Depending on where you are, wastewater emanating from your brewery can be a non-issue or it can be a major deal-killer type of problem. That’s quite the variation, and it’s true. You will sleep better and have fewer headaches if you are lucky enough to fall in the non-issue end of the spectrum, but not everyone is so blessed. This article will provide a little of bit of insight in to the wonderful world of brewery wastewater and what to do with it.

This article is written primarily for small production brewers who discharge to a local wastewater treatment plant, but all brewers will find helpful nuggets of information in here as well. There are three main issues to address with regards to the wastewater — pH, concentration of BOD and TSS. Biochemical oxygen demand (BOD) is a measure of the nutrient value of wastewater. Total suspended solids (TSS) is a measure of suspended solids in wastewater. Brewery wastewater is higher in sugar and alcohol compared to normal domestic wastewater which most treatment plants were designed to treat.

The pH swings from high to low as well. Some less common restrictions may be for temperature, ammonia or an instantaneous or daily flow limit. Some towns apply reasonable surcharges for wastewater, other towns are highly excessive. Fats, oils and greases (FOG) is a big deal with municipalities these days, but brewery wastewater has almost no FOG. Each one of these characteristics can be major issues, and to make matters even more fun these vary state to state as well as town to town.

My main piece of advice to all prospective brewers is to do at least a little bit of due diligence before buying your property. Talk to the public works director and ask about available sewer capacity, surcharge rates and potential discharge limits. Make the property purchase contingent on acceptable rates and restrictions if the real estate people are rushing you. Some towns will be very strict, others may have had a mill shut down and has plenty of capacity at the treatment plant. If you don’t like what you hear, start digging for more information or look at the next town over.

As mentioned, the pH of brewery wastewater goes all over the place. On brew and packaging days, the pH will tend to be low, around 5. On CIP days, the pH will be high, around 12 or so. As wastewater sits, wild yeast and bacteria will ferment in the water and generate acids, lowering the pH as it ages. The EPA pH discharge limits are between 5 and 11 and most towns are stricter than that. You want the widest range here as possible, otherwise you’ll have to add chemicals to your wastewater just to adjust the pH – figuratively putting money down the drain.

The cheapest chemicals to use for pH adjustment are 50 percent NaOH and 96 percent H2SO4. These are commodity chemicals and can be relatively inexpensive, but of course they’re very concentrated and dangerous to work with. Give these products the respect they deserve — lest you be maimed.

Low pH wastewater is corrosive, high pH tends to lead to deposits. Another corrosion factor to be aware of is hydrogen sulfide gas, H2S. By itself it’s not so bad (its causes the rotten egg smell), but in the presence of water vapor it creates sulfuric acid which corrodes concrete and mild steel. You’ll have a lot of water vapor since the wastewater will be hot. Make sure to use a coating on all concrete surfaces and avoid mild steel and cast iron in all brewery wastewater applications — especially tanks and sump pumps.

With respect to the concentration of BOD and TSS, things start getting tricky. Generally speaking, domestic wastewater has a BOD and TSS of about 150 mg/L. Plain ol’ brewery wastewater can have a BOD of about 10,000 mg/L and a TSS of 5,000 mg/L. The way they remove the BOD at a wastewater treatment plant is with horsepower. We’ve all seen big tanks and ponds of bubbling wastewater at treatment plants. What’s going on is aeration, adding oxygen to the water to promote bacteria growth; these bacteria consume the BOD. A higher BOD wastewater requires more aeration, more horsepower, and at the end of the day a higher electricity bill. Additionally the bacteria die and have to be disposed of as sludge; more BOD equals more sludge.

In a brewery’s case, most BOD cannot be filtered out, we’re talking about sugar and alcohol. The TSS can be filtered out, but in both cases the best option is to not put it down the drain in the first place. Side stream those high BOD and TSS loads, things like trub, spent yeast and waste beer, and truck that stuff off site as fertilizer. Doing this one fairly simple task can lower your BOD and TSS by about 80 percent, saving money with reduced surcharges. Of course you will have to pay hauling and management fees to do this, but in areas with tight wastewater restrictions an 80 percent reduction is a very big deal.

In addition to side streaming, there are a few other simple ways to keep solids out of the wastewater. One is to keep screens in the drains. This isn’t as easy as it sounds. Screens plug, workers will take them out to clean them and will often “forget” to put them back in. Can’t blame them, no one wants to mess with this. Using the correct gauge of screen helps as well as making it easy to access. Another really simple thing is to make sure workers don’t dump these solids down the drain, like they would at a kitchen sink. One last simple step is if you have a wastewater tank downstream, use a basket at the end of the line to catch big things like wrenches, pallet chunks, bottles, caps, and shrink wrap. If the basket plugs make sure it can simply overflow in to the tank.

