If there were a beer dartboard for the state of Michigan, Arbor Brewing Co. would be sitting toward the center of it. Consider: Microbreweries are growing at an amazing rate. According to our very own Craft Brewing Business, craft beer production was up 18 percent annually in mid-2014, and Michigan, which is known as “The Great Beer State,” is home to 150 craft breweries.

Holding a cup that virtually runneth over with craft beer, Michiganders have their choice of some of the finest craft beers in the world, and they have continually supported Arbor Brewing Co. (ABC). The kegs were tapped at the ABC Pub and Eatery in downtown Ann Arbor, Mich., in July 1995, and the company has regularly expanded. Out-of-staters frequently take home a couple cases or growlers at a time, and the brewery recently expanded distribution to northern Ohio and Connecticut.

A commitment to handcrafted beer, exceptional hospitality, local sourcing, community involvement and environmental stewardship has been the foundation for ABC’s growth and success. The brewery was founded by husband and wife team Matt and Rene Greff, who share a passion for beer and adventure. By their late 20s, the Greffs had become disenchanted with their corporate gigs and soon after brewpubs were legalized in Michigan, they set about opening their own brewery. They raised their startup capital through a network of friends, family and co-workers and became the first brewpub to open in Ann Arbor and the fifth to open in Michigan’s fledgling microbrewery movement.

Having survived some rocky early years, by 2001 ABC maxed out capacity on its 7-barrel (bbl) system and expanded to an adjacent building with the addition of a small banquet space, an additional 30 bbls of fermentation and serving-tank capacity.

Growing and greening

The Greffs wanted to create another brewery to produce and bottle their award-winning beers and as long-time Ypsilanti residents, wanted to help spearhead the economic renaissance in their hometown. Thus, they selected an abandoned warehouse tucked into a residential neighborhood a few blocks off the beaten path.

The Microbrewery Brew Pub and Beergarden quickly became a regional destination and a favorite local hangout, and by 2010 the brewery was bursting at the seams. So the Greffs embarked on an ambitious $1 million expansion and green brewery renovation project. In addition to the green renovations, the project doubled the amount of car parking, tripled the amount of bike parking, and added 2,200 square feet — including new warehouse and office space, while doubling the brewing capacity and increasing bottling speed five-fold by 2014.

According to Dan Peron, the director of brewery operations at Arbor Brewing Co. Microbrewery, formerly known as Corner Brewing Ypsilanti, ownership took a very green approach to the Ypsilanti expansion.

“Doing a brewery in an environmentally friendly way is kind of something you have to be naturally inclined to want to do in terms of your product and your philosophy. You can follow suit and do what we’ve been doing for decades and centuries, or you can dig a little deeper and put forth a little bit more effort and investment to make more of an impact,” Peron said.

From the Greffs on down, the company sought to not only use the best, most natural ingredients in its brews, but also use the most environmentally friendly processing pipe, solar arrays, thermal collection system and so forth.

“It really kind of adds a little bit more to what we are all about, and I think that each and every employee here in turn carries that as a badge, that they’re proud of where they work and also believe in those same ideals,” Peron continued.

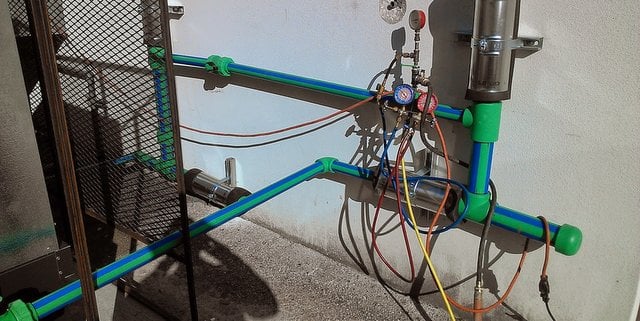

Mike O’Brien is known around the brewery as “Brew-Gyver.” He has earned this title (an apt reference to the 1980s show MacGyver) from his ability to creatively keep ABC’s mechanical systems running smoothly. O’Brien explained that the longevity and sustainability of the facility’s piping systems was a priority. A brewery depends heavily on all sorts of piping beyond the obvious brew process piping and thanks to a local contractor, ABC discovered a German-manufactured polypropylene piping system ideal for several of the expansion’s applications.

Peron had worked with heat-fused plastic pipe systems in the irrigation industry and was familiar with the dependability of the fusion joining method. Upon further research online, the design team felt Aquatherm was the best choice for the brewery’s geothermal piping to condition the beer cave, as well as for some domestic water supply.

Michigan Breweries liked this on Facebook.