Water, water everywhere, but not all of it will make the same beer. Some of the craft brewing industry’s largest companies are dealing with those water quirks as they expand eastward. Oskar Blues, for example, detailed (in this article) just how noticeable the difference was between beers brewed in their home of Colorado and their new digs in North Carolina. In Colorado, Oskar Blues is dipping into mountain runoff water, and in North Carolina, they are using local municipal water that is treated with a bit more chlorine than they are used to.

The beer created from the N.C. water isn’t necessarily bad, but it’s certainly inconsistent, and Oskar Blues has had to vigilantly work to remove those differences. Pretty interesting comments from the team on what their process is out east:

Every day, a half-dozen employees of Oskar Blues Brewery file into a small room in Brevard, N.C. It’s cluttered with boxes, petri dishes and test tubes.

This isn’t quite a chemistry classroom. There are beer cans and pint glasses. It’s a tasting area, where a sensory panel meets daily to try the beer. David Morris is scribbling notes about what he and his colleagues taste.

The staff also does blind tests, comparing its North Carolina-made beer with samples from Colorado, where the company started.

…

“…And what we found here is there’s quite a bit more chlorine. And so we’ve had to put in a charcoal filtration to remove the chlorine,” Baumann says.

Be sure to read the feature on WYPR.org for more examples of craft breweries treating their water for consistency.

Other water quality resources

If your brewing team is in need of a brush up on water chemistry, check out Water: A Comprehensive Guide for Brewers, from Brewers Publications which is solely devoted to the use and treatment of water throughout the brewing process. The book includes an overview on sources, quality and geography, and it shows brewers how to read water reports, understand flavor contributions and adjust the chemistry of brewing water.

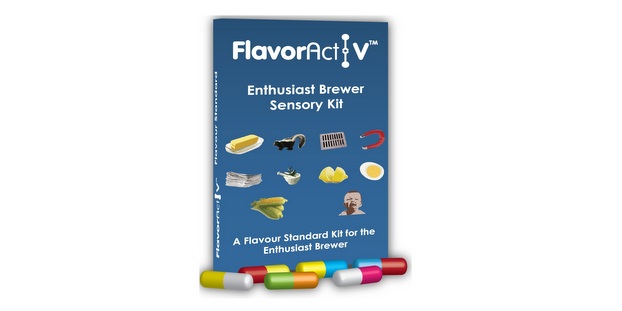

Another resource from FlavorActiV is a comprehensive range of Good Manufacturing Practice (GMP) Water Flavor Standards to complement the GMP Beer Flavor Standards to help breweries test for impurities. Flavors from sweet apple to inky chemical will have a detrimental effect on the end product, so being able to detect and remove in advance will save considerable time and money later.

John Brothers liked this on Facebook.

Grow More Hops liked this on Facebook.

Summer Sun Garden & Brew liked this on Facebook.

Oskar Blues shares their new water treatment process http://t.co/QAvYdharwY via @craftbrewingbiz

Lorraine Deffenbaugh liked this on Facebook.