Sure, our Master Maltsters feature story was packed with malt market info and supplier tips for craft brewers, but did you know that for every insight-packed Craft Brewing Business feature there are nuggets of info that are left on the cutting room floor? It’s not that this information isn’t valuable. Often times, it just doesn’t quite fit into the narrative flow of the story. Here at CBB, we don’t like to see anything go to waste; so, we collected a bunch of leftovers from the malt feature story. If you haven’t already, be sure to read the Master Maltsters feature story to get the full picture. Enjoy!

Featured company profiles

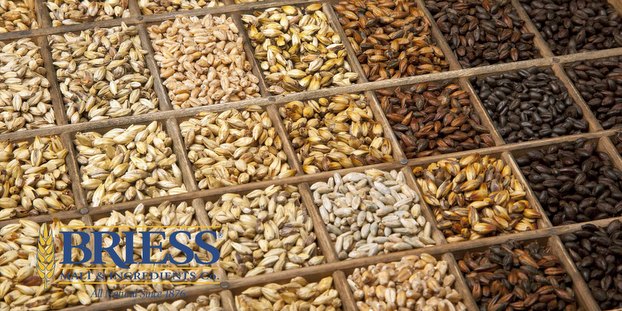

Briess Malt & Ingredients Co. (Chilton, Wis.)

Briess has been a family-owned malting company since 1876. When Ignatius Briess started malting barley in their original Czechoslovakian malthouse, he and his son Rudolph developed a sizable export business. Then war disrupted their malting operations, so his grandson Eric came to the United States to continue supplying customers from here. It wasn’t long before caramel malt was being produced, something of a prelude of what was about to happen with the American Craft Beer movement. In the 1970s, after Eric died, his son Roger took over the company, completely embraced craft brewing and dedicated company resources to it. He was a European trained, fourth generation maltster/brewer. Roger changed the company’s focus from export to producer of specialty malts for American craft beer. Of course Briess still exports, but its focus is supporting craft beer in the United States.

Cargill (Minneapolis)

Cargill entered in to the malting business in 1979. The company has relationships with global maltsers to provide brewers access to the highest-quality malts – including Dingeman’s fine Belgian malts. Cargill’s worldwide malt network includes malting facilities in strategic proximity to the premier barley-growing regions in Europe and the Americas. This geographical connection aims to tap the best available malting barley. Cargill supplies domestic and imported bulk malt and specialty malts including base malts, specialty brewers malts, clear malt, diastatic malts and distillers malt, as well as filter aids, adjuncts and sorghum syrup.

Weyermann® Malting Co. (Bamberg, Germany)

A family-owned and family-run malting business since 1879, the company started out as a small local supplier of malt for markets in Bamberg and environs. It has since grown to become a world market leader in specialty malts, producing the one of the largest portfolio of malts — some 80 varieties — and serving customers in 135 countries. It has been a staple in the brewing community, attending every Craft Brewers Conference since 1996. The company makes a point to continue to engage with their customers face-to-face.

What’s in style?

Bob O’Connell, vice president of sales and marketing, Briess Malt & Ingredients Co.: “A big share of American craft beer volume growth is in IPAs, wheat, lighter-flavored session beer styles and seasonals. In the world of specialty malts, that translates into increased demand for high-quality specialty malts so craft brewers can put signature flavors and colors on these beer styles. At Briess, three malts introduced in the past several years are seeing significant use partly due to this trend—Goldpils Vienna Malt, Blackprinz and Midnight Wheat. The last two are really good examples of new, unique specialty malts that brewers use at low usage rates for subtle to pronounced flavor and color contributions.”

Sabine Weyermann, chief executive officer of Weyermann® Malting Co.: “Malt-makers have benefited greatly from the quest by innovative craft brewers for more and more specialty malts. This demand extends from different caramel malts, roasted malts of varying colors and flavor intensities, highly aromatic malts, acidulated malts, old-fashioned, floor-malted, artisanal malts; to diastatic malts, to melanoidin malts; and many, many more. What has emerged in the process is a wonderful symbiosis: A growing global beer diversity has spawned an equally broad malt diversity; while a growing malt diversity has given innovative craft brewers the tools to create new beer styles that had hitherto not been thought of. Just think of Double American Imperial IPA, Black IPA, Abbey Quadruple or Belgo-American Sour Ale.”