What if your regulatory people are befuddled with brewery wastewater, or maybe you can’t talk in terms they can understand? Does dilution solve all of your problems? First of all, dilution doesn’t help and it’s often illegal. Imagine this scenario. You have a keg of beer to get rid of. You can dump the beer down the drain, or you can put the beer in 1,000 gals of water and dump all of that down the drain. The concentration is very different, but the nutrient value (load) is the same.

Loading is a term wastewater operators use when talking about capacity of a treatment plant. Load is a factor of concentration and volume. BOD and TSS loading is calculated the same way, and it’s expressed in pounds:

(8.34 * BOD (in mg/L) * gallons)/1,000,000

8.34 = pounds of water in a gallon

1,000,000 = how many milligrams are in a liter of water

If your wastewater has a BOD of 2,000 mg/L and you have 10,000 gallons of it, you have 167 pounds of BOD. Not super valuable to you, but now you are talking in terms wastewater people can understand.

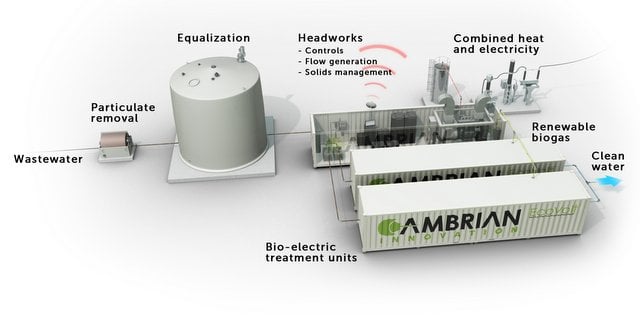

Trouble really starts if your brewery is in a small town with a small treatment plant, and you want to expand. You might have to start looking at treating your wastewater on site, and this is a game you do not want to get play if you don’t have to. Tail wags to dog so to speak, or at least it can. What business are you in, brewing beer or treating wastewater? These lines blur if you have a treatment plant on site. There are a lot of cool options out there, some work and some might. Before looking at any of them, make sure you have done everything you can to utilize the city’s existing infrastructure and personnel. Talk to an independent engineer or consultant with brewery experience (like myself), if you talk to a supplier about equipment you will get a sales pitch and of course it’ll sound good, but will it really save you money?

One last nugget. In the world of brewery utilities, calculating and tracking usage on a per barrel basis is a hugely valuable tool. For instance, last month you:

Brewed 500 barrels (bbl)

Purchased 80,000 gallons of fresh water from the city,

Discharged 50,000 gallons of water to the sewer, and

Purchased 300,00 kWh of electricity.Your ratios were:

5 bbls of water per bbl brewed (80,000/500/31),

(or 5 pints of water per pint brewed)

3 bbls of wastewater per bbl brewed, and

19 kWh of electricity per bbl brewed.

(31 = gallons of water per bbl)

Are these factors high or low? Who cares. Just start tracking usage. You can track usage per barrel brewed, sold, or packaged. Just make sure to do it the same every month. You can also track therms of natural gas, man hours, pounds of solid waste, side stream water, or dollar values of all of these things…

You can also turn these formulas around to forecast wastewater loading. If you expect 3 bbls of wastewater per barrel brewed, and you expect to brew 300 bbls: 3 * 31 * 300 = 27,900 gallons. You can do the same with any factor above.

It takes a few minutes each month and in time you will notice trends. Eventually you’ll want to know if these values are high or low, and there established average values for craft brewers (see the Brewers Association or the articles mentioned in the bio above); but knowing your own values is more important. I urge you all to start tracking these numbers. Make a graph out of it on Excel. In time you will have the data to compare usage, set goals and create accurate budgets.

As you can see, there’s a lot to it. Who would have thought? It’s not rocket science, but it is science. Don’t reinvent the wheel, please talk to an expert if you have any questions (this writer always gives his first hour free for all potential clients).

John Mercer has been a licensed wastewater treatment plant operator in the State of Oregon from 1997 to 2014 and has more than 15 years of wastewater experience in breweries and laboratories. Visit his website right here. He worked at Deschutes Brewery in Bend, Ore., from 1998 to 2010 where he operated, maintained and managed the waste treatment facility (WTF) at the production brewery — among many other things. In addition to designing and operating the large production plant wastewater system, he also designed and installed a small fully automated pretreatment system at Deschutes brewpub downtown. Since leaving Deschutes, he has designed many small brewery wastewater systems. In addition to brewery work, Mercer operates his own organic farm and ranch in Montrose, Colo. Pigs, chickens, cattle, vegetables and brewery consulting — plus a baby girl. Now that’s a full plate, so cheers for this article John.

Andrew Kennedy liked this on Facebook.

Wastewater 101 for brewers >> Wastewater basics for a growing craft brewery http://t.co/DYSjJlHBGn @CraftBrewingBiz @brewerywastewat

Wastewater basics for a growing craft brewery http://t.co/oUdyRMNPAr

Kathy Volpone Madison liked this on Facebook.

Wastewater basics for a growing craft brewery http://t.co/mLswjWCAMT via @craftbrewingbiz