The fight for quality beer marches on. We reached out to a couple established craft breweries to hear about the composition of their quality assurance (QA) programs. Maybe there is a task or two you’ve been overlooking in your own operation.

Real Ale Brewing

Located in Texas, Real Ale Brewing is in its 19th year and produces around 65,000 to 70,000 barrels (bbls) per year, with all of its distribution contained inside the state of Texas. Thomas Erwin is the brewery’s lab specialist. Here is everything he identified under Real Ale’s QA program:

Hourly

- Seam checks on all can line runs

- Package headspace sire readings and crown crimp checks

- Inspection of crowns, labels, fill levels, glue pattern on boxes, date stamps on bottles, cans and boxes.

All batches

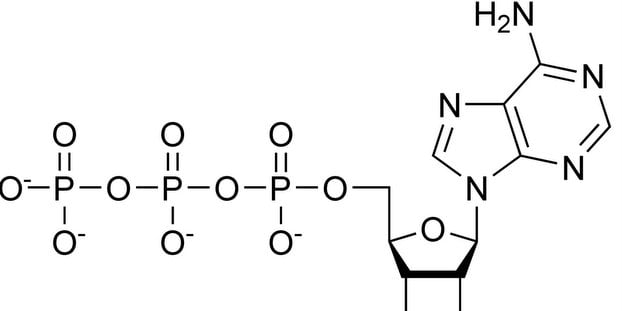

- Brewers take pH and gravity readings on all batches

- Yeast counts and viability on every pitch

- IBU and SRM.

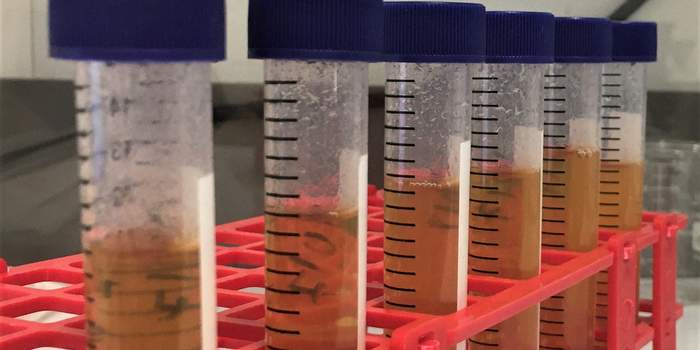

- Full micro testing on every batch about 24 hours after the pitch and 1 week after the pitch.

- Brewing and cellar staff taste and inspect all package runs.

Weekly

- Full micro on brite tanks

- Full micro on all packaging runs and switches from brand to brand

Two times a week

- Forced wort testing checks the hot side CIP and heat exchanger integrity.

- ATP testing on can/bottling lines.

Bi-weekly

- Sensory panels tasting cold aged product at month intervals.

When Erwin says they perform a “full micro” on all batches, he is looking for anaerobic and aerobic plate counts, sacchromyces wild yeast plate counts and non-sacchromyces wild yeast plate counts. These tests can really save the day.

“We once had the booster heater for the filler go out and therefore the pasteurization of the filler was not at the correct temperature,” Erwin said. “We had already run 600 cases or more by the time we noticed it. The micro revealed a small level of anaerobic contamination so the entire run pre re-pasteurization was held and dumped.”

What should you be doing?

Erwin believes a small brewery should be able to handle everything in that list. The only processes that carry a real price tag are the IBU, SRM and ATP equipment. If he had to boil that list down to the musts:

Package headspace air is really important. Erwin said the constant and intensive monitoring of headspace air and total package oxygen has been maybe their biggest lifesaver. Real Ale checks it with a headspace air tester, which run around $2,000 and are inexpensive to maintain and use.

Micro sampling on fermenters, brite tanks and packaged product are also fairly cheap to perform, but good aseptic technique and sterile containers are a must.

Sensory panels will require some work up front in terms of training, but after that they cost very little, and they can provide some extremely important data. Breweries cannot just go by taste off the line as the taste could possibly fall apart once the beer is out in the world.

“Quality assurance is a brewery’s best ‘insurance policy,’” Erwin said. “A lot of QA tasks are very cheap and just require a clean space and someone with some time. Of course, a small brewery shouldn’t run out and jump into gas chromatography and total package analyzers, but they should spend enough so that they can really trust the data they get from a QA program.”

Left Hand Brewing

Most recently ranked No. 38 in the Brewers Association Top 50 craft breweries based on volume, Longmont, Colo.-based Left Hand Brewing breaks its quality department into four subsections: Biological; Chemical/analytical; Sensory; and Field quality.

“As new employees are trained by seasoned staff who have developed unique approaches to their duties, this game of telephone allows for discrepancies to evolve,” she said. “Observing and validating each employee is incredibly important but must be followed with explaining why a task should be performed a certain way. Providing an explanation makes every individual understand the potential influences of deviating from a procedure and the benefits of performing a task as similarly to another as possible.”The biological technician performs wort stability checks, plates samples from the first and last 48 hours of fermentation, plates yeast samples, performs gram staining, monitors yeast generations, trains brewing staff on cell counting, tests bottles from every packaging run and the jetter/rinser water using membrane filtration, and collects aseptic samples including estimated attenuation.

