Tröegs Brewing Co. has eleven beers in its regular production portfolio. Three of those beers won gold medals at the 2012 Great American Beer Festival — HopBack Amber Ale, DreamWeaver Wheat and Sunshine Pils. That’s an impressive hat trick for any brewery in the world, so we wondered: What’s Tröegs’ secret to success?

We had to find out, so we called on the central Pennsylvania brewery for our Beer of the Month column to discuss their flagship craft beer — HopBack Amber Ale. Chris and John Trogner started Tröegs way back in 1997, and by 2011 the company was expanding into a new 90,000-sq ft facility in Hershey, Pa. The new facility was about three times the size of the original brewhouse, designed to be a unique craft beer experience for Tröegs’ guests, featuring a 5,000-sq ft tasting room that opens into an outdoor viewing area with ample sights of the brewhouse. Brewery goers can observe the brewing process first-hand by taking a self-guided tour along a window-lined hallway for an up-close view of the magic behind Tröegs’ beer.

We wanted our own behind-the-scenes tour of Tröegs, so we called on media and communications manager Jeff Herb to talk about the new facilities, award-winning beer and the secrets behind HopBack Amber Ale. Off we go.

Craft Brewing Business (CBB): Jeff, thanks for taking the time. We really appreciate it. Tröegs Brewing has a rich history. It was formally founded in 1996 by brothers John and Chris Trogner in Harrisburg, but moved to a brand new 90,000-sq ft facility in Hershey in fall 2011. Has the new facility met everyone’s expectations? How has production improved, and how much space do you have left to expand?

Herb: Everything in the new facility has been going extremely well. It took almost four months for all the tanks from Harrisburg to be brought online so we had some production issues when the facility opened, but we were still able to enjoy more than a 20 percent growth increase throughout the year, so we had the kind of year we expected. The new brewhouse is fully automated, which means that our brewers needed to learn a new system, but the brewhouse manufacturer BrauKon has been actively involved with us throughout the year, making sure the equipment is running as efficiently as possible.

We’ve ordered six more fermenters that will arrive this summer and fill out the fermentation space that we created in the new brewery. We do have several options moving forward with additional tanks as needed — either building a new cellar inside the brewery or pouring a pad outside the brewery and installing more tanks in the back of the building.

CBB: I noticed on your blog you’ve uploaded some photos of your new robotic bottling automation line. Is that being installed now? How will this automation improve your efficiency?

Herb: We are in the process of installing a new filler and packaging line for 12- and 22-ounce bottles, and the robotic arm is part of that project along with a new box shop, six pack line and sealer system. The new line will triple our production and hopefully eliminate a lot of down time that has become more common as our current bottling line, which is all used equipment accumulated over 16 years, continues to work harder and harder.

CBB: Let’s talk about your flagship craft beer — HopBack Amber Ale. Can you give us a little history on this beauty? When did you first brew it? How popular is it today?

Herb: HopBack Amber Ale was introduced in 2001 and has grown into our best-selling brand. HopBack Amber Ale replaced one of the brewery’s original brands — Tröegs ESB. ESB developed an early following among Tröegs drinkers, but as the brewery expanded ESB sales remained flat. As the brewery was continuing to evolve, changing the ESB recipe and re-branding the beer as HopBack Amber Ale is a pivotal moment in the brewery’s history. HopBack Amber sales immediately took off and the brand quickly became the brewery’s leader in sales. It got us a lot of traction in outside markets and paved the way for new brands like Tröegenator and Mad Elf, which were released just after HopBack Amber. HopBack remains a strong selling brand to this day.

CBB: HopBack is made specifically in a hopback vessel. Can you explain what that is and the unique brewing techniques for this particular beer?

Herb: We built a hopback vessel in Harrisburg as we were introducing this beer into the market. The original hopback was essentially a large strainer that we could fill with about 40 lbs of whole flower hops and let the hot wort pass through the vessel, which gave the beer a “green nose” or hoppy aroma and a burst of hop bitterness in the front of the beer. Over time, the hopback played a more integral role in all our beers, and we now run all our beers through the hopback — excluding Troegenator, DreamWeaver and Mad Elf Ale.

