Karbach Brewing Co. was founded in Houston in 2011. Since then, the brewery has been writing a remarkable success story. After two years, the brewery produced 20,000 hectoliters of beer; for the third year an annual output volume of 40,000 hectoliters was forecasted. At about 47,000 hectoliters the brewhouse reached, however, the limits of its capacity. Consequentially, the brewery decided to expand the capacity by building a new brewhouse and by extending the cellar. Since the end of 2014, both investments have proved themselves in daily practice.

“First of all, we wanted to have more capacity,” summarized Eric Warner, co-founder and brewmaster of Karbach Brewing. “With our 35-hectoliters brewhouse we have been producing beer 24 hours a day, seven days a week. At the same time, we were looking for a brewhouse with higher yields.”

The factor “yield” plays an important role for craft brewers due to the high hop dosing rate.

Warner explained: “In the USA, we are producing very strong beers with cone hops or pellets. Thus, the trub content is correspondingly high. Most whirlpools have difficulties to separate this trub from the wort. With extremely hopped beers, we sometimes had wort losses in the double-digit percentage range.”

From Denver to Houston via Weihenstephan

Eric Warner is a true veteran of the craft beer movement. In the 1980s, Warner, born in Denver decided to jump across the pond to Freising in Bavaria. There, he studied brewing technology at the Technical University of Munich/Weihenstephan and graduated as diploma brewmaster. Afterwards, he held positions in renowned breweries in Germany and the United States. The experience gained in Germany was later reflected in his books “German Wheat Beer” and “Kölsch” — both are now classics of the literature for craft brewers.

Eric Warner is also known for his work at the brewery Flying Dog Brewery in his hometown Denver. There, he brewed successful beer specialties like Snake Dog IPA, Double Dog Double Pale Ale, Gonzo Imperial Porter and Dogtoberfest Märzen, from which the output volume of the brewery quintupled during that time. When Flying Dog moved its production facility to Maryland, Warner decided that it was time to meet new challenges.

RELATED: Ziemann debuted new brewing equipment technology at BrauBeviale 2014

At Karbach, Warner started with three beer types. First, this was Hopadillo IPA with an original gravity of 15.5° Plato and 65 bitter units. Today, Hopadillo is the main brand with a share of approximately 35 percent of the total output. Second, the Weisse Versa Wheat, which is fermented with a German wheat beer yeast and flavored with coriander and citrus peels, like a Belgian Wit. Third, the Sympathy for the Lager — a hopped, German-inspired bottom-fermented lager. Meanwhile, the standard portfolio has grown to five brands. The last one, a Kölsch-type beer, was introduced last year. In addition, two strong beers called “bombers” are offered all the year round. Karbach’s portfolio is completed by seasonal beer specialties, like the Oktoberfestbier and an experimental range of beers, aged in Bourbon or wine barrels. With this portfolio, Karbach Brewing has become a fast growing brewery. Warner explained: “We benefit from the major trend that the Americans do not consume a larger quantity, but a higher quality. This applies to wine, coffee as well as to beer. In this respect, a sustainable change of the consumer behavior can be noticed.”

An interesting detail: Karbach is one of those craft breweries, which mainly uses the 0.33-liter can in a six-pack as packaging instead of the ubiquitous bottle. For Warner, there are many arguments in favor of the beer can. The can is easy to transport, protects the beer against sun rays and does not need a label. Last but not least, Warner is of the opinion that the beer can matches perfectly with the Texan lifestyle: “Texans like to be outdoors.”

Brewhouse equipped with the latest brewing technology

Karbach did not hesitate to equip its new brewhouse with the latest state-of-the-art technology and did not choose equipment and technologies, which have already been on the market for quite some time. The brewery decided in favor of the latest innovations. Warner mentions good reasons for choosing this innovative equipment: “The main craft beer type in the USA certainly is the IPA. But the growing breweries also offer Belgian- or German-style beers. Modern brewhouses provide you with the required flexibility to carry out the optimal brewing processes for all beer types. You are able to produce a classic English Ale with an isothermal infusion process just as well as carry out boiling processes with part of the mash or keep complex rests. All this is possible with highest possible constancy and yield values.”

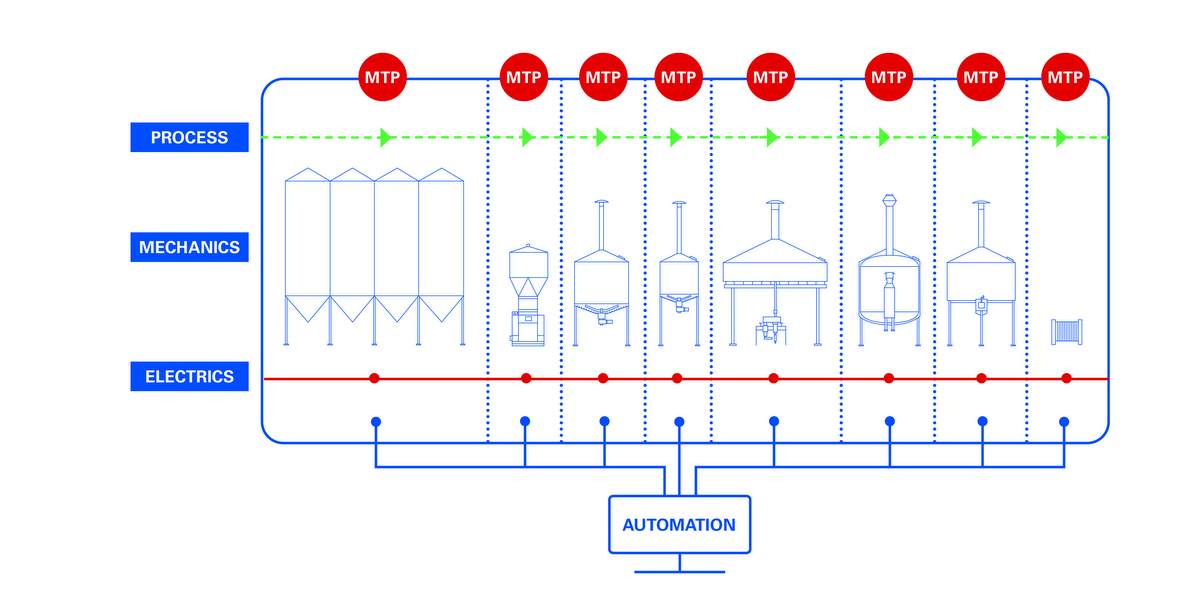

The brewhouse is designed for a maximum of 12 brews per day, with a cast-out wort volume of 140 hectoliters. With the new tank farm consisting of six CCTs, each with a capacity of 700 hl, the annual production capacity of the brewery is increased to almost 120,000 hectoliters. By retrofitting additional tanks, the capacity of the brewery can be expanded to an annual output of up to 400,000 hectoliters. In addition to the brewhouse and the tanks, the project also included the automation of the plant and the integration of the malt handling.

Paul Feaver liked this on Facebook.

#CraftBeer #CraftBrewing #Beer #BeerBiz The story of Karbach Brewing expanding its capacity with Ziemann brewho… https://t.co/KH2mTuS2X2

The story of@@karbachbrewing expanding its capacity with Ziemann brewhouse https://t.co/5Z57rx0QSd via @craftbrewingbiz