The chemical/analytical technician handles grist analysis, water-quality testing, ABV, IBU, TPO, O2, CO2, N2, color, stability, kettle fining optimization and instrument calibrations. Left Hand also performs daily tank testing throughout fermentation to determine what actions need to be taken. Crowns, labels and bottles are all tested to ensure they meet specification. COA’s on all incoming raw materials are reviewed for compliance.

Sensory analysis is practiced at every step: At hop selection; throughout fermentation; During maturation for certain styles; Prior to packaging; Immediately after packaging; and Throughout the shelf life of the beer. “Before my morning coffee, I taste at least two beers,” reports Kate Devine, QA, lab manager for Left Hand Brewing.

Field quality covers taste testing beers on tap, troubleshooting pouring issues and training representatives on proper line maintenance and good practices.

Devine gives a good reminder that a brewery’s QA concerns don’t stop once the beer is sent out to bars and restaurants.

“Our chief of quality will always sample our beers when at a restaurant, tap house, etc. While waiting for a flight, he ordered a Milk Stout Nitro at an airport bar,” Devine said. “The bartender approached him with a bottle and glass saying, ‘Now this may scare you, but I’m going to do it anyway.’ He uncapped the beer and swiftly turned it vertically above the glass shaking vigorously. Pouring our nitro beer hard is crucial to obtaining an accurate mouth feel. This was an excellent example of the experience we want our customers to have when ordering our beers.”

The biggest problem Devine experiences day to day is maintaining consistency.

“As new employees are trained by seasoned staff who have developed unique approaches to their duties, this game of telephone allows for discrepancies to evolve,” she said. “Observing and validating each employee is incredibly important but must be followed with explaining why a task should be performed a certain way. Providing an explanation makes every individual understand the potential influences of deviating from a procedure and the benefits of performing a task as similarly to another as possible.”

What should you be doing?

“All of it. Every employee at Left Hand’s main job is to assure the quality of our product. We now have a staff of 100 quality team members that impact what reaches our customers’ glasses. No matter the size of your brewery or the finances available, hire people who care about quality and are passionate about beer,” Devine said.

Obviously smaller breweries, no matter their best intentions, will not be able to do everything a large craft brewery’s team of 100 is able to do. For smaller breweries, Devine says sensory analysis, ATP swabbing, testing specific gravity throughout fermentation, and cell counting all have low up-front costs, do not have large time allotments, and do not require many consumables. On a budget, breweries still need to make sure they have proper sanitation, quality ingredients, accurate yeast pitching, sensory analysis, good manufacturing practices (GMPs) and staff members that are invested in what they do.

Devine recommends, more than anything, picking up the “A Guideline to Growing Your Quality Laboratory” pamphlet from the American Society of Brewing Chemists (ASBC) that addresses testing and equipment a brewery should have based on production size.

“The formation of organizations that promote communicating brewing knowledge is extremely important,” she says. “Webinars, forums, text books, scientific methods, and research studies are being compiled and shared. We are no longer solely learning from our own experiences but also from those of others. New or small breweries have access to the same information as the big guys.”

We assume she also meant to include “fun trade websites.” Click that link to browse through some other QA features we’ve had through the years, and definitely stay tuned for others that will pop up throughout the year. If you have a specific process or product you’d like us to get more info on, just let us know.

Setting up a craft brewery quality assurance program http://t.co/Pcx44GVoIa #brewing #craftbeer

RT @RealAleHouston: BECAUSE QA MATTERS, BEER PEOPLE: Setting up a craft brewery quality assurance program http://t.co/2Ul5Gv9SUc

Need to focus on craft beer quality? Here’s a way to start >> Setting up a craft brewery QA program http://t.co/zuI8dvSdMu @CraftBrewingBiz

BECAUSE QA MATTERS, BEER PEOPLE: Setting up a craft brewery quality assurance program http://t.co/2Ul5Gv9SUc

Setting up a craft brewery quality assurance program http://t.co/G93gsc0Kio via @craftbrewingbiz

Setting up a craft brewery quality assurance program:

http://t.co/696F9BCzmf

Luke Gordon says

Great article!

Setting up a craft brewery quality assurance program http://t.co/cPLWYCDewH via @craftbrewingbiz

Setting up a craft brewery quality assurance program http://t.co/A5YvV4BUhW #MuchoMacho #Michelada… http://t.co/bhUKUD4Por

Setting up a craft brewery quality assurance program http://t.co/1aqM75orSj #MuchoMacho #Michelada… http://t.co/e3Dd7cLAaY

RT @HughesBrews: Setting up a craft brewery quality assurance program: http://t.co/bIbHaDFMWt via @craftbrewingbiz

Our Quality Assurance lab tech Thomas talked to Craft Brewing Business about how we ensure our beer’s quality: http://t.co/APCrH9XDy5

RT @HughesBrews: Setting up a craft brewery quality assurance program: http://t.co/bIbHaDFMWt via @craftbrewingbiz

Chip Gaul says

great article, we’re getting our lab at RJ Rockers underway, and all the information I can get is helpful!

Setting up a craft brewery quality assurance program: http://t.co/bIbHaDFMWt via @craftbrewingbiz