Fast growing Two Roads Brewery, located in Stratford, Conn., needed a solution to problems involving outdated tank-based glue equipment used to seal cardboard packaging. The equipment was causing downtime and jeopardizing its production goals. The brewery eventually opted for a technology upgrade, the InvisiPac Tank-Free Hot Melt System, which has reduced its downtime, freed up operations personnel for more productive tasks and improved the efficiency of its packaging process.

Brewery seeks solution for sticky situation

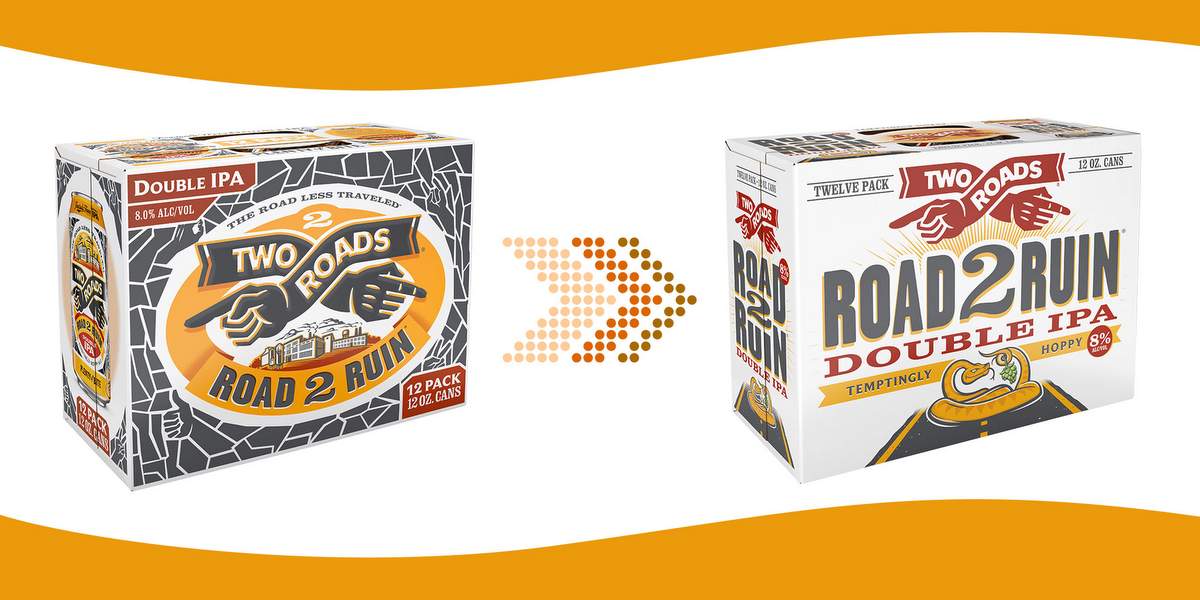

Two Roads Brewery is one of the fastest growing microbreweries in the Northeast. Since beginning operations in 2012, Two Roads has increased production from 30,000 to 120,000 bbls per year. The proud member of the emerging craft brewing fraternity brews its signature beers in a beautifully restored 100-year-old factory in Stratford, Conn.

After cleaning, scraping and painting the old brick, wood and steel of the former metal forming machinery company, the brewery added the latest state-of-the-art brewing and fermenting equipment. Soon after they began operations, Two Roads found its production line growth hampered by frequent plugging of the tank-based hot melt delivery equipment that it was using to glue boxes together. On the factory’s second floor, cardboard boxes are unfolded by the case erector; the bottom of each box is glued and sent down to the bottling facility. After the bottles are filled, they are sent to another machine to be loaded into cases, which are then sealed on top using another hot melt unit.

As Doug Concialdi, Two Roads’ packaging manager, explains, there were issues with the glue system, which was used equipment Two Roads had inherited. The system took nearly an hour to heat up, putting pressure on the production schedule. In addition, they were experiencing char, which is by far the biggest problem in any hot melt application system. [1]

Char occurs when the properties of the adhesive are altered through thermal and oxidative degradation. Char results in hard clumps that have lost their thermoplastic nature and will not flow. This charring was a key cause of the nozzle plugging Two Roads experienced.

The system was also subject to human error – operators frequently had to ask, “Did someone turn on (or off) the glue machine?” The long startup time resulted in a loss of valuable production time if the machine hadn’t been turned on. To make matters worse, Two Roads was told by the vendor that the system was being phased out and they would not be able to buy replacement parts.

“I asked our glue supplier for a recommendation for a new unit, since there is a marriage between the materials and machinery,” Concialdi said.