Jeff Milligan, NA Commercial Manager — Malt, Cargill: “Of course, there is increasing interest in new offerings. Everything from unique barley to special malts are gaining traction. The industry also definitely has an affinity for the barley grower, and the grower stories drive some of their sales. On the other hand, there is additional interest in darker malts and a good balance between roasted and kilned, domestic and imported malts as well. The range speaks to the diversity of beer styles and the never-ending innovations in brewing.”

Malt history and craft brewing

““Of course, there is increasing interest in new offerings. Everything from unique barley to special malts are gaining traction. The industry also definitely has an affinity for the barley grower, and the grower stories drive some of their sales.” — Jeff Milligan, NA Commercial Manager — Malt, CargillWeyermann: “When the craft brew movement was still in its infancy, many industry observers considered craft beer just a fad and not the beginning of the type of revolution that it eventually turned out to be. My husband Thomas Kraus-Weyermann and I got our first impression of craft beer at the 1996 Craft Brewers Conference, which was then held in Boston. We immediately decided that this movement was for real and we had to be part of this pioneering revolution. We figured that what these craft brewers wanted to achieve in their brewhouses was a perfect match to what we tried to achieve in our malt house. Thus, we searched for an American distributor and started shipping 25-kg bags — a novel packaging system at the time — filled with our large variety of specialty malts, many of which were quite unknown to American brewers.”

O’Connell: “As an industry, U.S. maltsters and some breweries banded together years ago to form the American Malting Barley Association. Membership fees pay for research and development of new varieties that not only perform well for breweries, but are more disease resistant with higher yields to help encourage growers to plant barley for malting. This has been a step in the right direction. But more needs to be done. This year Briess took another step to increase U.S. barley plantings with the purchase of a large barley procurement operation in Wyoming. At capacity, the facility can process more than 4 million bushels during harvest and, at anytime, store up to 2.5 million bushels. Working with a network of 200+ barley growers in the region, Briess plans to increase production to capacity. Briess also purchased a seed plant to assure purity of seed, and a nearby barley crop research center is being used for continued development of new malting barley varieties.”

A malt for different season(al)s

Weyermann: “We have tried to match the brewers’ creativity with our maltster’s creativity. In this context, we are particularly proud of our most recent — and growing — series of innovative ‘heirloom and terroir’ malts, some of which are based on grain varieties whose genetic roots can be traced centuries back. For instance, we resurrected a smoked wheat malt variety that is needed for an authentic Grätzer Beer from what is now the Polish City of Grodziski. We still make several malts from a classic barley variety called Barke, which produces one of the finest malt aromas of any barley variety but is now rarely planted, mostly for agronomic reasons. Then there are our hand-made floor-malted specialty malts for which we rely on the classic Czech varieties of Bojos and Tolar, which can trace their origins back to the original ‘Old-Haná Agro-Eco-Type’ that was used in the first Pilsner mash in 1842.”

International style

The craft beer industry’s hottest trends can often be seen by reading the agricultural tea leaves. In barley’s case, demand for U.S. vs. international malt brands is mainly driven by the style of beer that the brewer is brewing, as well as the story behind the beer. Although, the base malts used in the United States are primarily domestic, explained Milligan. The balance between United States and imported really comes into play with the small percentage of specialty malts.

“Typically, commercial American craft brewers know the quality and flavor is there, so for most, malt is selected not for country-of-origin but rather quality, freshness, availability, service and price,” O’Connell said. “Using domestic, made close-to-home malt is also very important for brewers dedicated to environmental stewardship. In Wisconsin, for example, breweries like Central Waters, New Glarus, Stone Arch and Fox River make locally sourced malt a key part of their corporate plans and marketing platforms.”

Weyermann agreed that flavor characteristics and consistency, as well as the quality of the raw materials, are more important to modern craft brewers, who make high-value beers, than are the origins of these raw materials.

“This is why craft brewers often use not just specialty malts from Germany, but also from the U.K. In hops, incidentally, the situation is the same,” Weyermann said. “Craft brewers are just as likely to use Saaz from the Czech Republic, East Kent Golding from the U.K., Aurora from Slovenia, Strisselspalt from Alsace in France, or Nelson Sauvin from New Zealand, as they are to use Willamette from Oregon or Cluster from Washington State. When it comes to ingredients, innovative craft brewers are true cosmopolitans, nowadays.”

RT @CraftBrewingBiz: The Mash: Outtakes and extra info from our talks with #malt experts http://t.co/DPJR2xf2fK #sundayreading

The Mash: Outtakes and extra info from our talks with malt experts @CraftBrewingBiz http://t.co/2WNqQl8ol4

Brewery Insurance Program liked this on Facebook.