When we moved to Hershey, the hopback vessel had to be much larger and integrated into the brewhouse. The new vessel can hold up to 140 lbs of whole flower hops and has a lot more engineering involved to make sure the beers have a distinctive hop forward note, but the concept is still the same as the big stainless steel colander we used in the original brewhouse.

CBB: How many awards has HopBack won? Can you name a few?

Herb: HopBack Amber Ale has won numerous awards, the most significant being a gold medal at the 2012 Great American Beer Festival and a silver medal at the 2010 Great American Beer Festival.

CBB: Didn’t you guys win three gold medals at the 2012 Great American Beer Festival? For HopBack Amber Ale, DreamWeaver Wheat and Sunshine Pils? That’s pretty impressive. Do you feel you’re getting more national and international recognition lately? What do you attribute that success to?

Herb: We attribute the success to our brewers working really hard throughout the past year to master the beers we are making in the new brewhouse. The three beers you mentioned are all brewed on a regular basis, so you can’t brew a beer to specification simply to fit a GABF style. The beer’s got to be consistent, and to be honored for consistency should be a goal for any production brewery.

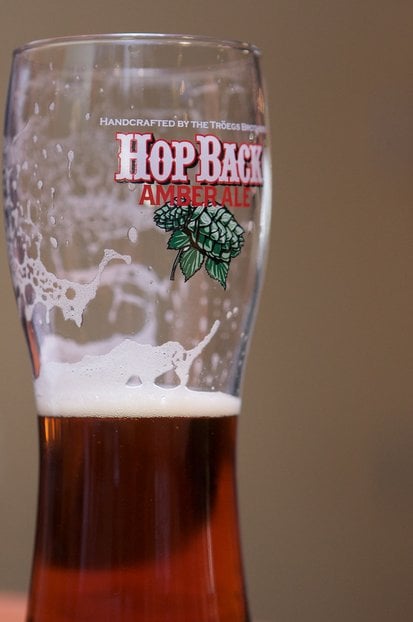

CBB: What are the main ingredients in HopBack Amber Ale? What types of malts and hops do you use? What type of yeast?

Herb: HopBack Amber Ale is brewed with Pilsner, Munich and Crystal malts. We use Cascade, Williamette and Nugget hops in the boil and Crystal and Nugget hops in the hopback vessel. We use our house ale yeast in our recipe for HopBack Amber.

CBB: What advice would you give an up-and-coming craft brewer when considering how to brew an amber ale product?

Herb: HopBack Amber Ale’s roots go back to John and Chris brewing on their back porch in Colorado. They have been playing around with the amber style forever. The ESB had amber roots, and when the beer was re-developed as HopBack, it magnified our take on the amber style. The hopback vessel is a key component to the flavor of the beer, but the goal has always been to create a spicy hop-forward beer that has a sweet malt backbone to balance the bitterness of the hops.

CBB: What marketing advice would you give a new brewing business when it comes to selling an amber ale? Why do you feel your product is so successful?

Herb: Believe in your year-round beers and let them guide the brewery. Everyone will always be excited about what’s new and what’s next, but a well-executed group of year-round beers should be the basis for any marketing plan. Seasonal and one-off beers will always lead to brand excitement, but keeping focus on those year-round brands is how you ultimately work to keep a brewery moving forward.

CBB: What’s next for Tröegs? We noticed your Scratch Beer Contest released a couple of weeks ago. You also do a lot of cool events and charity work. What cool new things do you see on the horizon for Tröegs?

Herb: Our business has always been focused on being a strong regional brewer, and our home market will always be a priority. However, you have to always be looking toward the future and staying current or ahead of the curve. We introduced Perpetual IPA this year, and it is growing quickly, so we need to be able to brew more of that beer and still continue to grow our year-round and seasonal brands. In 2014, we hope to start opening new markets and also start a new line of 750-ml corked and caged beers for sale throughout our distribution network.

Nice article about- Tröegs Talk: Discussing HopBack Amber Ale with Jeff Herb – Craft Brewing Business http://t.co/C3eQeXWdjM