be the option for you.

- Color: When printing to can, inks can become very transparent, showing the aluminum below, so making sure your designer understands the options, should you desire an opaque design, can be important. However, some inks are variable in opacity no matter what preset the designers anticipate. Ball, in particular, recommends running a white coating underneath the ink, as well as higher-end processes, to boost the opacity of the color palette. While more expensive, these options can get you just the look you are aiming for. NOTE: There is also a limit on how many Pantone colors you can use on a can (maximum six colors). If your artwork is rendered in detail with more colors, an alternate, simplified version of your artwork will have to be created just for cans.

Can sleeves

Can sleeves have come a long way in recent years. Gone are the days of a loose wrap or an obvious, cheap look compared to a printed can. Today’s sleeves come nearly to the lip to distinguish them from a printed can, and unless you are looking for the seam (usually on the back or side of the can), they are difficult to differentiate on the shelf.

Pros:

- Color: BRIGHT is not a problem. Nor is opacity, as a white layer under the artwork is a standard option. Because can sleeves also run digitally instead of picking specific Pantone inks, there are no color limitations per can, and there is a potential to run artwork that is not vectorized.

- Timing: As orders are processed within days, and turnaround is often weeks versus months, timing is no longer an issue.

- Cost: Smaller minimum quantities scale back baseline cost significantly, but sleeves are more expensive per can to produce.

Cons:

- Texture: Sheerly by the way it is produced, there is a plastic, glossy texture to the sleeve. This may turn off some customers, and is more apparent as the can bends while the consumer is drinking it.

- Shrinking: To reiterate, your designer needs to understand the fundamentals of how can sleeves are produced and printed, as the shrinking that occurs can cause warped artwork and you can lose important information during this process. There is a specific area near the joint of the sleeve when shrink-wrapped that folds and condenses the area significantly.

Ultimately, as with any shortage, breweries and manufacturers will be pushed to explore the boundaries of cans and innovative packaging. Until then, we look forward to drinking the results!

Written by the team at Watermark Design, a nationally-recognized branding and design studio. Watermark has been marrying design + craft beer since 2010, creating award-winning brands and package design for their clients’ breweries. Their love of beer + storytelling through design collide into some amazing collaborations. They are passionate about their craft, if you are passionate about yours, give them a call.

KingofJordan69 says

You forgot a massive con: More single use plastic ending up in the environment, especially the ocean.

Jason Roberson says

Contact Jason C. Roberson for Expert Craft Beer Can Design:

http://consumerproductbranding.com/

Jesse Miller liked this on Facebook.

Benjamin Fisco liked this on Facebook.

Hunter Smith liked this on Facebook.

Jonathan Cahoon liked this on Facebook.

RT @CraftBrewingBiz: The pros and cons of printing on cans vs using can sleeves. We ask the experts @watermarkdesign https://t.co/fPaxSSseqy

Fred Searles liked this on Facebook.

Ryan McCabe liked this on Facebook.

Darcey Ohlin Lacy liked this on Facebook.

Jeff Platt liked this on Facebook.

RT @CraftBrewingBiz: The pros and cons of printing on cans vs using can sleeves. We ask the experts @watermarkdesign https://t.co/fPaxSSseqy

Beth Demmon Ivey liked this on Facebook.

Isaac Arthur liked this on Facebook.

RT @CraftBrewingBiz: The pros and cons of printing on cans vs using can sleeves. We ask the experts @watermarkdesign https://t.co/fPaxSSseqy

@craftbrewingbiz @watermarkdesign We’re starting to see printers who can produce can sleeves with varnishes & other cool textures as well.

RT @CraftBrewingBiz: The pros and cons of printing on cans vs using can sleeves. We ask the experts @watermarkdesign https://t.co/fPaxSSseqy