What makes a quality craft beer can? Instantly you might say graphics because those shiny colors are often what cause shelf and cooler browsers to make a purchasing decision. But no, a quality can is determined well before that moment by its seam. To put it mildly, a bad seam will ruin your day.

For those just jumping into cans, monitoring seams for quality is an arduous but highly important process.

“In the past we had an old vision system: manually cut a can open and then manually write down what dimensions we found and try to track things that way,” said Jim Weatherwax, Plant Manager, Oskar Blues.

Luckily, there are solutions on the market now that can handle this work in a swifter and way more efficient manner — allowing for instant analysis and image storage. Weatherwax continues:

“Now, we do seam checks every four hours while we’re running. We start up after the seamer gets warmed up a little bit, we pull four cans off, and run em through and make sure everything is in spec.”

“We used to manually check our seams with the micrometer and tear down the seams by hand with basically a pair of pliers and tin snips — until we got the new seam saw and countersink gauge, and video seam imager. So its been a lifesaver for sure,” said Larry Schriver, packaging manager for Cigar City.

As is often the case, if you are able to offload menial/annoying tasks to a robot, you should consider it, especially when quality control is at stake.

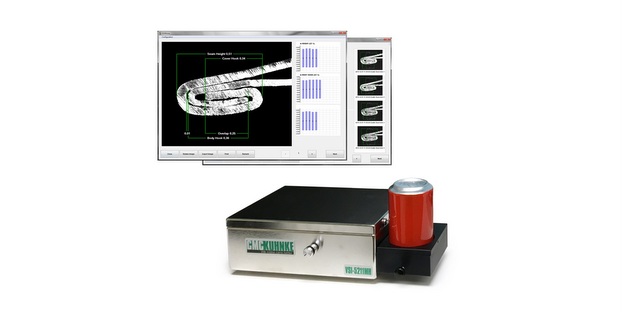

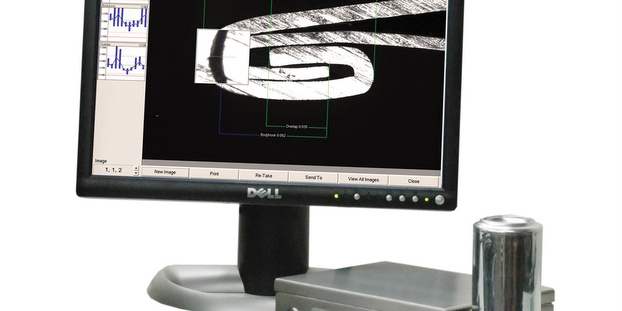

“It kinda got to be to the point that we were growing so quickly, especially in can package, that we needed a little bit more help,” said Brett Zahrte, packaging manager for Epic Brewing, which eventually upgraded to CMC-KUNKE’s SEAMview. “My personal favorite feature, because I’m a data geek, is being able to control how many images I’m storing, whether it is a week’s worth of canning and seam images, or a month’s worth, with CMC-KUHNKE’s SEAMview 5 data storage, I can choose. And that’s made a huge difference in our process control. The bottom line is, it would cost me a lot more to recall or hold and destroy 1,100, 1,200, 2,500 cases of beer that were questionable without this sort of equipment to help me to decide,”

We highlighted a couple of these seam inspectors prior to the CBC, and hopefully on your trips around the show floor you were able to check them out. The perspectives of the brewers above were sent our way view CMC-KUHNKE along with this fancy video compilation of testimonials and the technology in action. Give it a look.

RT @OneVisionCorp: Brewery packaging managers explain the importance of can seam inspection https://t.co/3aAUTpplVU via @craftbrewingbiz

OneVision Corporation liked this on Facebook.

Brewery packaging managers explain the importance of can seam inspection https://t.co/3aAUTpplVU via @craftbrewingbiz

RT @CraftBrewingBiz: Brewery packaging managers explain the importance of can seam inspection. https://t.co/PgpJWAL4l8 via @CMCKUHNKE

Brewery packaging managers explain the importance of can seam inspection https://t.co/jLrzprIZaw

Henrique De Luca liked this on Facebook.

Wade Ferguson liked this on Facebook.