The science of commercial beer goes beyond the chemistry of brewing. The process of packaging is an equally impressive engineering feat, requiring bottling, canning, kegging, labeling, sorting, accumulating, boxing, palletizing, shipping and so much more in between. Visit a packaging and distribution center at a brewery like New Belgium Brewing Co. and the automation of the packaging process can look a little like an ultra-complex Rube Goldberg Machine. When it comes to automating that packaging process, few companies do it as well as Intelligrated, a material handling automation and software engineering company based in Mason, Ohio. Below are three impressive products that the company makes.

Robotic variety pack solution

Intelligrated’s Alvey robotic variety pack solutions allow brewers to accommodate consumer preferences for packaged assortments with an effective, single-source automated material handling system. Equipped with patented multi-row, configurable tooling that saves floor space by eliminating the need for tool-changing devices, the solution automates tasks including sequencing, palletizing, depalletizing, un-casing and SKU-mixing. Scalable variety pack solutions are designed to meet brewers’ unique requirements, with clamp, vacuum or a combination of end-of-arm tooling options to handle virtually any can, bottle or case. Intelligrated’s automated variety pack solutions decrease manual handling requirements to reduce labor costs, improve order fulfillment speed and deliver increased throughput and accuracy.

Robotic palletizing

Intelligrated’s conventional and robotic palletizing solutions offer the versatility to handle a variety of layer pattern, product packaging and container demands. An ideal solution to streamline distribution for growing craft operations and established brewers alike, conventional automated and robotic palletizing solutions from Intelligrated handle multiple SKUs and product changeovers while improving palletizing speed and cost efficiency. Designed to handle a broad range of case sizes, orientation requirements and container demands, Intelligrated’s Alvey palletizing solutions provide optimum flexibility and scalability on the line. Robotic palletizers feature customizable end-of-arm tooling and integrated software and machine controls to increase throughput capacity and enable convenient product reconfiguration for improved ergonomics and reduced labor costs in a variety of applications.

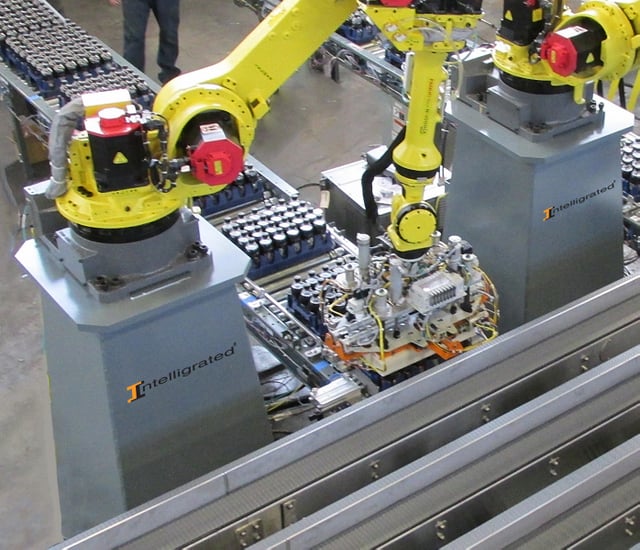

Robotic bulk depalletizing

Alvey robotic depalletizing solutions from Intelligrated replace the labor-intensive task of manually unloading product and ingredients from pallets with the speed, accuracy and repeatability of automation. Using robotic arms from multiple manufacturers, such as Motoman, Kuka and Fanuc, Intelligrated integrates standard and custom end-of-arm tooling designed and built in-house to precisely move and place a wide range of product shapes and sizes. Optional vision systems enable more accurate operation, and compact, flexible layout configurations occupy minimal floor space and enable easy implementation in bulk receiving applications. Intelligrated offers a wide selection of peripheral equipment to satisfy product-handling needs and the consistent, predictable throughput of robotic bulk depalletizing solutions enables improved utilization of downstream equipment.

Serge Lubomudrov liked this on Facebook.

Jaime Peña Gonzalez liked this on Facebook.

@CraftBrewingBiz @Intelligrated But aren’t those soda bottles? But I’m sure they can tweek the machine to work with cans or bottled beer.