Chester Duff, adhesive division manager of Astro Chemicals Inc., helped Two Roads update its equipment with more advanced technology. Astro had previously helped Two Roads with a labeler and packaging equipment and supplies them with glue and other chemicals used in beer manufacturing, as well as cleaning agents.

Duff had already been investigating a system from Graco, the InvisiPac Tank-Free Hot Melt System, which showed promise in improving productivity and ease of operation in hot melt applications. The system was designed to reduce char and completely eliminate the frequent plugging of nozzles in glue systems. The system was also designed to stabilize glue consumption rates and reduce both adhesive waste and waste in the form of boxes that need to be repacked or resealed because of an inadequate seal.

“Glue nozzle plugging is an industry-wide issue that had previously been considered a given,” Duff says. “Companies like Two Roads have just had to keep plenty of nozzles on hand and stop the line whenever they needed changing.” Duff says this particular equipment had to be changed three times a week, and since it was a 4-nozzle applicator, it had a major impact on downtime.

Having to stop the line for packaging issues can result in a significant time loss, which translates to a huge amount of lost revenue. Breweries have a production schedule to keep that may involve, perhaps, three different beers that must be canned or bottled on a particular day. Once the beer is in the filler, it cannot be stopped or it backs up the whole system.

The cost of downtime varies, but Duff estimates it can range from about $2,000 per hour to tens of thousands per hour, depending on the size of plant. If a nozzle is plugged once a week and takes 15 minutes to fix, that is equivalent to an hour a month or 12 hours a year. At a cost of say $3,000 an hour, that would be $36,000 per year. If it happens two to three times a week, costs really add up, especially if the plant runs 24/7.

New technology introduced

When he first saw the new InvisiPac system, Duff was not an instant convert, wanting conclusive proof it was going to work before recommending the system to customers. He became a believer after installing the technology at a nearby glass beer bottle manufacturing plant with extremely challenging conditions. The company had such severe plugging that it used and discarded two nozzles each day. From the instant the InvisiPac went online, the new equipment performed flawlessly, virtually eliminating downtime due to glue nozzle plugging. Duff reasoned if the system could perform so well in a harsh environment polluted with airborne contaminants, it would be a good fit for the sparkling shiny new facility that was Two Roads.

The InvisiPac technology incorporates an integrated vacuum feed, Tank-Free melter, heated hoses, an innovative applicator and process control technology that provides easy, remote system analytics. With the Tank-Free system, adhesive is used on a first-in, first-out basis, reducing adhesive residence time, so there is essentially no char. Better adhesive quality leads to improved bead weight repeatability. Less char, combined with the no plug applicators, means adhesive beads can be right-sized, resulting in less adhesive consumption and improved quality assurance.

“This is technology that I believe will revolutionize the industry, which has been depending on what I call the ‘crock pot’ system for 70 years,” Duff says. The analogy refers to the fact that most glue systems sit with glue in the unit like pot roast in a crock pot – slowly cooking for hours and leaving a residue of grease around the pot; with the hot melt system, the glue cooking for many hours causes charring that leads to nozzle plugging.

Testing the new technology

Astro Chemicals, Inc. arranged to bring in the technology at no charge to demonstrate its effectiveness. If the system did not perform as promised, Astro agreed in advance to remove it and replace it with Two Roads’ old system. The arrangement reduced the risk for Two Roads, ensuring positive results before it made the investment in new equipment.

They installed one InvisiPac Hot Melt System in December 2013 and added another unit in August 2014. Since they pushed the button the first time two years ago, Two Roads has never even had to change the filter or replace a plugged nozzle. Only after switching to the new equipment did the brewery realize how much smoother its process went without having to live with the constant issue of plugged nozzles.

(Click “Next” to continue reading the story and to see a fancy chart.)

CRAFT GLUE: @CraftBrewingBiz: Boxing & Packing Case Study w @2RoadsBrewing #ctbeer #craftbeer http://t.co/IGlcwwIoNf http://t.co/zc8KQACrSZ

Hot melt! A Two Roads Brewery production demand case study http://t.co/4dsUXDkY5j @craftbrewingbiz @2RoadsBrewing http://t.co/UfcRblDkHl

As featured on @CraftBrewingBiz: “Fast Growing Brewery Uses Graco’s Hot Melt Technology to Meet Production Demands.” http://t.co/32oeEkTkty

Hot melt! A Two Roads Brewery production demand case study http://t.co/rTQHzgXlU2

Jared Read liked this on Facebook.

Hot melt! A Two Roads Brewery production demand case study http://t.co/WlttJqipxH via @craftbrewingbiz